Composition used for 3D printing, 3D printing material containing composition, preparation method and applications of 3D printing material as well as 3D printing equipment

A 3D printing and composition technology, applied in the field of 3D printing materials, can solve the problems of not developing functional directions, and achieve the effects of low cost, high safety and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

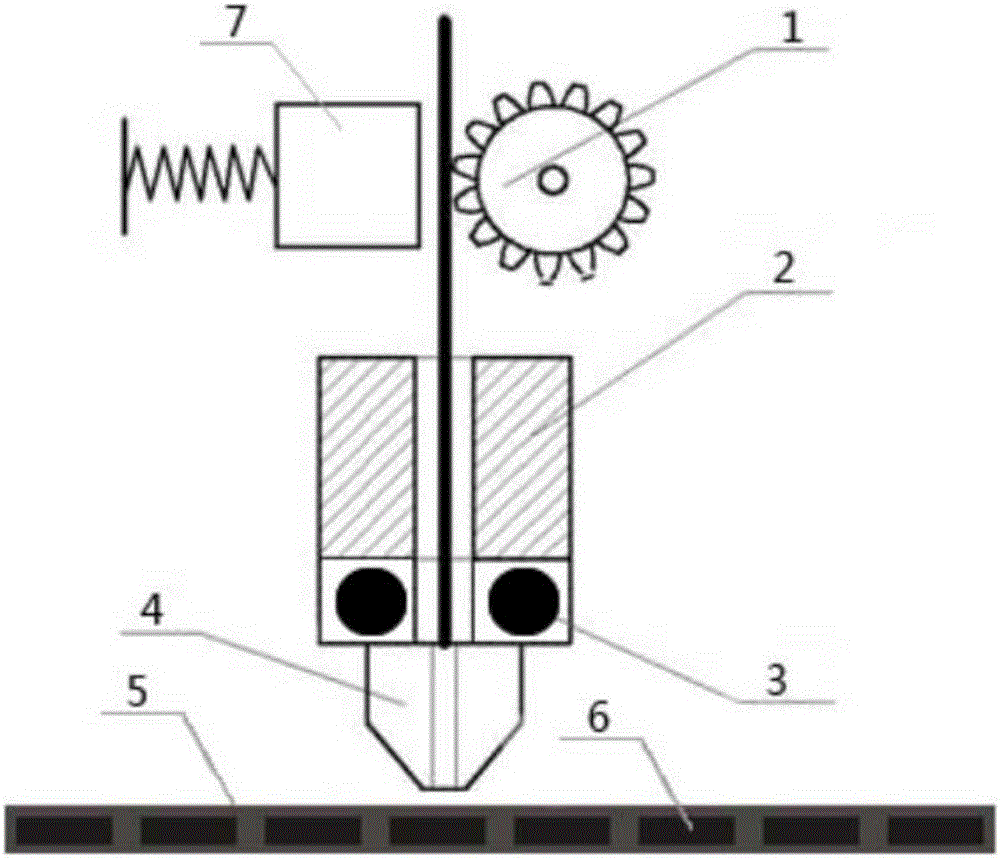

[0073] The present invention also provides a method for preparing materials for 3D printing, comprising the following steps:

[0074] 1) mixing the components in the composition; preferably fully mixing by a high-speed mixer for 5 to 30 minutes;

[0075] 2) The mixture obtained in step 1) is melted and plasticized by a twin-screw extruder, and pelletized by a pelletizer; preferably, the melt-plasticized temperature of the twin-screw extruder is 60-150°C.

[0076] Further preferably, the preparation method also includes the following steps:

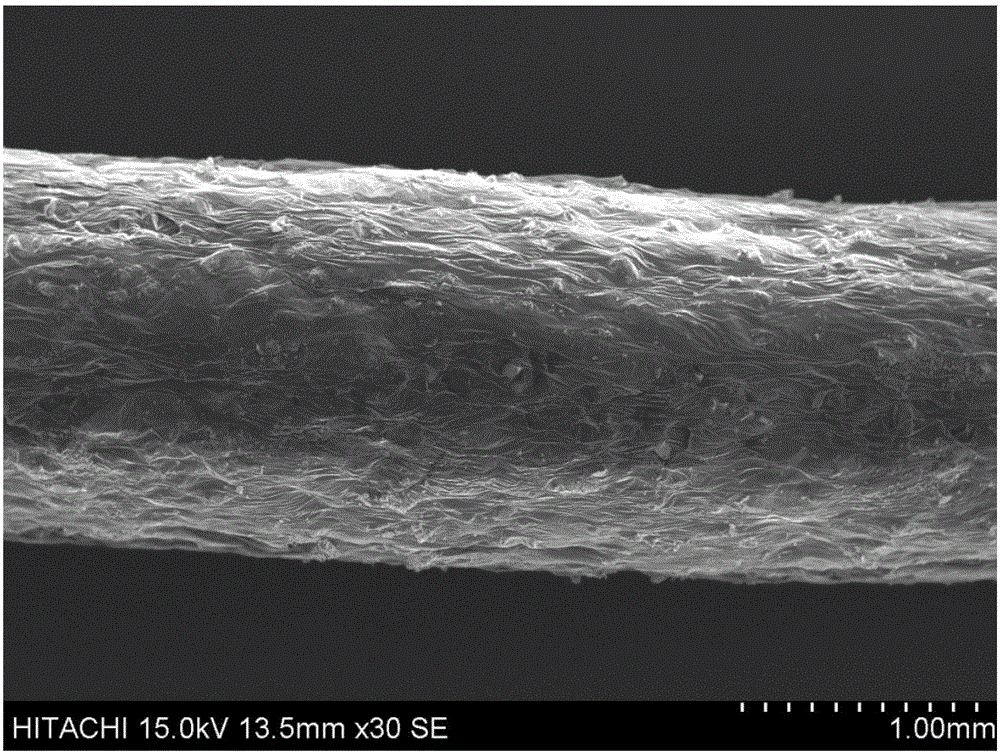

[0077] 3) drawing the pellets obtained in step 2) to obtain filaments; preferably drawing through a screw extruder; more preferably drawing through a single-screw extruder. The preparation method has simple process, low cost and high safety. The obtained filaments have a diameter of 0.5-5 mm, more preferably 1.5-3.5 mm, for example 1.75 mm or 3 mm.

[0078] According to the present invention, before mixing the thermoplastic resin in the...

Embodiment 1

[0091] 1. According to the following proportions by weight:

[0092] Perstorp Capa TM 6400 (the number average molecular weight is 37000) 40 parts;

[0093] SM 2 Fe 17 N 3 46 parts of powder;

[0094] Toughener DowPOE84115 parts;

[0095] Tackifier C 9 Petroleum resin (provided by Puyang Hengfeng Petrochemical Co., Ltd.) 8 parts;

[0096] German BASF antioxidant 1680.5 parts;

[0097] Nanjing United Silicon Chemical KH5700.5 copies.

[0098] 2. Preparation method

[0099] 1) The raw materials are weighed in proportion;

[0100] 2) Ball mill the PCL pellets in a liquid nitrogen environment for 1 hour to obtain a powder with a particle size of about 200 μm; at the same time, disperse the silane coupling agent KH570 in the Sm 2 Fe 17 N 3 in powder;

[0101] 3) Put the above components into a high-speed mixer and stir for 10 minutes at high speed, and mix thoroughly;

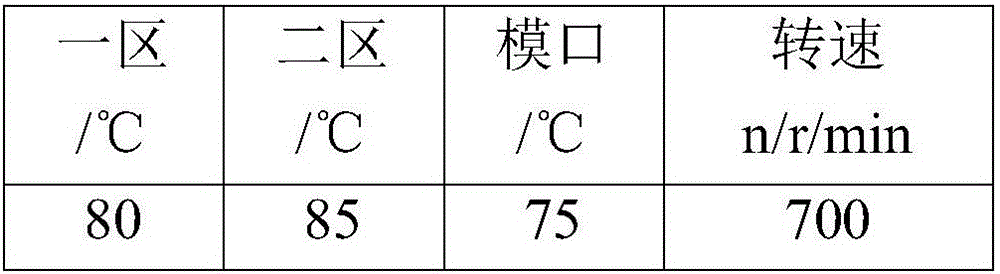

[0102] 4) Put the mixture obtained after fully mixing in step 3) into a HAAKE twin-screw extruder ...

Embodiment 2

[0109] 1. According to the following proportions by weight:

[0110] Perstorp Capa TM 6500 (the number average molecular weight is 50000) 28 parts;

[0111] Nd 2 Fe 14 62 parts of B powder;

[0112] Toughening agent DupontEVA2603 parts;

[0113] C 5 Petroleum resin (provided by Puyang Hengfeng Petrochemical Co., Ltd.) 6.2 parts;

[0114] BASF antioxidant 1680.5 parts;

[0115] Nanjing United Silicon Chemical KH5600.3 parts

[0116] 2. Preparation method

[0117] 1) Weigh the raw materials in proportion;

[0118] 2) Ball mill the PCL pellets in a liquid nitrogen environment for 1 hour to obtain a powder with a particle size of about 200 μm; at the same time, disperse the silane coupling agent KH560 in the Nd 2 Fe 14 In B powder;

[0119] 3) Put the above components into a high-speed mixer and stir at high speed for 10 minutes, and mix thoroughly;

[0120] 4) Put the mixture obtained after fully mixing in step 3) into a HAAKE twin-screw extruder for plasticizing and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com