Preparation and application of mesoporous silica/polyacrylonitrile core-shell nano-fiber films loaded with carbon quantum dots

A technology of mesoporous silica and nanofiber membrane, which is applied in measurement devices, fluorescence/phosphorescence, chemical instruments and methods, etc., can solve the problems of difficult separation and recovery of carbon quantum dot materials, and achieve good pH stability, preparation The method is simple, the effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

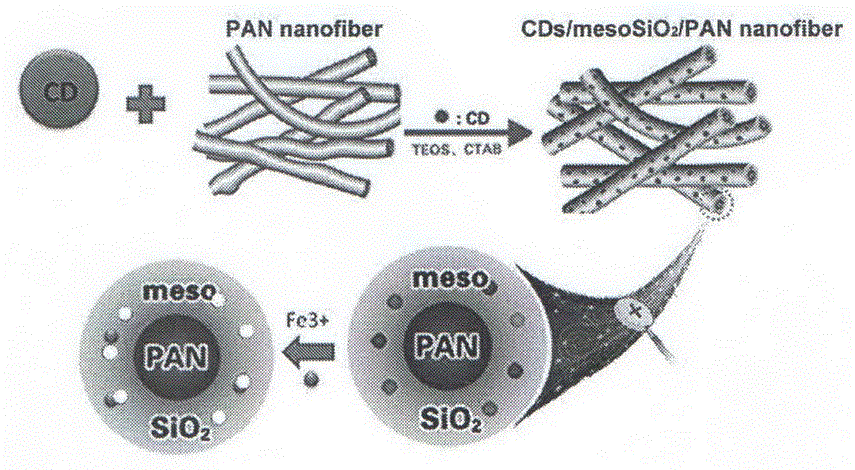

[0022] A, the polyacrylonitrile nanofiber film that molecular weight is 50,000 is immersed in the ethanol that mass ratio is 1:0.2: Carry out ultrasonic in the mixed solution of water;

[0023] b. During ultrasonication, add cetyltrimethylammonium bromide, carbon quantum dot solution, ethyl tetrasilicate and ammonia water with a concentration of 27wt% to carry out sol-gel by mass ratio of 1:0.2:0.5:0.5 reaction to obtain a mesoporous silica / polyacrylonitrile nanofiber membrane mixture with carbon quantum dots immobilized on the outer surface;

[0024] c, the resulting mixture was stirred for 1 hour at room temperature to continue the sol-gel reaction;

[0025] d. The mixture in step c is refluxed and washed 3 times in ethanol-hydrochloric acid solution with a mass ratio of 1:0.05 to remove the mesoporous pore-forming agent to obtain mesoporous silica / polyacrylonitrile core-shell loaded with carbon quantum dots nanofibrous membrane.

Embodiment 2

[0027] A, the polyacrylonitrile nanofiber film that molecular weight is 100,000 is immersed in the ethanol that mass ratio is 1:1: carry out ultrasonic in the mixed solution of water;

[0028] b. During ultrasonication, add hexadecyltrimethylammonium bromide, carbon quantum dot solution, tetraethyl orthosilicate and ammonia water with a concentration of 27wt% in a mass ratio of 1:1:2:2 to carry out sol-gel reaction to obtain a mesoporous silica / polyacrylonitrile nanofiber membrane mixture with carbon quantum dots immobilized on the outer surface;

[0029] c, the obtained mixture was stirred for 6 hours at room temperature to continue the sol-gel reaction;

[0030] d. The mixture in step c is refluxed and washed 7 times in ethanol-hydrochloric acid solution with a mass ratio of 1:0.2 to remove the mesoporous pore-forming agent to obtain the mesoporous silica / polyacrylonitrile core-shell loaded with carbon quantum dots nanofibrous membrane.

Embodiment 3

[0032] A, the polyacrylonitrile nanofiber film that molecular weight is 150,000 is immersed in the ethanol that mass ratio is 1:0.5: carry out ultrasonic in the mixed solution of water;

[0033] b. During ultrasonication, add cetyltrimethylammonium bromide, carbon quantum dot solution, tetraethyl orthosilicate and ammonia water with a concentration of 27wt% at a mass ratio of 1:0.5:1:1 to carry out sol-gel reaction to obtain a mesoporous silica / polyacrylonitrile nanofiber membrane mixture with carbon quantum dots immobilized on the outer surface;

[0034] c, the obtained mixture was stirred for 3 hours at room temperature to continue the sol-gel reaction;

[0035] d. The mixture in step c is refluxed and washed 5 times in the ethanol-hydrochloric acid solution with a mass ratio of 1:0.05-0.2 to remove the mesoporous pore-forming agent CTAB to obtain mesoporous silica / polypropylene loaded with carbon quantum dots Nitrile core-shell nanofiber membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com