Plant drying and essential oil and hydrolat extraction system based on air energy

An extraction system and air energy technology, applied in the direction of biomass drying, dry solid materials, essential oils/fragrances, etc., can solve the problems of high equipment manufacturing costs, lower product quality, complex equipment structure, etc., to achieve convenient operation and maintenance, improve The effect of high product quality and equipment integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

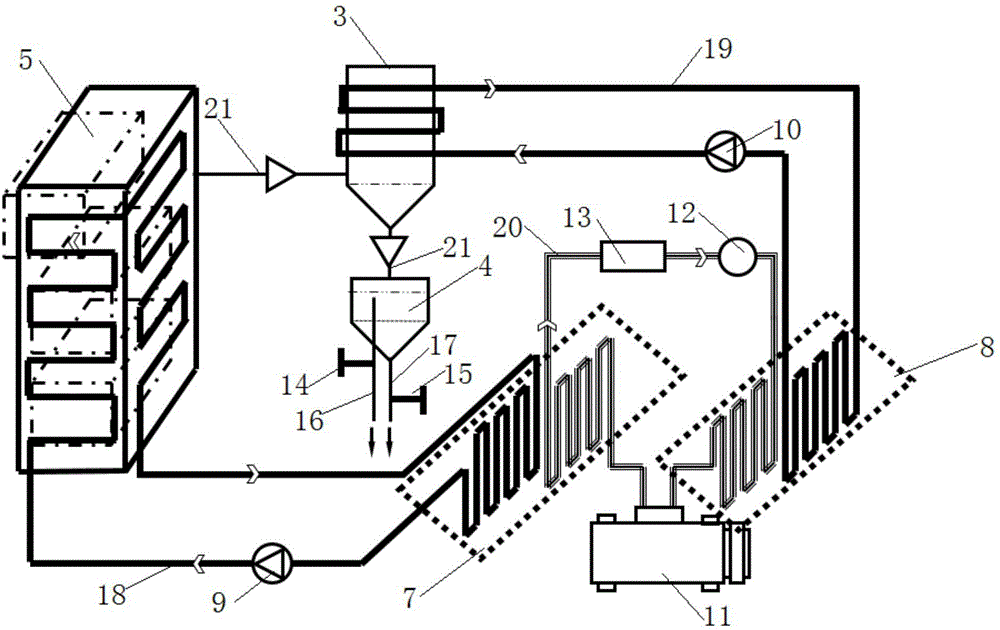

[0036] A plant drying and essential oil and pure dew extraction system based on air energy, such as image 3 As shown, it includes a plant drying unit, an essential oil, a pure dew extraction unit and an air energy heating and cooling unit. The plant drying unit is a drying box 5, which is used to dry the plants, and vaporize and volatilize the water and essential oils in the plants to form an oil-water gaseous mixture; The essential oil and pure dew extraction unit includes a connected condenser 3 and an oil-water separator 4, the condenser 3 is connected with a drying box 5, and is used to lower the temperature of the gaseous mixture into a liquid state, and the oil-water separator 4 is used to separate the liquid mixture into Essential oil and pure dew; the air energy heating and cooling unit includes a first heat exchanger 7, a second heat exchanger 8 and a refrigerant circuit; the first heat exchanger 7 includes a heating water pipe 18 and a refrigerant heat exchange pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com