Flue gas recirculation sludge spouted fluidized bed incineration system and method

A spouted fluidized bed and flue gas circulation technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems affecting the normal operation of the incinerator, blockage of the air distribution plate, and the economic reduction of the incinerator, etc. The effect of temperature, preventing coking in the furnace, and high specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

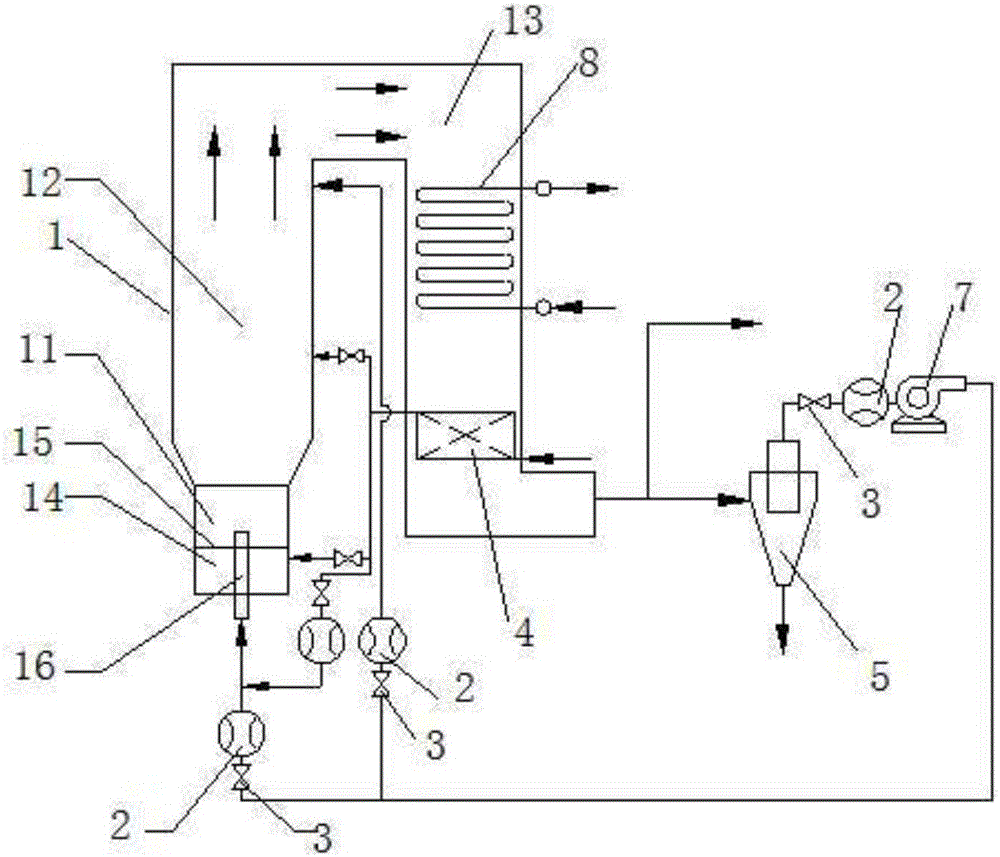

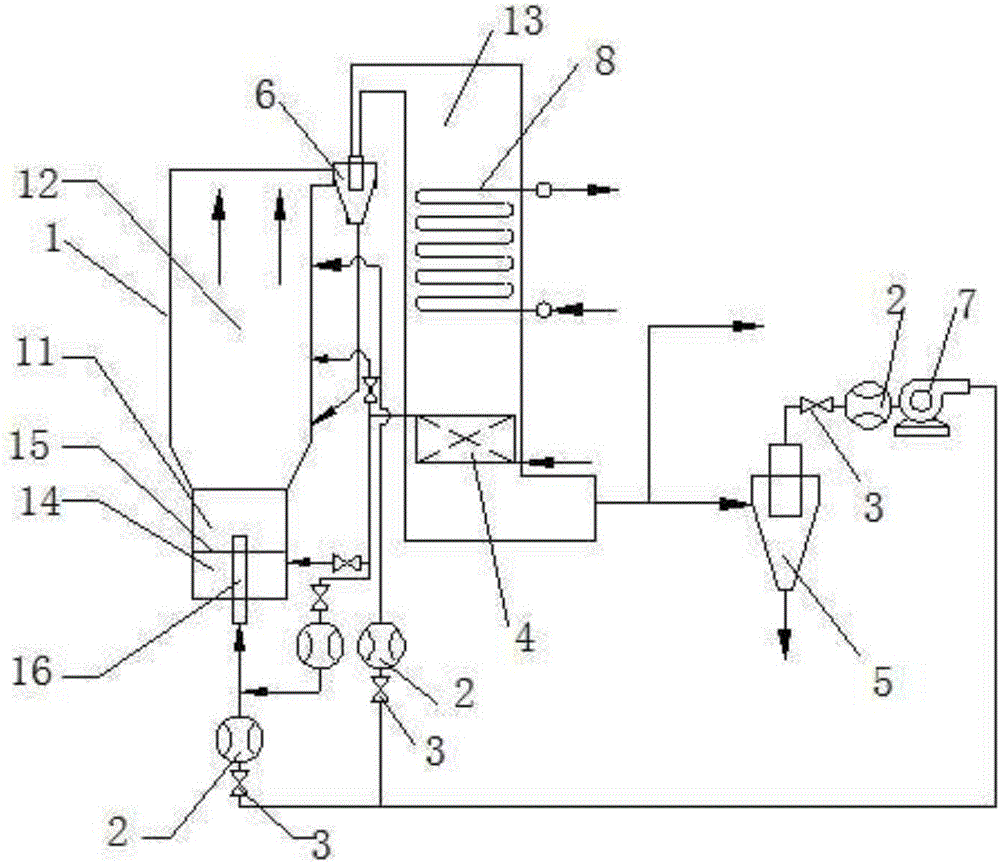

[0031] Such as figure 1 or figure 2 As shown, this embodiment provides a flue gas circulating sludge sprayed fluidized bed incineration method, including: when the fluidized bed incinerator 1 is incinerated, part of the low-temperature flue gas and part of the primary air are blown by the sprayed wind Introduce the incineration dense-phase zone 11 in the form of incineration, so that the incineration dense-phase zone 11 is in a spray fluidized state; the remaining part of the primary air is introduced into the incineration dense-phase zone 15 through the air distribution plate 15; the remaining part of the low-temperature flue gas is introduced into the incineration dilute-phase zone 12 The area near the flue 13; wherein, the total flow ratio of the primary air to the low-temperature flue gas is 0.48-0.96:1.

[0032] The above technical solution is the core technical solution of the flue gas circulating sludge sprayed fluidized bed incineration method of the present inventio...

Embodiment 2

[0038] Such as figure 1 As shown, the present embodiment provides an incineration system using the above-mentioned incineration method, including a fluidized bed incinerator 1, which includes an incineration dense-phase area 11 and an incineration dilute-phase area 12, and the lower part of the incineration dense-phase area 11 is provided with a Plate 15, an air chamber 14 is arranged below the air distribution board 15; the remaining part of the primary air inlet is arranged on the air chamber 14; a nozzle 16 is also included, and the nozzle 16 passes through the air chamber. The chamber 14 and the air distribution plate 15 make the nozzle of the nozzle 16 located in the incineration dense-phase area 11, and the other end communicates with part of the low-temperature flue gas inlet and part of the primary air inlet; The remaining low-temperature flue gas inlet is provided in the area 12 and close to the flue 13 ; the incineration dilute phase area 12 communicates with the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com