Organic waste water treatment apparatus, organic waste water treatment method, and control program for organic waste water treatment apparatus

A technology for organic wastewater treatment and water treatment, applied in water treatment parameter control, biological treatment adjustment methods, biological water/sewage treatment, etc., can solve labor and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

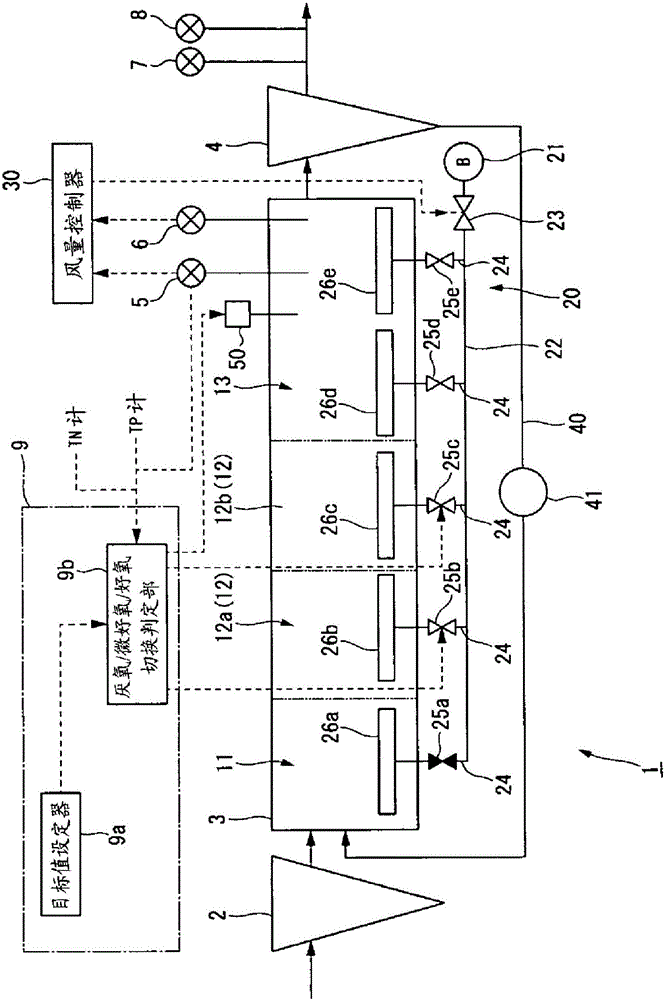

[0025] figure 1 The shown organic wastewater treatment apparatus 1 of the present embodiment includes a first sedimentation tank 2 , a biological reaction tank 3 , and a final sedimentation tank 4 in this order from the upstream side.

[0026] The biological reaction tank 3 is a reaction vessel for purifying sewage by the decomposition action of microorganisms. An anaerobic treatment zone 11 , an adjustment zone 12 , and an aerobic treatment zone 13 are provided in the biological reaction tank 3 . The adjustment area 12 is provided between the anaerobic treatment area 11 and the aerobic treatment area 13 . Here, "arranged between" does not mean a spatial concept but means that the order of treatment in the adjustment zone 12 is between the anaerobic treatment zone 11 and the aerobic treatment zone 13 .

[0027] The biological reaction tank 3 has an inflow part into which the organic waste water before purification treatment flows and an outflow part through which the organic...

no. 2 Embodiment approach

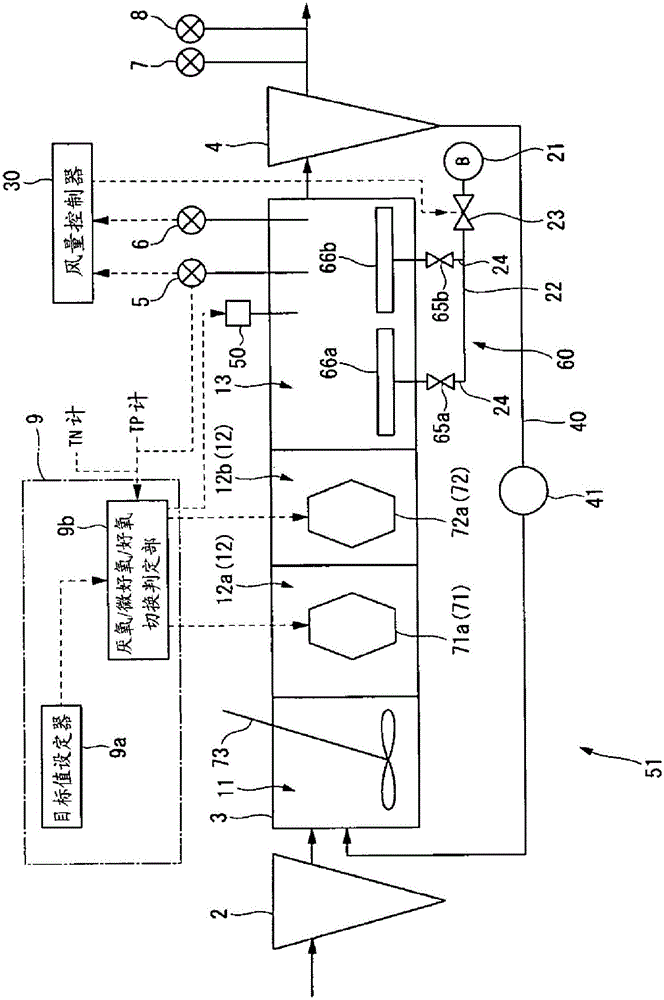

[0114] figure 2 The organic wastewater treatment device 51 of this embodiment is shown in . for with figure 1 The same constituent elements of the shown organic wastewater treatment apparatus 1 are denoted by the same reference numerals, and part of the description thereof will be omitted.

[0115] exist figure 2 The biological reaction tank 3 of the organic wastewater treatment device 51 shown is provided with an anaerobic treatment area 11 , an adjustment area 12 and an aerobic treatment area 13 . The adjustment area 12 is arranged between the anaerobic treatment area 11 and the aerobic treatment area 13 .

[0116] In addition, the bioreactor 3 is provided with an aeration device 60 as an aeration means. The aeration device 60 includes a blower 21 , an air pipe 22 extending from the blower 21 , a flow control valve 23 provided on the air pipe 22 , branch pipes 24 branched from the air pipe 22 , and on-off valves provided on each branch pipe 24 . 65a-65b, and air diffu...

no. 3 Embodiment approach

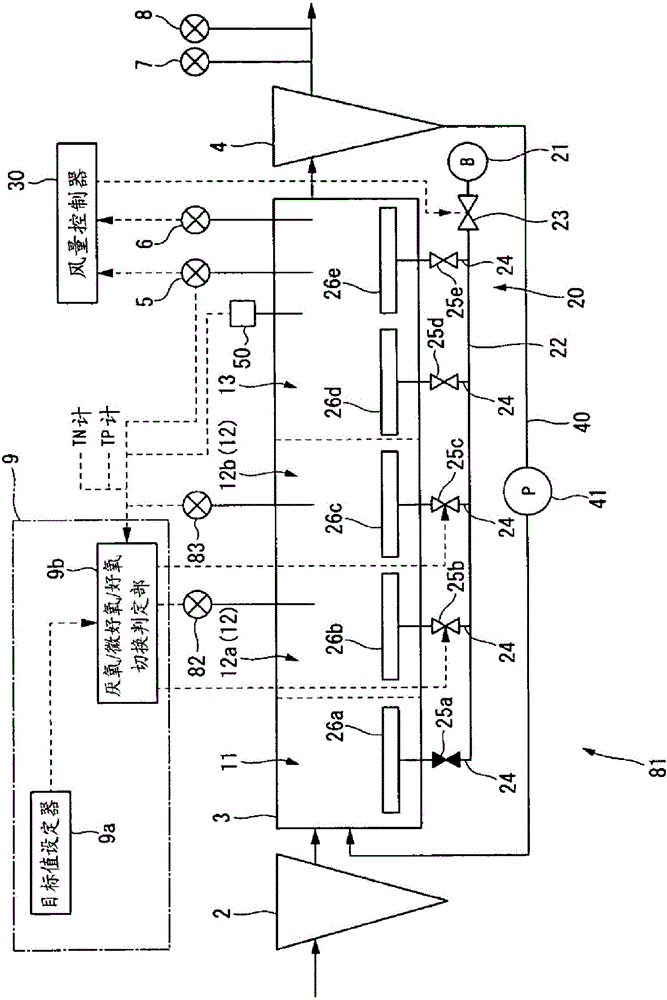

[0147] image 3 The organic waste water treatment apparatus 81 of this embodiment is shown in FIG. for and figure 1 The same components of the shown organic wastewater treatment apparatus 1 are denoted by the same reference numerals, and a part of the description thereof is omitted.

[0148] image 3 The organic wastewater treatment plant 81 shown is the same as figure 1 The organic wastewater treatment apparatus 1 of the first embodiment shown is different in that ORP meters (oxidation-reduction potential meters) 82 and 83 are provided in the first region 12a and the second region 12b of the adjustment region 12, respectively. In the present embodiment, when the atmosphere in the adjustment region 12 is controlled, the opening degrees of the on-off valves 25b and 25c are adjusted based on the oxidation-reduction potential of the treated water measured by the ORP meters 82 and 83 . That is, the control unit 9 finely adjusts the opening degrees of the on-off valves 25b and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com