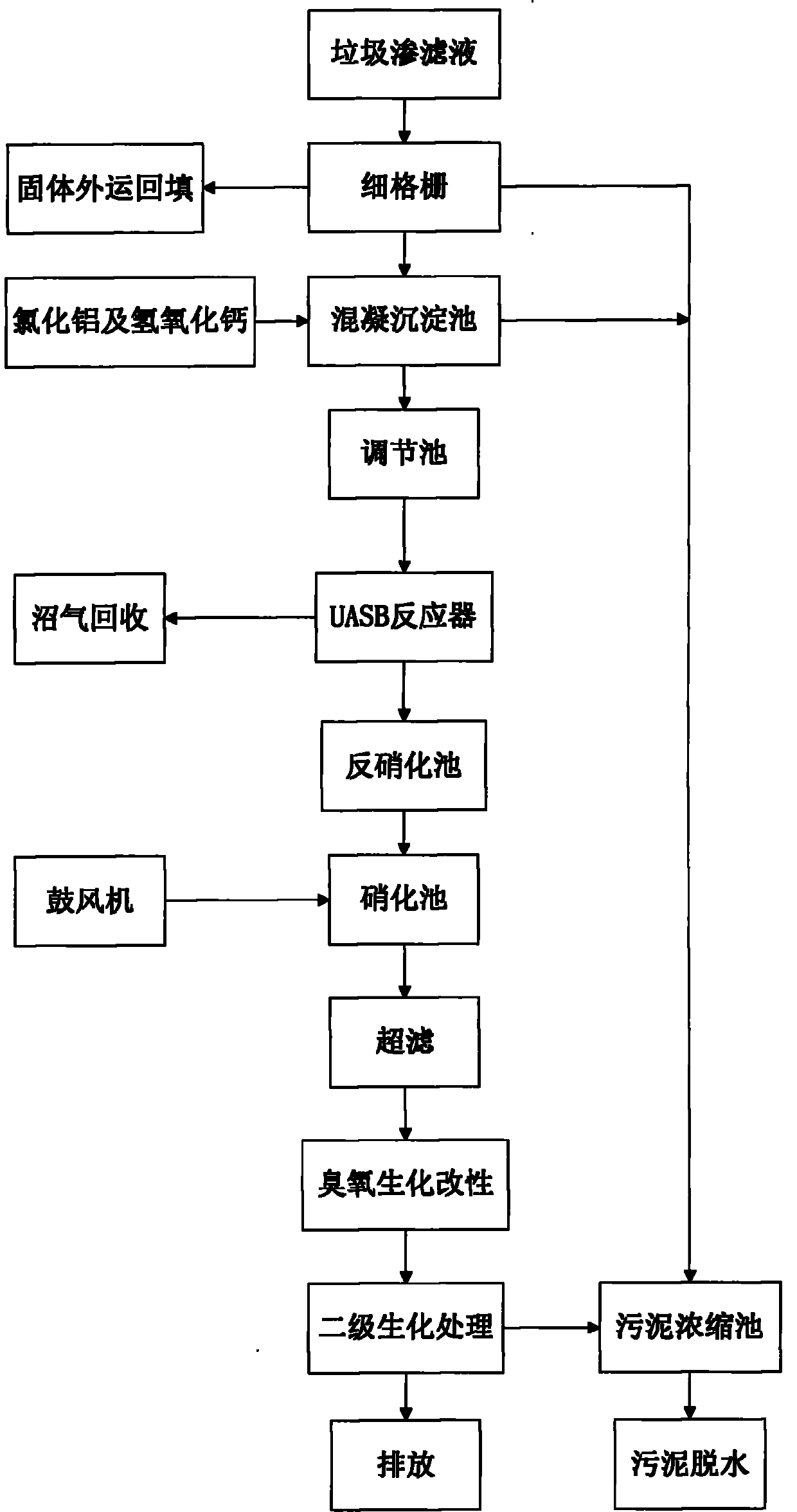

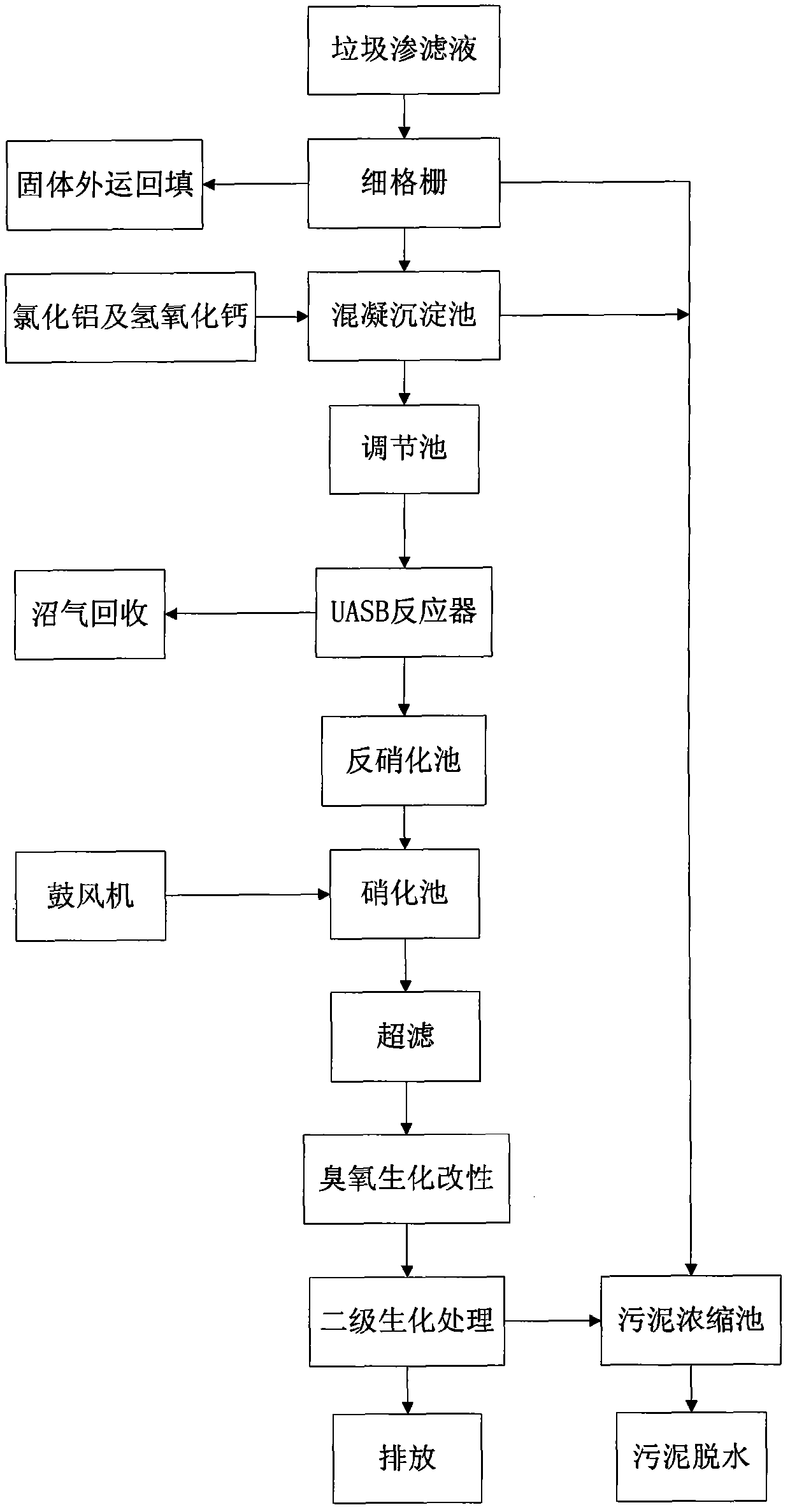

Garbage leachate treatment process

A technology of landfill leachate and treatment process, which is applied in the field of advanced treatment process of landfill leachate, which can solve the problems of inability to biochemically treat and achieve the effects of low operating costs, low investment, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0020] A treatment process for landfill leachate, the following process steps are taken:

[0021] (1) The landfill leachate is filtered through a fine grid, the solids in it are transported out for backfilling, and the liquid part enters the coagulation sedimentation tank;

[0022] (2), add polyaluminum chloride and calcium hydroxide in the coagulation sedimentation tank, and separate precipitation under the effect of mixer, the supernatant of gained enters the regulating tank;

[0023] (3), the supernatant of step (2) gained adjusts pH to neutrality through regulating tank;

[0024] (4), the neutral supernatant obtained in step (3) is pumped into the upward flow anaerobic sludge bed by the anaerobic circulation pump for treatment, wherein the biogas recovery is used to increase the temperature of the waste water, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com