Continuous evaporation crystallization system and method for one-step production of large-size food-grade potassium chloride crystals

A potassium chloride crystal, evaporation and crystallization technology, which is applied in chemical instruments and methods, evaporation, solution crystallization, etc., can solve the problem of not meeting the requirements of potassium chloride particle size and purity, small crystals of edible potassium chloride crystal products, and difficulty in drying Increase and other problems, to achieve the effect of continuous production, stable feeding and discharging, evaporation and crystallization process, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment is used to illustrate the food-grade potassium chloride crystal provided by the present invention and its production method.

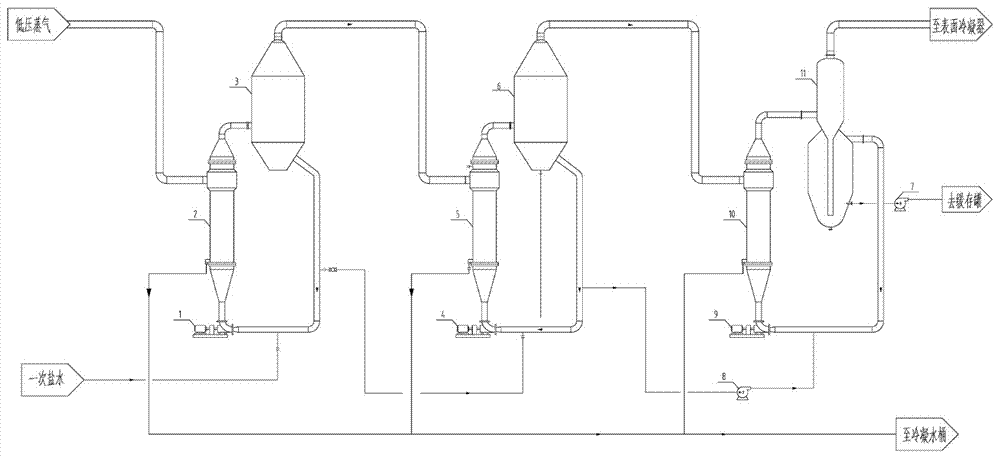

[0059] The potassium chloride solution is transported to the circulation pipeline of the III-effect separation chamber through the feed pump, and after being flashed and concentrated by the III-effect heat exchanger and the III-effect separation chamber, the material is transported to the II-effect crystallizer through the III-effect discharge pump. The circulation pipeline is further flashed and concentrated, and then transported to the circulation pipeline of the I-effect separation chamber through the II-effect transfer pump after the II-effect concentration, through the heat exchange of the I-effect heat exchanger and the high-temperature flash concentration of the I-effect separation chamber, and then passed through the pipeline The pressure difference is transported to the circulation pipeline of the II-effect crystallizer, ...

Embodiment 2

[0061] This embodiment is used to illustrate the food-grade potassium chloride crystal provided by the present invention and its production method.

[0062] The potassium chloride solution is transported to the circulation pipeline of the III-effect separation chamber through the feed pump, and after being flashed and concentrated by the III-effect heat exchanger and the III-effect separation chamber, the material is transported to the II-effect crystallizer through the III-effect discharge pump. The circulation pipeline is further flashed and concentrated, and then transported to the circulation pipeline of the I-effect separation chamber through the II-effect transfer pump after the II-effect concentration, through the heat exchange of the I-effect heat exchanger and the high-temperature flash concentration of the I-effect separation chamber, and then passed through the pipeline The pressure difference is transported to the circulation pipeline of the II-effect crystallizer, ...

Embodiment 3

[0064] This embodiment is used to illustrate the edible potassium chloride crystal provided by the present invention and its production method.

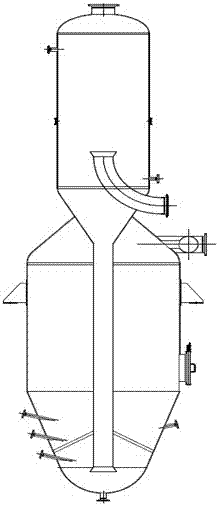

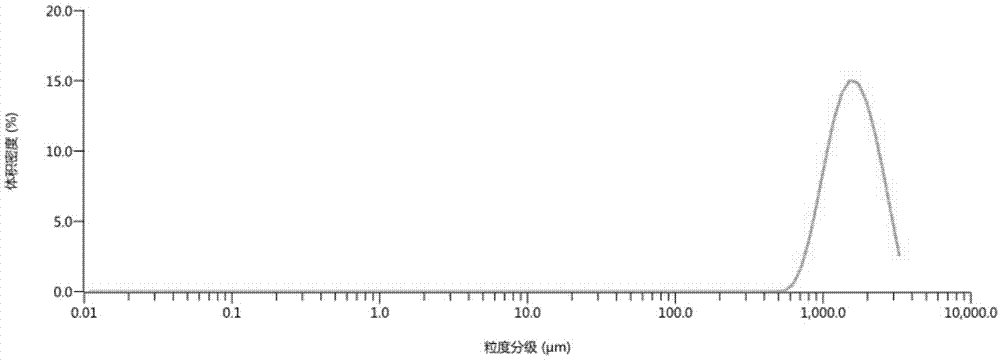

[0065] The potassium chloride solution is transported to the circulation pipeline of the III-effect separation chamber through the feed pump, and after being flashed and concentrated by the III-effect heat exchanger and the III-effect separation chamber, the material is transported to the II-effect separation chamber through the III-effect discharge pump. The circulation pipeline is further flashed and concentrated, and then transported to the circulation pipeline of the I-effect crystallizer through the II-effect transfer pump after the II-effect concentration, and then evaporated and crystallized, and the temperature of the feed liquid is raised to 110 At about ℃, the concentration of potassium chloride is 36% (w / w), the material enters the circulation pipe of the I-effect crystallizer for evaporation and crystallization, the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com