Long-chain dicarboxylic acid refining device

A long-chain dibasic acid and refining device technology, which is applied in the direction of evaporator adjustment/control, separation/purification of carboxylic acid compounds, separation methods, etc., and can solve problems such as difficult crystal forms, poor uniformity, and poor washing effect , to achieve the effect of uniform product particle size, increase product yield, and large product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

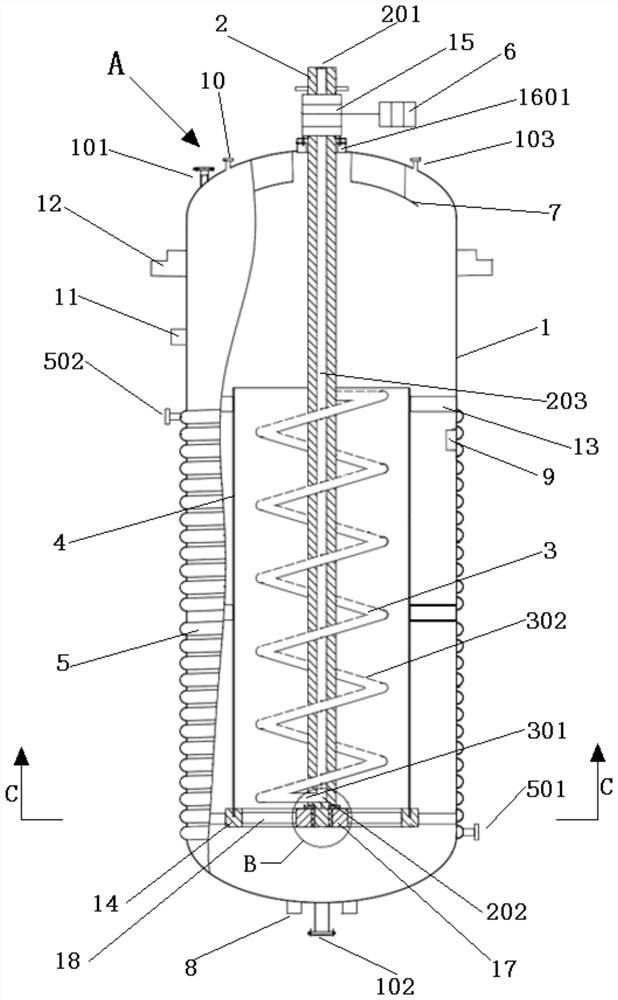

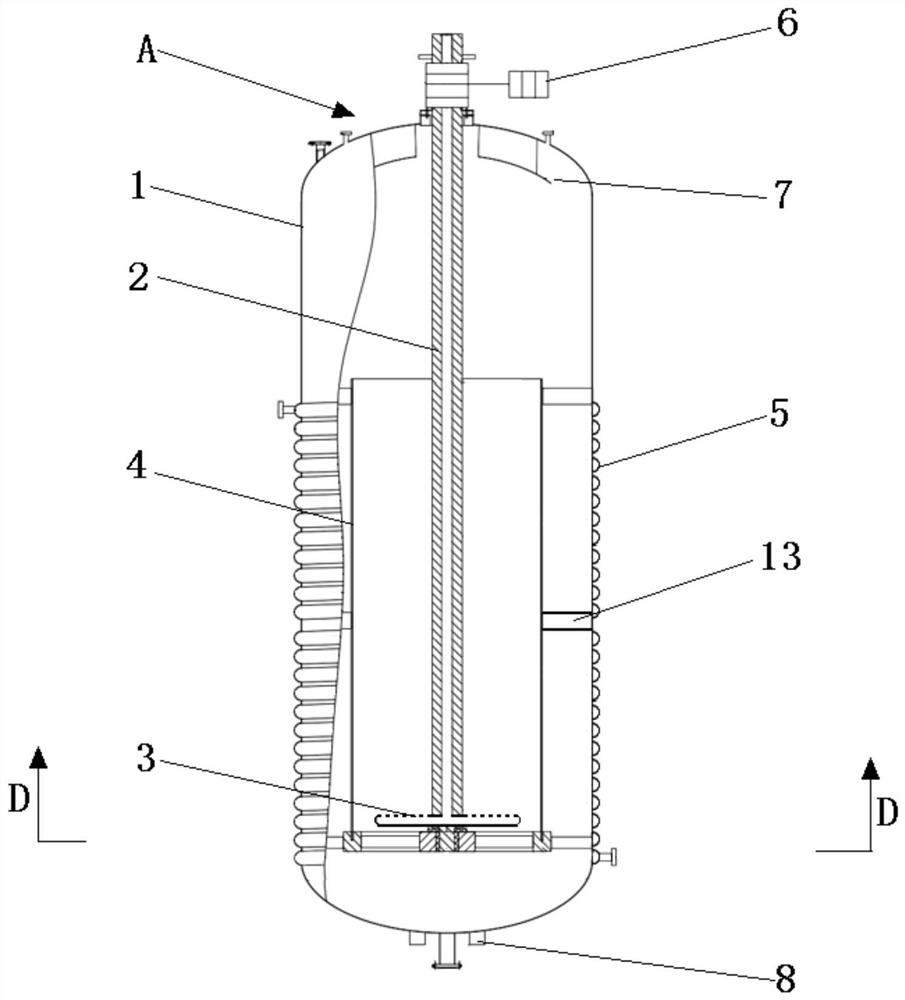

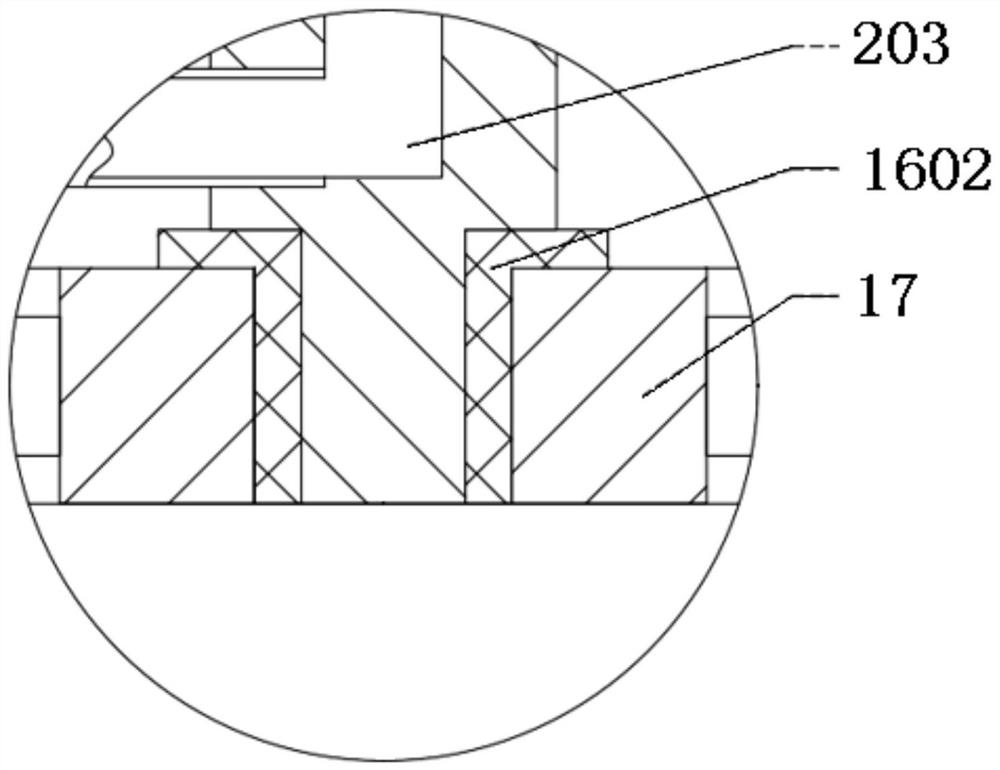

[0058] Such as figure 1 As shown, a long-chain dibasic acid refining device, the long-chain dibasic acid refining device A includes a crystallization / washing kettle 1, a hollow main shaft 2, an air injection pipe 3, a diversion inner cylinder 4, a heat pipe 5, and a driving device 6. Wherein: the hollow main shaft 2, the jet pipe 3, and the diversion inner cylinder 4 are arranged in the crystallization / crystal washing kettle 1. The heat pipe 5 is arranged around the outside of the crystallization / cleaning tank 1 . The upper part or the top of the crystallization / cleaning tank 1 is provided with a feed port 101 and a tail gas port 103 . The lower part or bottom of the crystallization / cleaning tank 1 is provided with a discharge port 102 . The hollow main shaft 2 extends into the flow guiding inner cylinder 4 . The air jet pipe 3 is located in the flow guiding inner cylinder 4 . The hollow main shaft 2 is provided with an air inlet 201 and an air outlet 202 . The jet pipe ...

Embodiment 2

[0060] Repeat Example 1, except that the crystallization / washing tank 1 is also provided with an air outlet baffle 7. The gas outlet baffle 7 is arranged in the crystallization / washing tank 1 and is located below the tail gas port 103 .

Embodiment 3

[0062] Example 1 was repeated, except that the crystallization / washing tank 1 also included a wall vibrator 8 . The wall vibrator 8 is arranged on the inner wall or the outer wall of the crystallization / cleaning tank 1 , and is located at the position of the discharge port 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com