A kind of production method of anticoagulant drug intermediate

A tungsten disulfide, modified technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. The particle size is uniform, the particle size is large, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

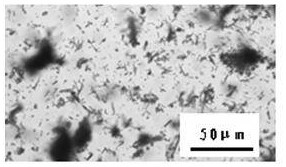

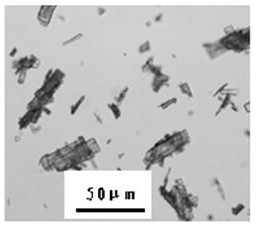

Image

Examples

Embodiment 1

[0042] Preparation of tungsten disulfide modified Pt / Ni bimetallic highly dispersed nanocatalyst:

[0043] 1) Add different molar amounts of platinum acetylacetonate (Pt(acac) 2 ), nickel acetylacetonate (Ni(acac) 2 ) and tungsten disulfide (WS 2 ) dispersed in a mixed solution of oleylamine and tetrahydrofuran (calculated by volume: oleylamine / tetrahydrofuran=90:10) and heated to 100-120°C and stirred for 0.5h to obtain a brown-yellow mixed solution; each gram of the composition (Pt(acac) 2 、Ni(acac) 2 and WS 2 Three gross weights and) the amount that adds the mixed solution of oleylamine and tetrahydrofuran is 8ml;

[0044] 2) Transfer the brown-yellow mixed liquid to the high-pressure reactor, feed nitrogen, replace the air in the high-pressure reactor with nitrogen three times, and then replace the nitrogen in the high-pressure reactor with hydrogen for three times, and raise the temperature to 200±20°C after the replacement , pass in hydrogen and react for 1-2h under...

Embodiment 2

[0050] Catalytic performance evaluation is carried out to the catalyst of the different proportioning ratio that above-mentioned embodiment prepares, and method is as follows: Add 3-[(4-methylamino-3-nitro-benzamide group) (pyridine-2- base)] ethyl propionate (3.72g, 10mmol, HPLC purity is 98.9%), anhydrous methanol 50ml, the different catalysts (0.372g, 10wt%) that embodiment 1 prepares, adopt the air in the nitrogen replacement kettle, then adopt hydrogen Replace the nitrogen in the kettle, feed hydrogen, and react at 45°C under a hydrogen pressure of 1MPa. When the substrate is no longer converted and the product is no longer increased by HPLC detection, the reaction is stopped to calculate the conversion rate of the substrate and the selectivity of the target product. Statistics The results are shown in Table 2:

[0051] Catalytic effect of different catalysts in table 2

[0052] sequence catalyst Reaction time / h Conversion rate / % selectivity / % 1 C...

Embodiment 3

[0055] After identifying the Cat-Pt 80 / Ni 10 / W 5 When being a catalyst, the influence of different solvents, different hydrogen pressures, and different catalyst consumptions (based on the weight of the substrate) on the reaction was investigated, and the preparation process is as follows:

[0056] Add ethyl 3-[(4-methylamino-3-nitro-benzamido)(pyridin-2-yl)]propionate (3.72g, 10mmol, HPLC purity 98.9%) to the high-pressure hydrogenation reactor , solvent 50ml, Cat-Pt 80 / Ni 10 / W 5 (0.372g, 10wt%), adopt nitrogen to replace the air in the still, then adopt hydrogen to replace the nitrogen in the still, pass into hydrogen and react at 45°C under different hydrogen pressures, HPLC detects that when the substrate is no longer converted and the product is no longer increased , stop the reaction to calculate the substrate conversion rate and the selectivity of the target product, and the statistical results are as shown in Table 3:

[0057] Table 3 The influence of differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com