Preparation method of zinc oxide/titanium dioxide composite nanomaterial

A technology of composite nanomaterials and titanium dioxide, which is applied in the field of preparation of zinc oxide/titanium dioxide composite nanomaterials, can solve the problems of high equipment requirements and achieve the effects of good dispersion, low energy consumption and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of zinc oxide / titanium dioxide composite nanomaterial of the present invention comprises the following steps:

[0025] Step 1, take P25 type titanium dioxide powder according to the concentration of 0.274g / L, disperse it in deionized water, use magnetic force or electric stirring to mix evenly; Add hexamethylenetetramine (the molar ratio of soluble zinc salt to hexamethylenetetramine is between 1:0.5 and 2) into the solution at a concentration of 25mmol / L, and mix evenly to obtain a dispersed solution;

[0026] Step 2, heating the dispersion solution in step 1 while stirring, allowing it to react at a temperature of 95° C. for 20 minutes to complete the growth process;

[0027] In step 3, the precipitate after the reaction in step 2 is filtered, washed and dried to obtain the final product.

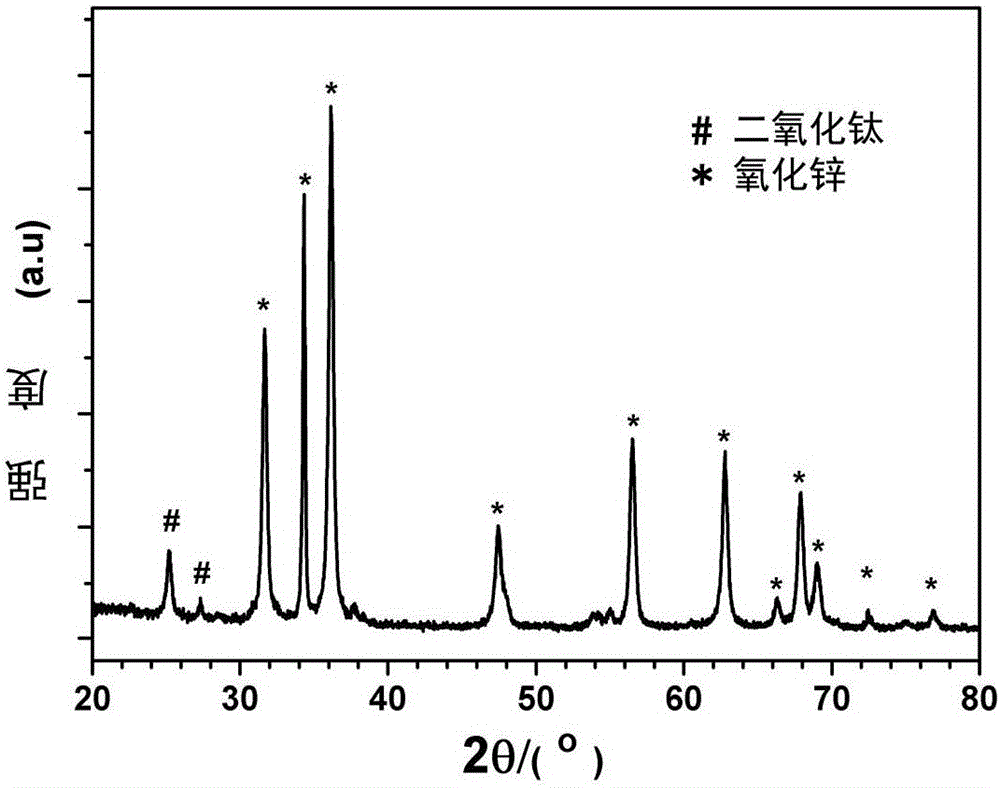

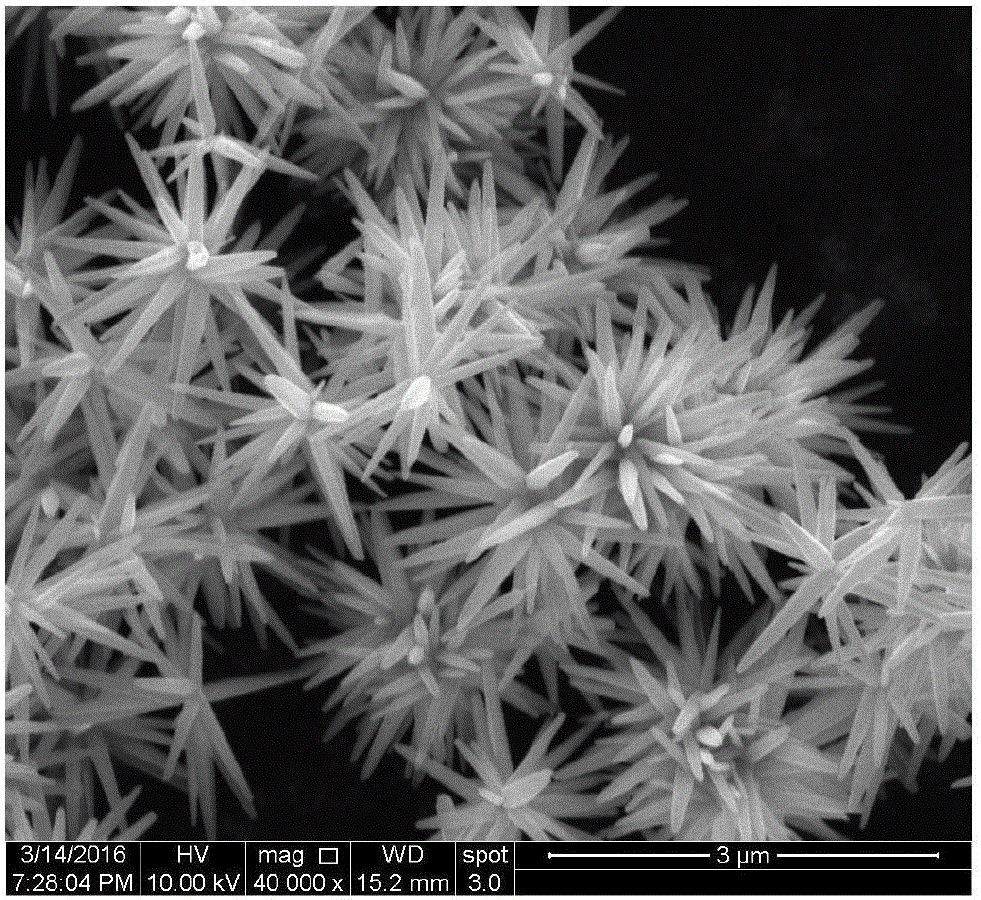

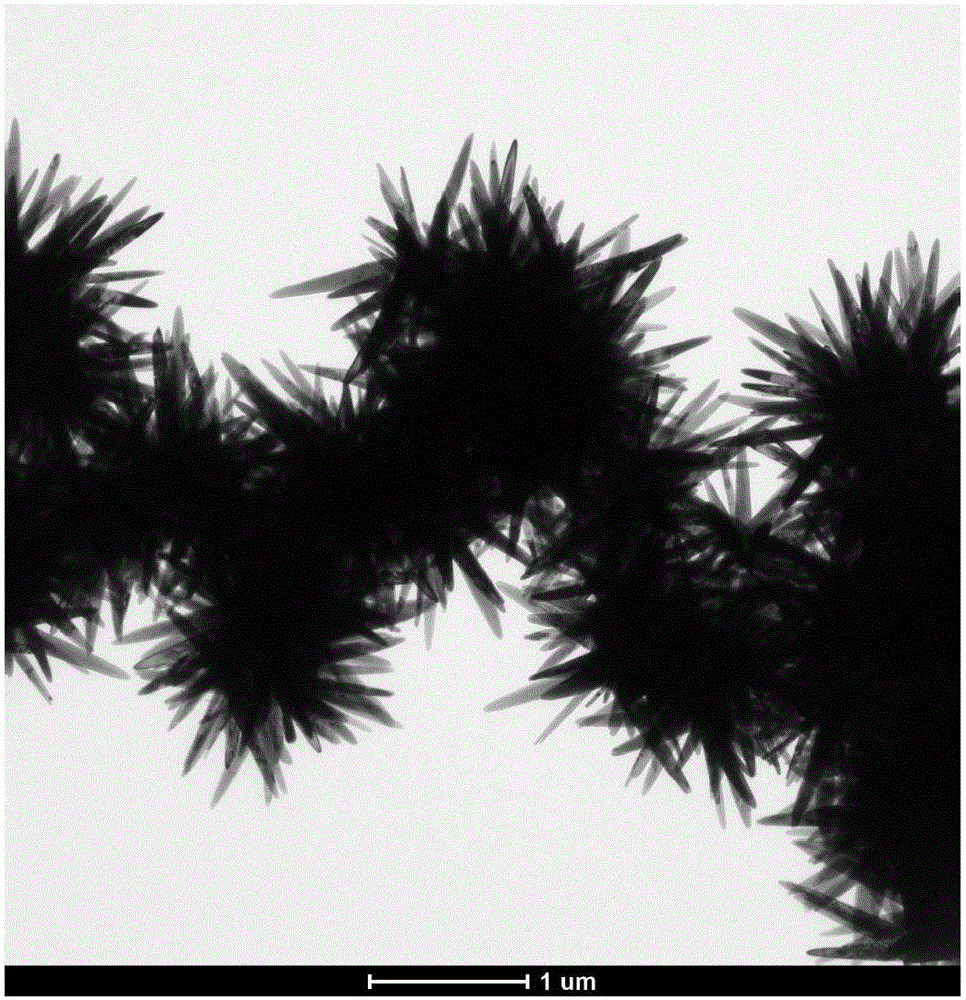

[0028] In the zinc oxide / titanium dioxide composite nanomaterial prepared in Example 1, the mass percentage of titanium dioxide is 14%. figure 1 For the X-...

Embodiment 2

[0030] The preparation method of zinc oxide / titanium dioxide composite nanomaterial of the present invention comprises the following steps:

[0031] Step 1, take the P25 type titanium dioxide powder by weighing 0.274g / L according to the concentration, disperse it in deionized water, use magnetic force or electric stirring to mix evenly; / L Add hexamethylenetetramine to the solution, and mix evenly to obtain a dispersed solution;

[0032] Step 2, heating the dispersion solution in step 1 while stirring, making it react at a temperature of 80°C for 40 minutes to complete the growth process;

[0033] In step 3, the precipitate after the reaction in step 2 is filtered, washed and dried to obtain the final product.

[0034] In the zinc oxide / titanium dioxide composite nanomaterial prepared in Example 2, the mass percentage of titanium dioxide is 20%. The results show that the morphology and structure of the product are basically the same as those of Example 1 except that the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com