Film on surface of car-specification part and development method of film

A surface film and gauge-level technology, which is applied to the surface coating liquid device, pre-treatment surface, coating, etc., can solve the problems that the film layer cannot meet the high-gloss effect and the laser engraving requirements of the car-level requirements at the same time, and achieve The effect of thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention, but not to limit the scope of application of the present invention.

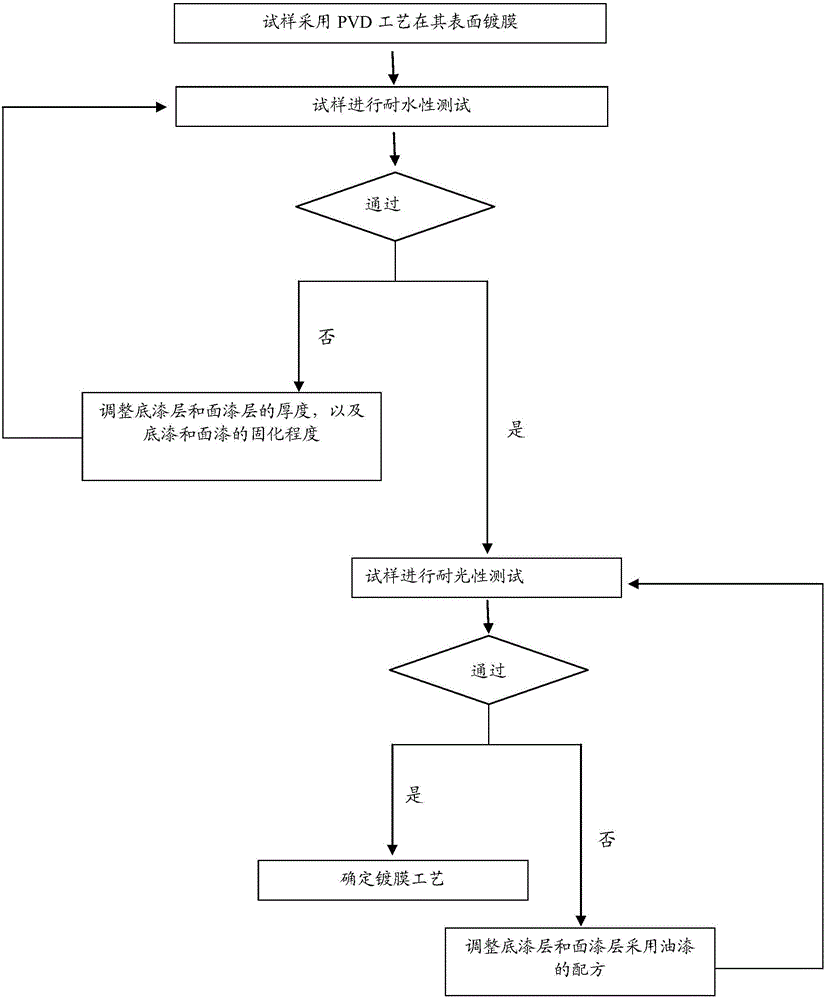

[0030] Please refer to figure 1 , a method for developing a vehicle-grade automotive switch button surface film, the process is as follows:

[0031] The automobile switch button adopts PVD process to coat the surface of the automobile switch button to form a film layer. The PVD process flow is as follows: first, trim the surface of the automobile switch button, and then spray a layer of primer on the surface of the automobile switch button by painting, Drying and curing to form a primer layer, using PVD technology to coat the primer layer, the specific operations are as follows: place the vehicle switch button in the vacuum chamber of the magnetron sputtering device, pass argon gas, and start the magnetron spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com