Coating for circuit of LDS shell

A coating and circuit technology, applied in the field of coatings for LDS chassis circuits, can solve the problems of primers failing to meet performance requirements, and achieve the effects of improving antenna circuit quality, product yield, and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

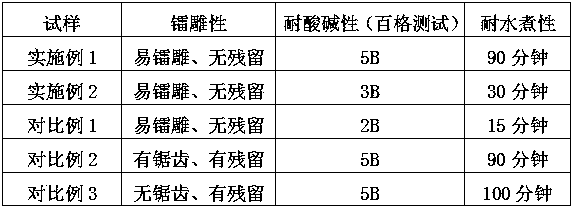

Examples

Embodiment Construction

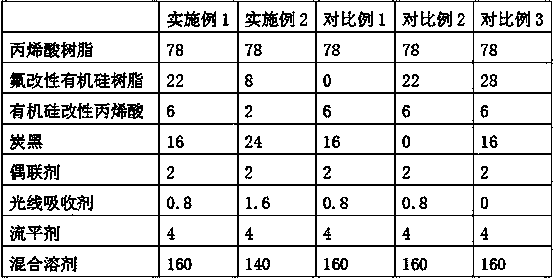

[0016] Embodiments of the present invention are described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0017] In some typical embodiments, in terms of parts by mass, the formula composition of the coating for LDS casing circuit can be:

[0018] Acrylic resin 10-60 parts

[0019] Fluorine modified silicone resin 5-20 parts

[0020] Silicone modified acrylic compatibilizer 1-10 parts

[0021] Carbon black 3-20 parts

[0022] 0.3-10 parts of coupling agent

[0023] 0.1-8 parts of light absorbing agent

[0024] Leveling agent 0.1-3 parts

[0025] Solvent 20-120 parts

[0026] Among them, the fluorine-modified silicone resin can significantly improve the acid and alkali resistance and water boiling resistance of the coating, and the use of carbon black and light absorbers together can improve the laser engraving of the coating, making the coating easy to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com