Construction method and installation accuracy control method of nut column systems of high-lift rack climbing type ship lift

A construction method and nut column technology, which is applied in the vertical lifting of ship machinery, ship lifting devices, buildings, etc., can solve the problems of large size, heavy weight and complex structure of a single piece of nut column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

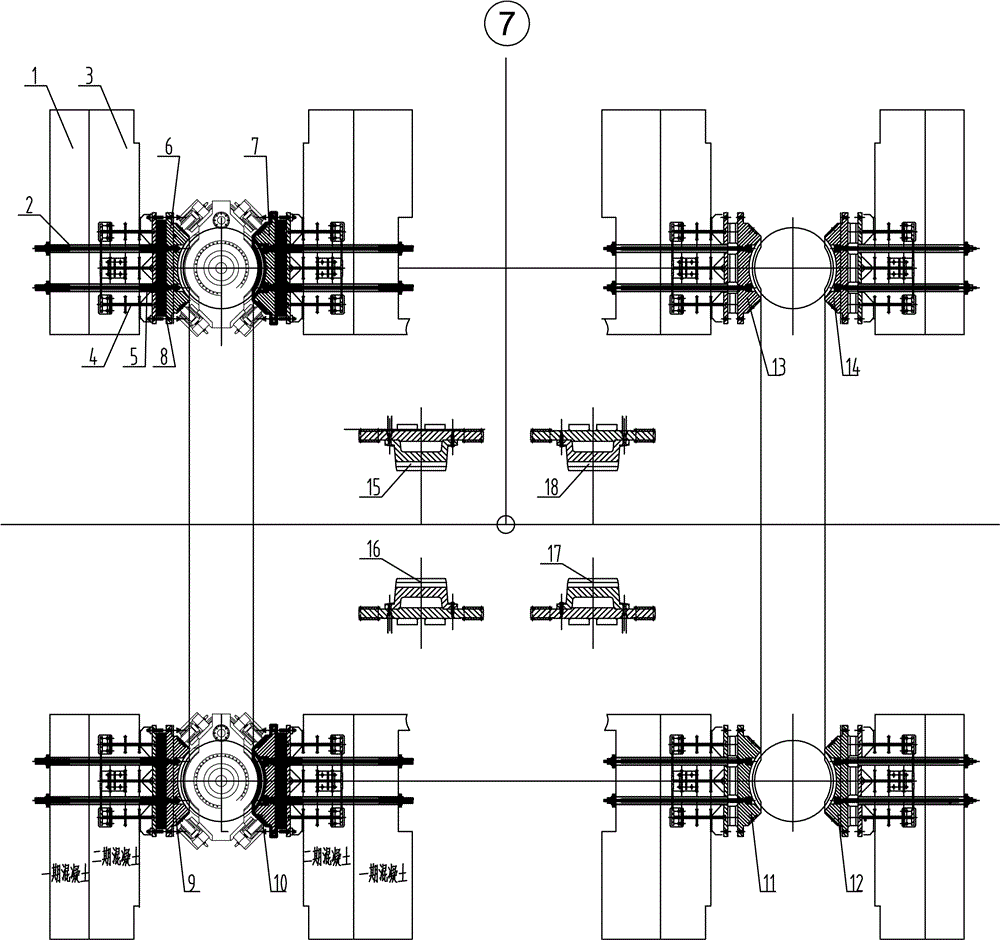

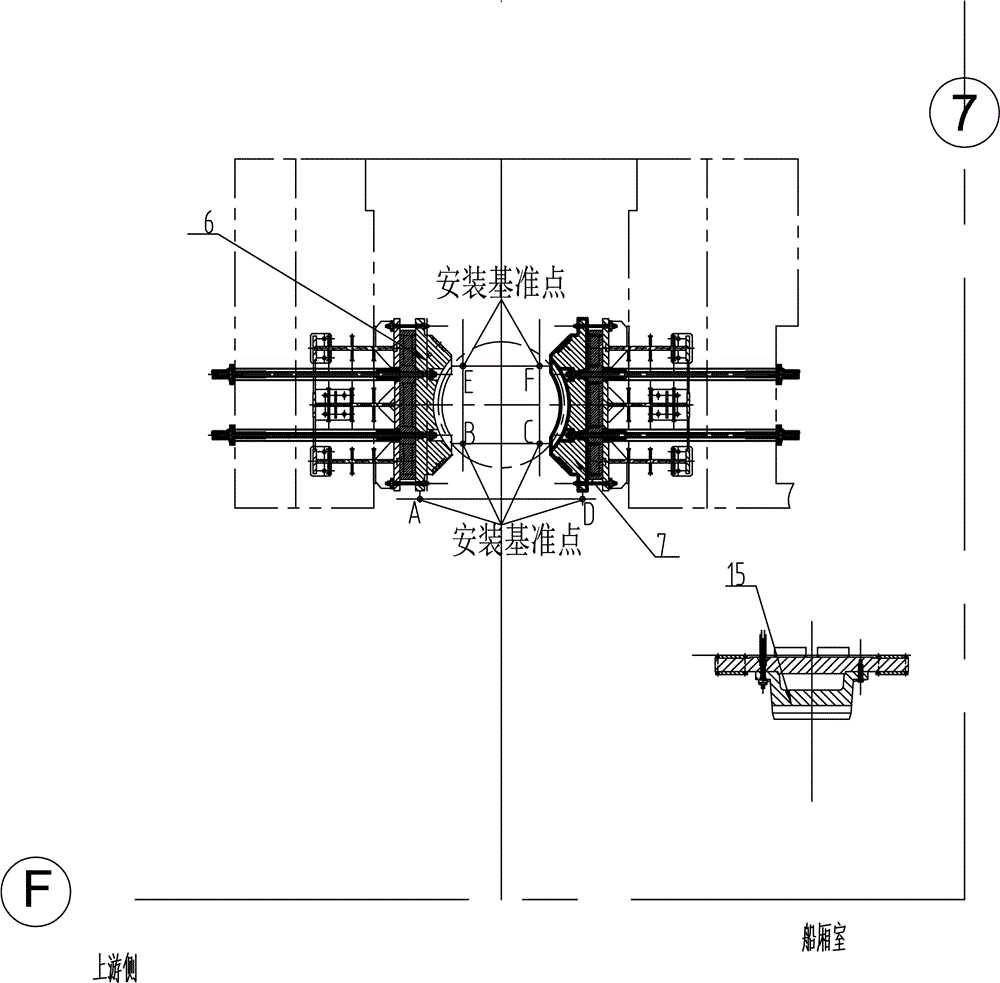

[0063] see figure 1, is the top view of the overall installation and arrangement of four sets of nut columns of the ship lift of the present invention, firstly carry out the construction pouring of the first-stage concrete 1, then carry out the pouring of the second-stage concrete 3 and the second-stage embedded parts 4, and finally carry out the No. 1 left nut column 6 , the installation of the No. 1 right nut column 7, and the prestressed steel bar 5 is used to tension the nut column, and the gap between the No. 1 left nut column 6, the No. 1 right nut column 7 and the second-stage concrete 3 is PAGELV1 / 50 mortar 8 for filling and connection. The ship lift includes four sets of nut column systems. Each set of nut column systems needs to meet the corresponding position accuracy control requirements, so as to ensure the normal and reliable operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com