Construction method and installation accuracy control method of rack system of high-lift gear climbing ship lift

A construction method and high-lift technology, which is applied in the vertical lifting of ship machinery, ship lifting devices, buildings, etc., can solve the problems of large single-piece rack size, high installation height, and heavy weight, so as to ensure installation quality and installation accuracy , Guarantee concentricity, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

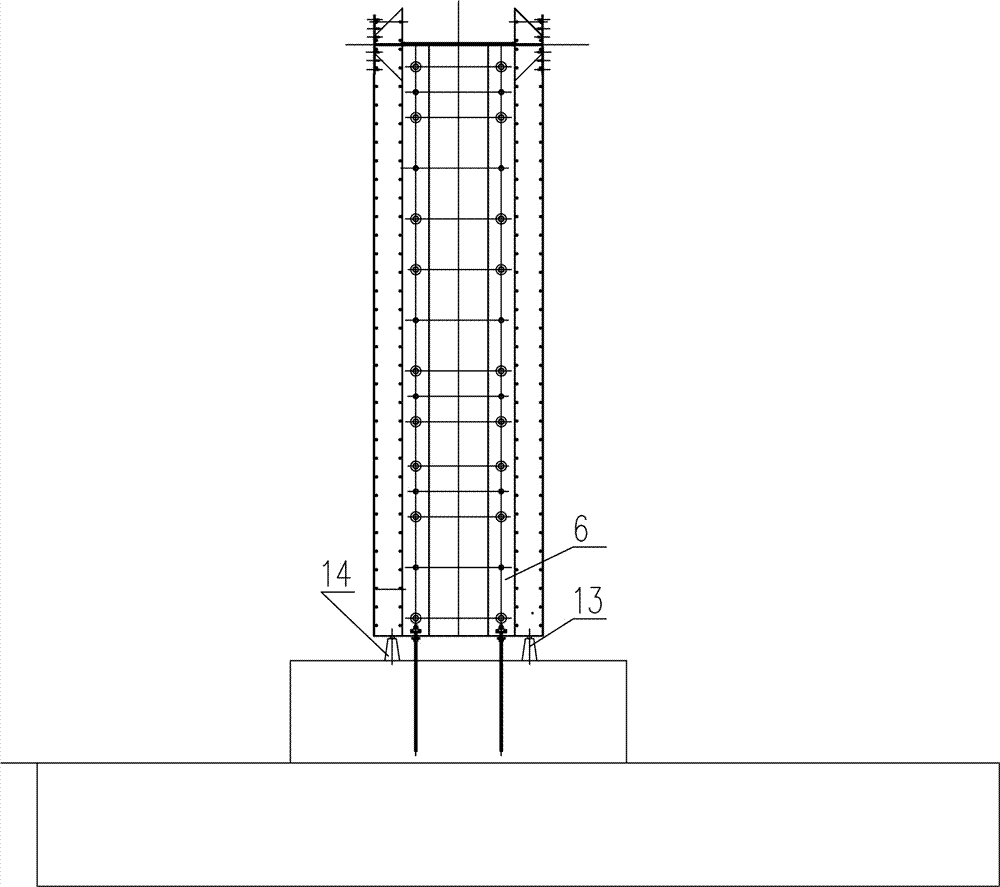

[0064] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

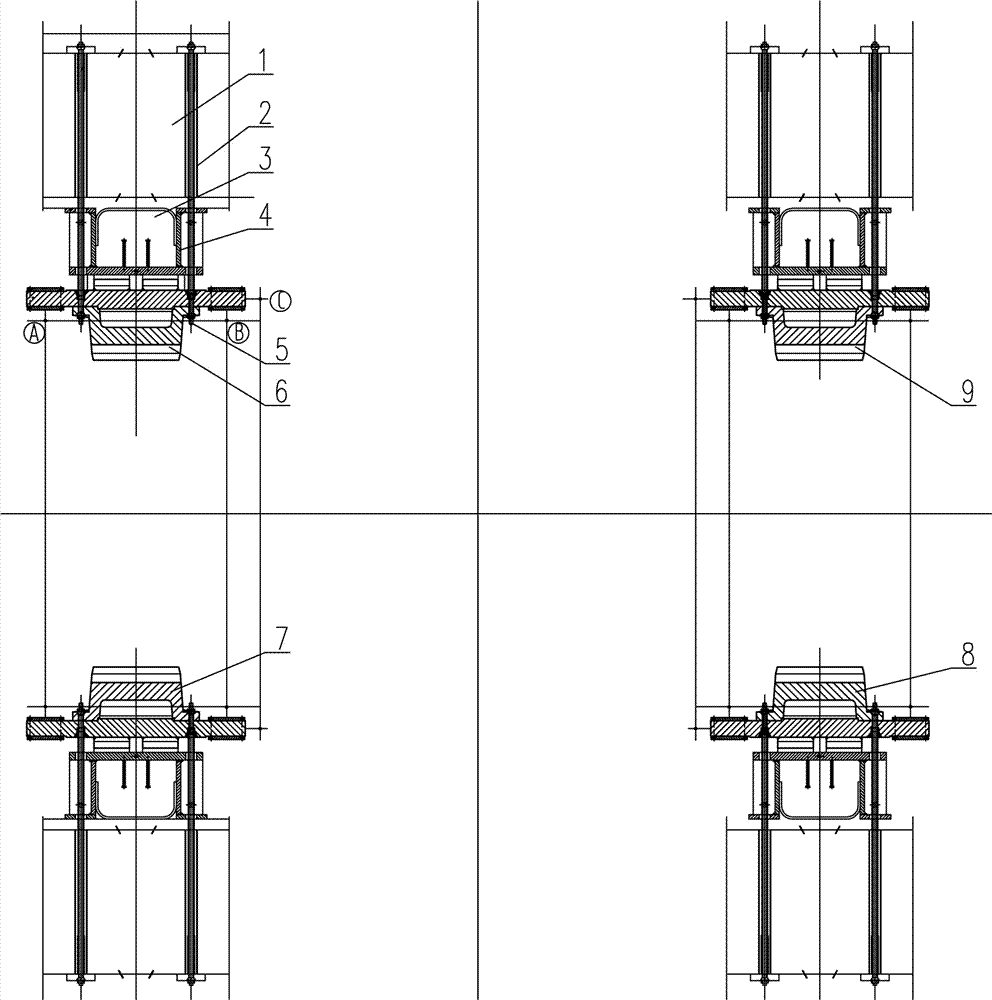

[0065] see figure 1 , is the top view of the overall installation and layout of the four sets of racks of the ship lift of the present invention. First, the construction of the first-stage concrete 1 is poured, and then the second-stage concrete 3 and the second-stage embedded parts 4 are poured, and finally the No. 1 rack 6 is poured. Install, and use prestressed steel bars 5 to tension and fix the rack. The ship lift includes four sets of rack systems. Each rack system needs to meet the corresponding position accuracy control requirements, so as to ensure the normal and reliable operation of the ship lift. .

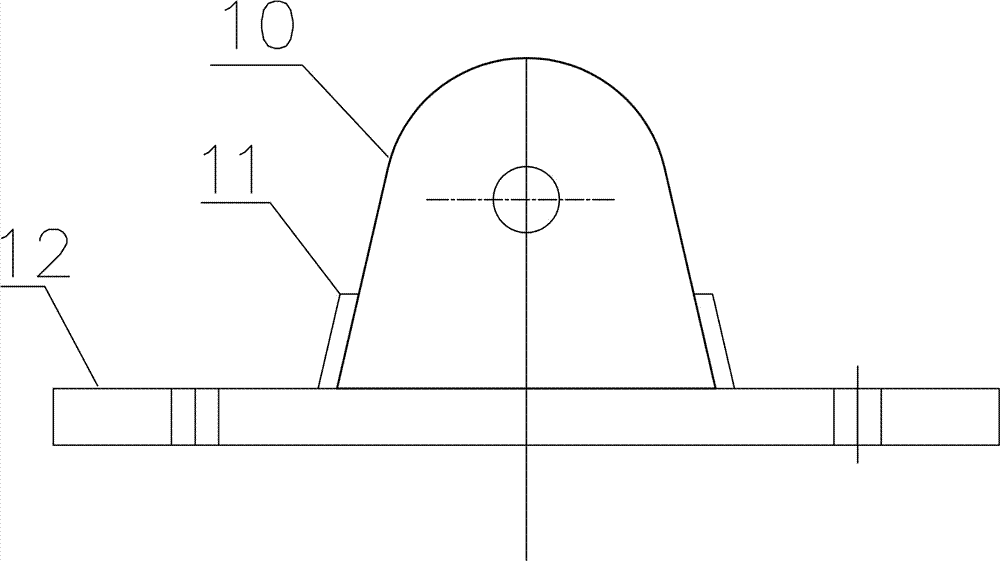

[0066] see figure 2 , is the lug used in the hoisting process of the ship lift rack of the present invention, the lug can be connected with the rack, so as to facilitate the hoisting of the rack, wherein the lug plate 10 is installed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com