Lifting device for building-attached lifting scaffold

A technology of attaching lifting and scaffolding, which is applied in the direction of construction, scaffolding supported by house structure, building structure, etc., can solve the problems of hidden safety hazards, equipment loss, equipment failure, etc., to reduce labor intensity of workers, reduce equipment failure rate, The effect of reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical characteristics of the present invention will be described in detail below in conjunction with the accompanying drawings.

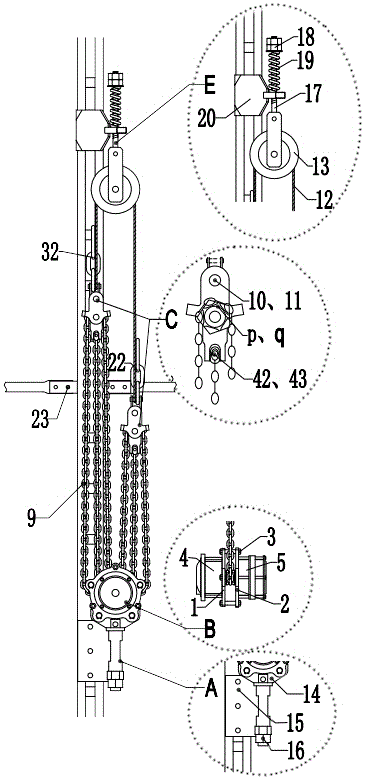

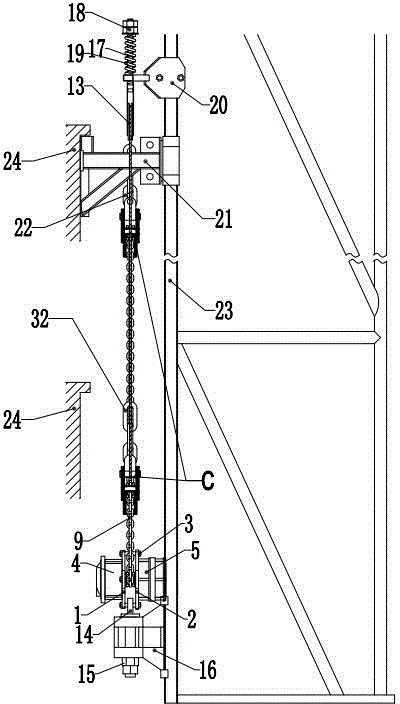

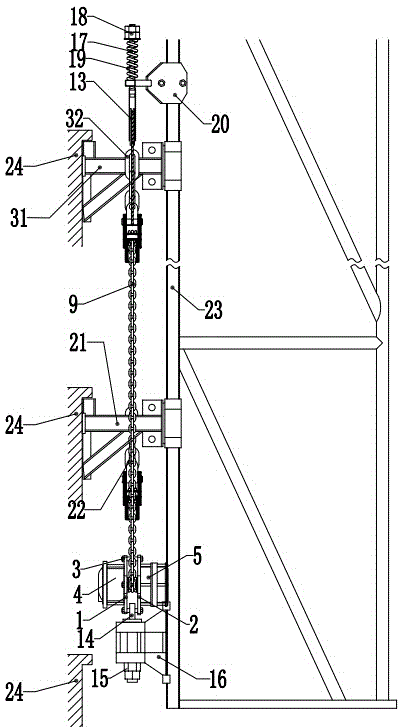

[0026] like figure 1 Shown: the lifting device according to the present invention, including base (A), lifting main engine (B), double power pulley block (C), hinge (22), hinge (32), tensioning mechanism (E), chain (9 ), the lifting device has two sets of double-force pulley blocks (C), and the two sets of double-force pulley blocks (C) are respectively connected to the hinge (22) and the hinge (32). During construction, the base (A) is fixed on the main frame of the attached lifting scaffold (23) The lower part, the lifting main unit (B) is installed on the base (A), the chain (9) is wound on the double force pulley block (C) and the lifting main unit (B) to form two sets of double force pulley structures, and the hinge (22) Connect with the attached wall support (21), the two ends of the steel wire rope (12) in the tensioning mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com