A kind of original wooden door structure and its manufacturing method

A wood door and wood chip technology, applied in the field of log door structure and its production, can solve the problems of easy deformation of fast-growing small-diameter sawn timber, inability to use to manufacture solid wood doors, slow drying speed of small-diameter logs, etc. , Reduce the effect of drying and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

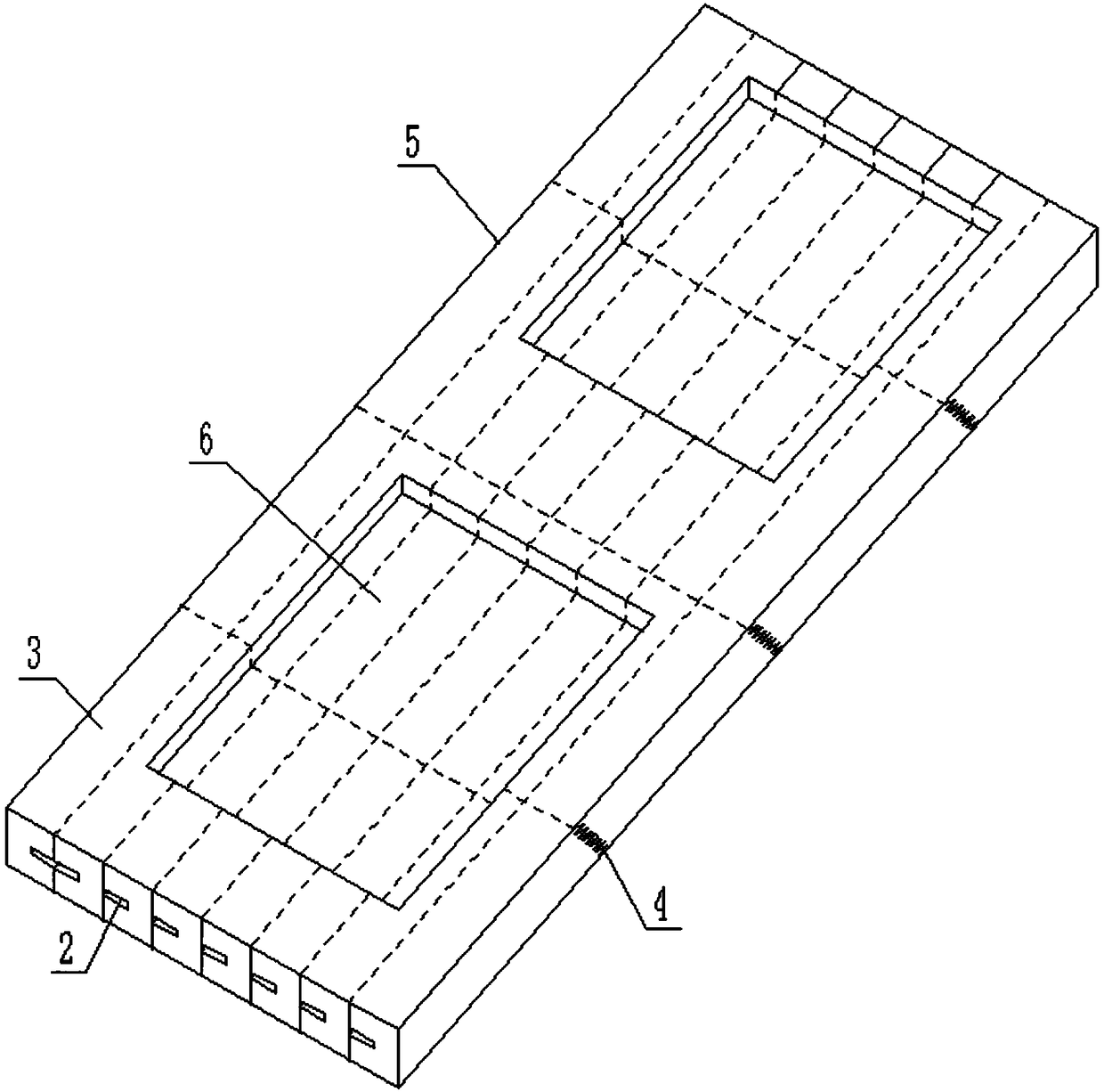

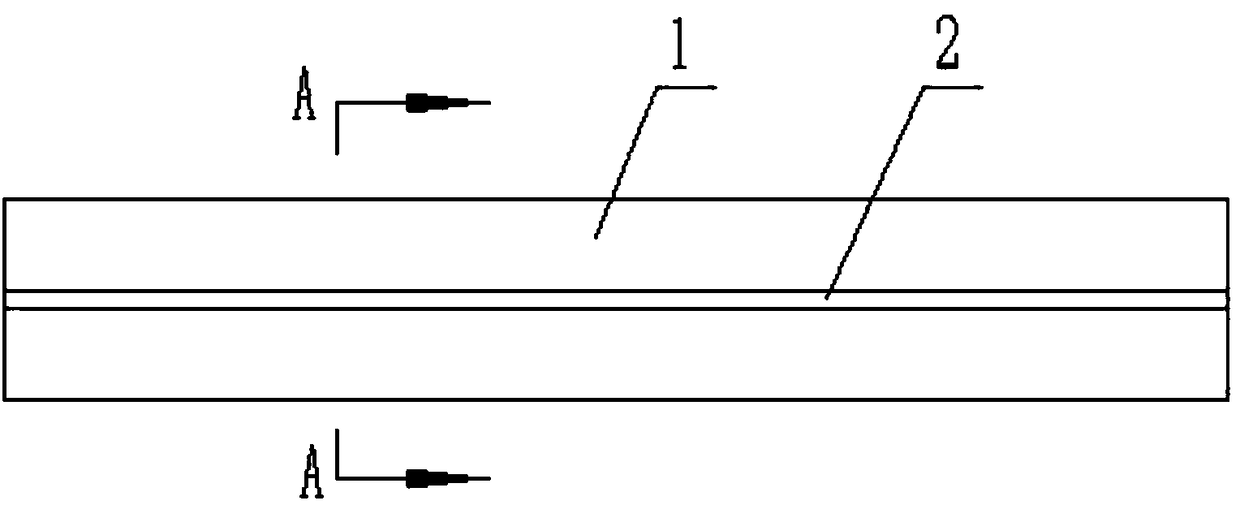

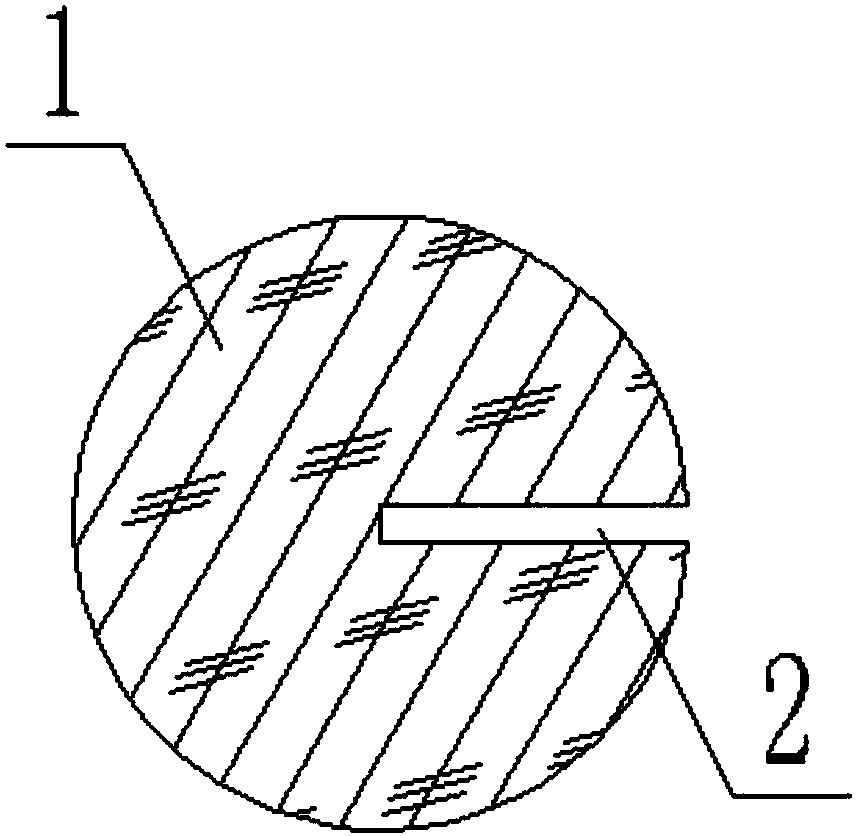

[0051]Take a log that is straight as a whole and has a diameter of 55 ± 5 mm, and cut the log into a round wood 1 of 400 ± 2 mm; saw a drying tank 2 parallel to the central axis of the round wood 1 on the outer wall of the round wood 1, and the width of the drying tank 2 is 4 mm. The depth is equal to the radius of the round wood 1, and the length of the drying tank 2 is equal to the length of the round wood 1; the round wood is placed in the drying equipment with a dry ball and a wet ball inside for drying treatment, and the water content of the round wood 1 after drying is ≤15 %, the specific steps of the drying process are: at the stage of the moisture content of round wood 1 >55%, keep the dry bulb temperature in the drying equipment at 40°C, and the wet bulb temperature at 38°C, and dry for 120 hours; at the stage of the moisture content of 55%-40%, keep it dry The dry bulb temperature in the equipment is 47°C, the wet bulb temperature is 44°C, dry for 72 hours; the moistu...

Embodiment 2

[0059] Take a log that is straight as a whole and has a diameter of 40-70mm, cut the log into a round wood 1 of 300-550mm; saw a drying tank 2 parallel to the central axis of the round wood 1 on the outer wall of the round wood 1, and dry the tank 2 The width is 3-5mm, the depth is equal to the radius of the round material 1, the length of the drying tank 2 is equal to the length of the round material 1; the round material is placed in the drying equipment with a dry ball and a wet ball inside for drying treatment, and the round material 1 is dried after drying. The moisture content of the material is ≤15%, and the specific steps of the drying process are: in the stage of the moisture content of round wood 1>55%, keep the dry bulb temperature in the drying equipment at 40°C, the wet bulb temperature at 38°C, and dry for 80 hours; the moisture content is 55%-40 % stage, keep the dry bulb temperature in the drying equipment at 50°C, wet bulb temperature at 40°C, and dry for 40 ho...

Embodiment 3

[0067] Take a log that is straight as a whole and has a diameter of 40-70mm, cut the log into a round wood 1 of 300-550mm; saw a drying tank 2 parallel to the central axis of the round wood 1 on the outer wall of the round wood 1, and dry the tank 2 The width is 3-5mm, the depth is equal to the radius of the round material 1, the length of the drying tank 2 is equal to the length of the round material 1; the round material is placed in the drying equipment with a dry ball and a wet ball inside for drying treatment, and the round material 1 is dried after drying. The moisture content of the material is ≤15%, and the specific steps of the drying process are as follows: at the stage of the moisture content of round wood 1>55%, keep the dry bulb temperature in the drying equipment at 40°C, the wet bulb temperature at 38°C, and dry for 72 hours; the moisture content is 55%-40 % stage, keep the dry bulb temperature in the drying equipment at 45°C, wet bulb temperature at 44°C, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com