Heavy-duty gas turbine shell

A gas turbine and cover technology, which is applied in the direction of gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of flammable gas leakage, thermal components burnt, heavy gas turbine noise, etc., to reduce explosion losses, avoid danger, The effect of quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

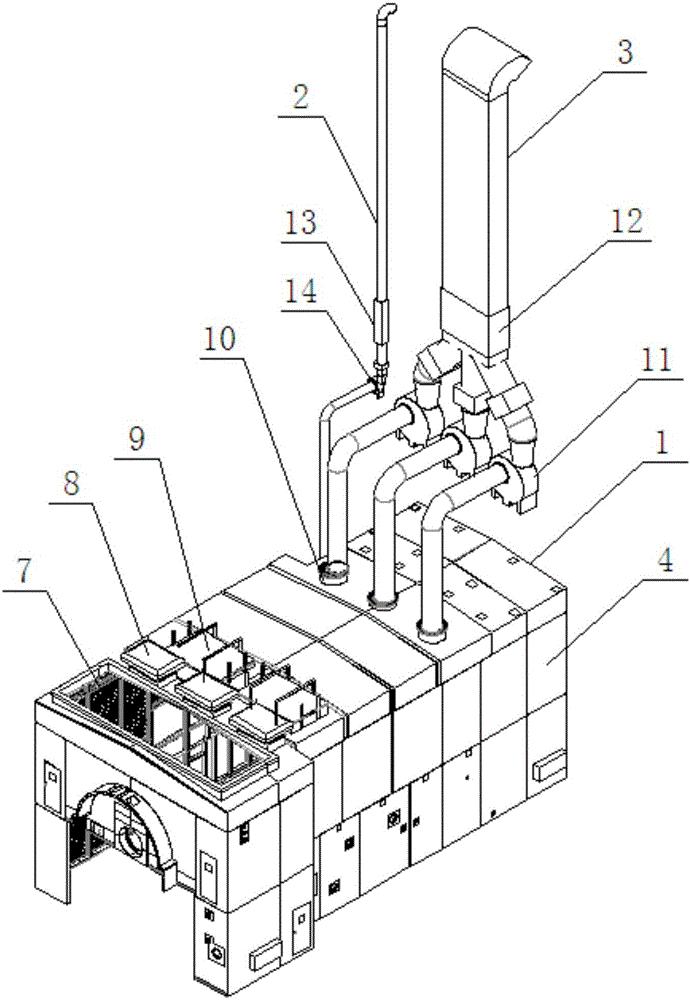

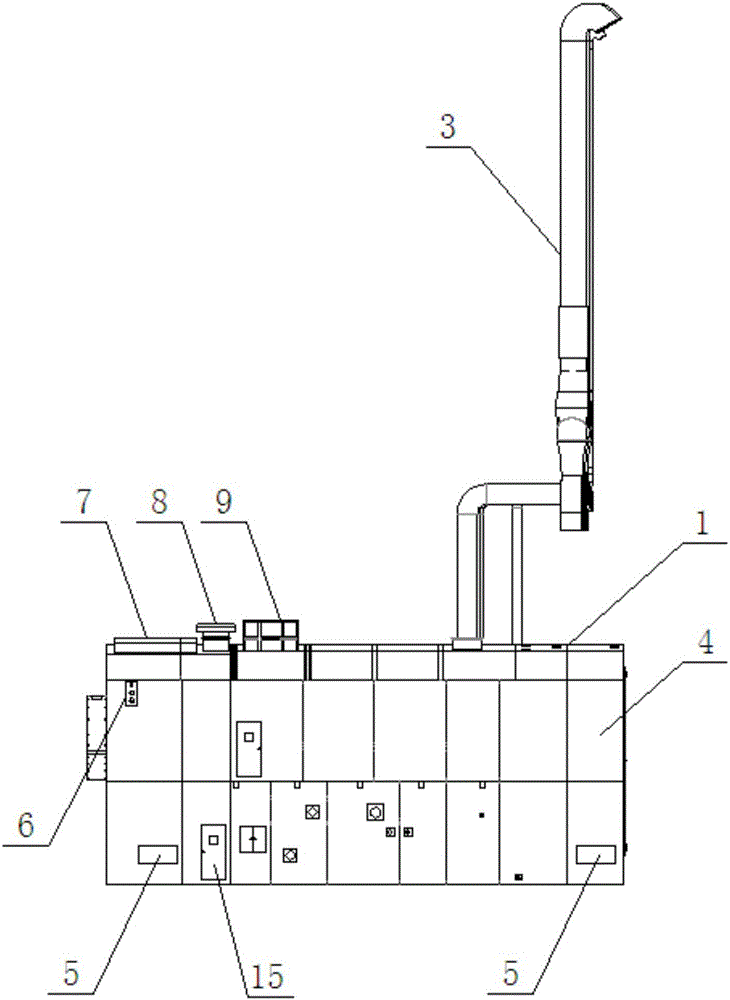

[0024] A heavy-duty gas turbine casing, including a casing body 1, an FG pipe frame exhaust pipe 2 and a gas turbine casing exhaust pipe 3, the casing body 1 is assembled from several casing wall panels 4, the casing The side wall of the body 1 is provided with a fire damper 5 and a CO 2 The fire-fighting pipeline interface 6, the top wall of the casing body 1 is provided with a gas inlet chamber 7, a ventilation cover 8, an explosion-proof cover plate 9 and a ventilation pipeline interface 10, and the exhaust pipe 3 of the gas turbine casing passes through the fan 11 and The ventilation pipe interface 10 is connected, the exhaust pipe 3 of the gas turbine casing is provided with a muffler I12, and the exhaust pipe 2 of the FG pipe frame is provided with a silencer II13.

[0025] Fire damper 5 and ventilation cover 8 promote air circulation, and fan 11 is connected to forced heat dissipation and forced ventilation, so that the casing can quickly discharge a large amount of hea...

Embodiment 2

[0027] In this embodiment, on the basis of Embodiment 1, the housing body 1 is assembled from upper, middle and lower layers of housing wall panels 4, and the upper layer of housing wall panels 4 of the housing body 1 is the housing body 1, the middle and lower layers of the casing wall 4 of the casing body 1 are the side walls of the casing body 1, and the lower casing wall 4 of the casing body 1 is fixedly connected to the ground; The outer side of the casing wall plate 4 is a steel plate, the inner side is a stainless steel orifice plate, and the middle is filled with sound-absorbing cotton; the casing wall panels 4 are connected by bolts; the casing body has a modular design and can be quickly disassembled.

Embodiment 3

[0029] In this embodiment, on the basis of Embodiment 1, the exhaust pipe 2 of the FG pipe frame is provided with a non-return air door 14 to prevent the gas inside the pipe from flowing backward; the side wall of the casing body 1 is provided with an inspection door 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com