Shock Resistant Clutch

A clutch and anti-shock technology, which is applied in clutches, friction clutches, mechanically driven clutches, etc., can solve problems such as high noise in clutch operation, influence on transmission accuracy, large vibration and impact, etc., so as to alleviate impact wear, ensure transmission stability, and guarantee The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

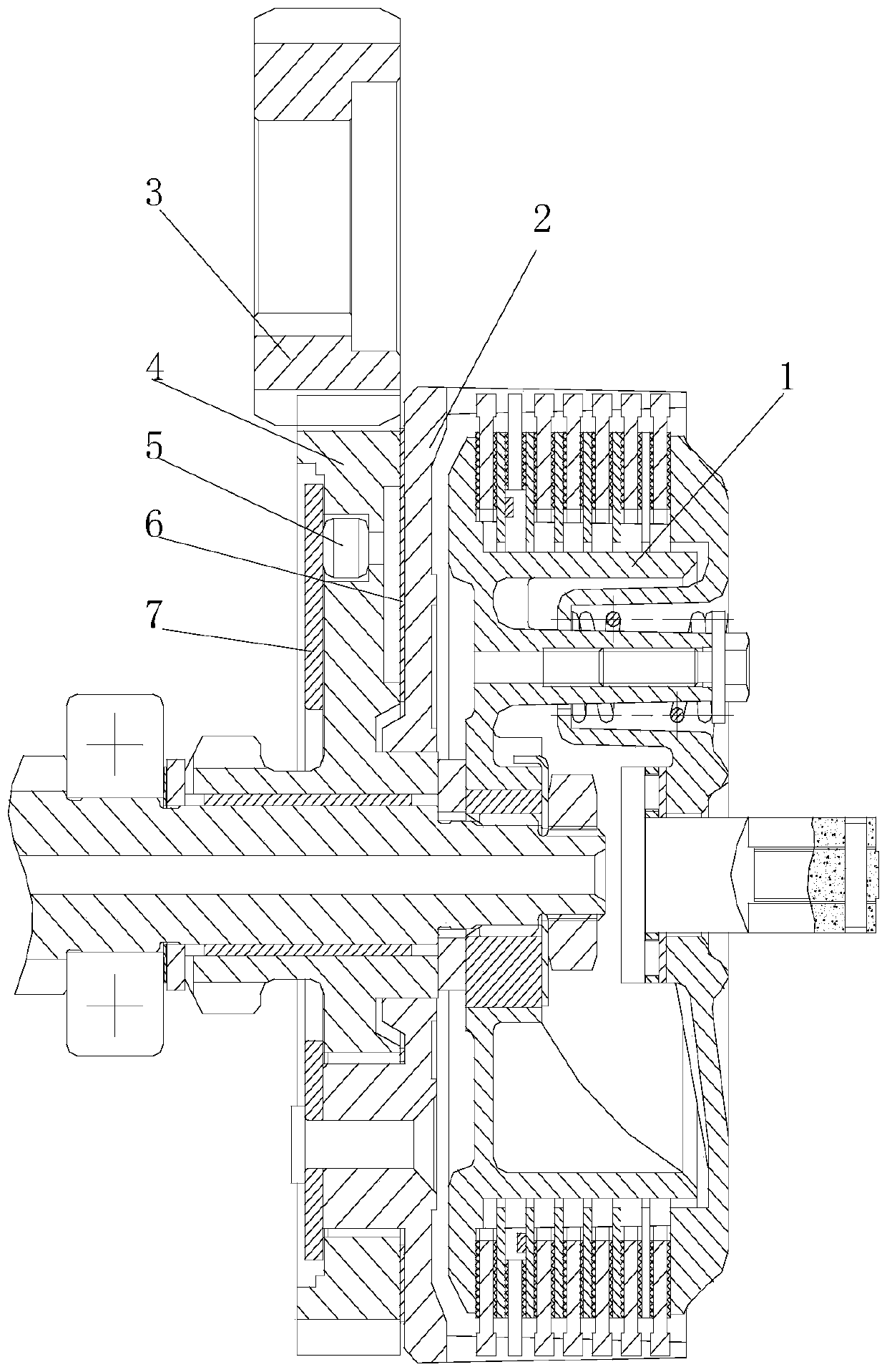

[0018] figure 1 It is a schematic diagram of the structure of the present invention. As shown in the figure, an anti-impact clutch provided by the present invention includes a driving member 2, a driven member 1 and a power input member 4, and also includes a pressing member 7, the pressing member 7 The power input part 4 is press-fitted and installed on the driving part 2 through the shock absorber 5; the driving part 2 generally refers to the clutch cover, of course, it can be different according to the needs of the structure; the driven part 1 is the part that outputs the power through The transmission of the driving friction plate and the driven friction plate belongs to the prior art and will not be repeated here; as shown in the figure, the power input member 4 is generally a power input driven gear, and the power input driving gear 3 is matched with it; The engaging part 7 is connected to the driving part from the axial direction, and presses the power input part between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com