Grooved annular structure sensor based on microstrip line excitation

A microstrip line and sensor technology, applied in the fields of microwave measurement, biochemical detection, and sensor, can solve the problem that broadband measurement or sensing cannot be realized, and achieve the effect of broadband high-sensitivity sensing and high spatial resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings and preferred embodiments.

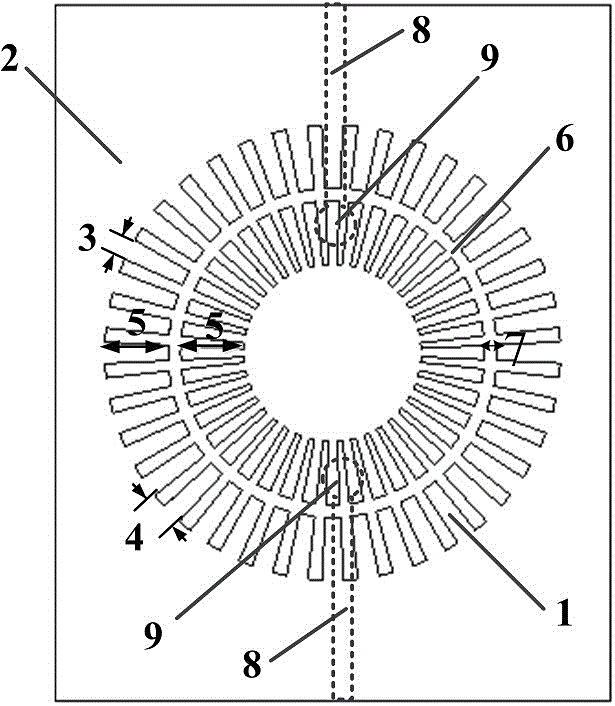

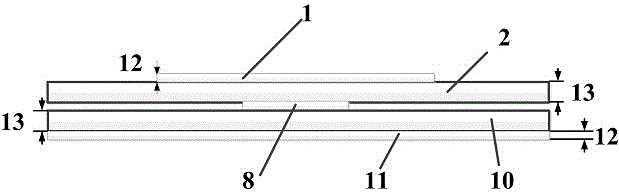

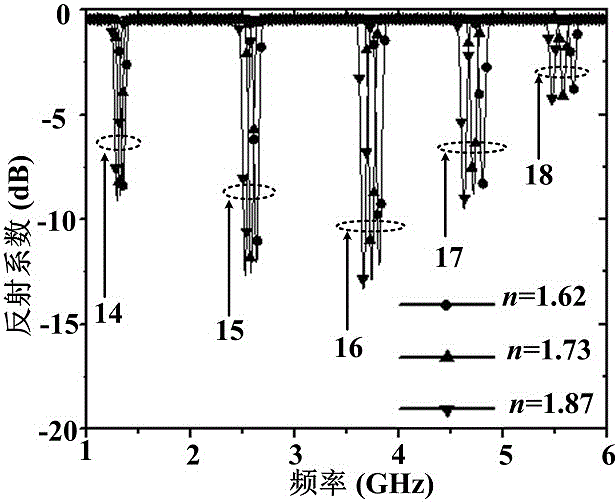

[0014] see figure 1 with figure 2 , a grooved ring structure sensor based on microstrip line excitation, including a grooved metal ring structure 1, a first dielectric layer 2, a second dielectric layer 10 and a ground plate 11 from bottom to top, the grooved metal ring structure The ring structure 1 includes an annular grooved metal strip 6, on which a plurality of grooves uniformly distributed along the circumferential direction are etched; between the first dielectric layer 2 and the second dielectric layer 10, a There is a microstrip line 8, and the microstrip line 8 is composed of a short metal patch and a disc branch structure 9 at the end of the metal patch; the microstrip line 8 can efficiently stimulate the artificial Surface plasmon waves.

[0015] In this embodiment, the groove width 3 of the grooved metal strip is 1.13mm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com