Polarizing plate

A polarizing plate and polarizing film technology, applied in the field of polarizing plates, can solve problems such as insufficiency, and achieve the effect of low cost and low manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

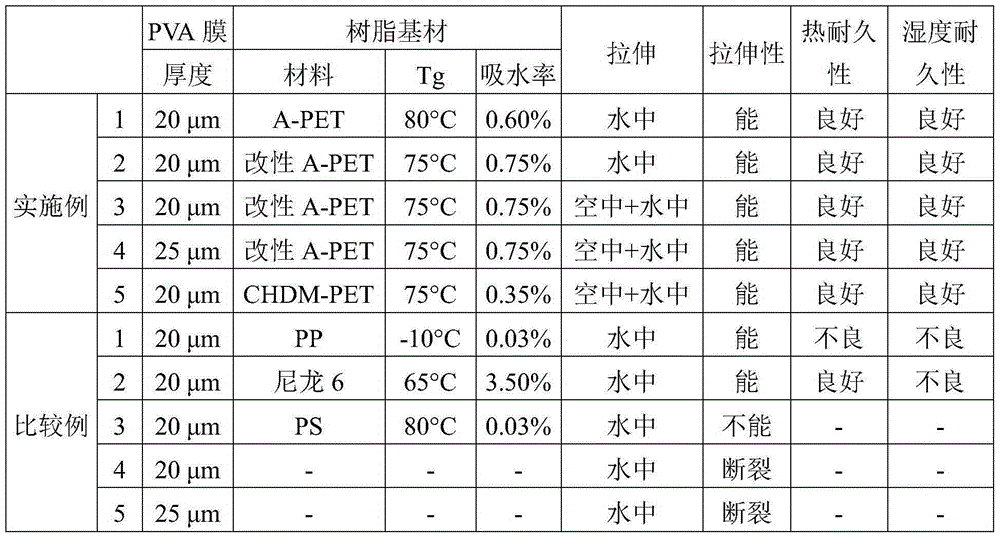

Embodiment 1

[0078] (manufacture of laminated body)

[0079] A polyvinyl alcohol film (polymerization degree: 2,400, saponification degree: 99.9 mol %) having a thickness of 20 μm and a resin substrate were used with a PVA-based resin aqueous solution (manufactured by The Nippon Synthetic Chemical Industry Co., Ltd., trade name: "GOHSEFIMER (trademark) Z -200", resin concentration: 3wt%) are laminated on each other as a binder to manufacture a laminated body. Amorphous polyethylene terephthalate (A-PET) film with a thickness of 100 μm and a corona-treated surface (manufactured by Mitsubishi Plastics, Inc., trade name: “NOVACLEAR”, Tg: 80° C., water absorption : 0.60%) was used as the resin substrate.

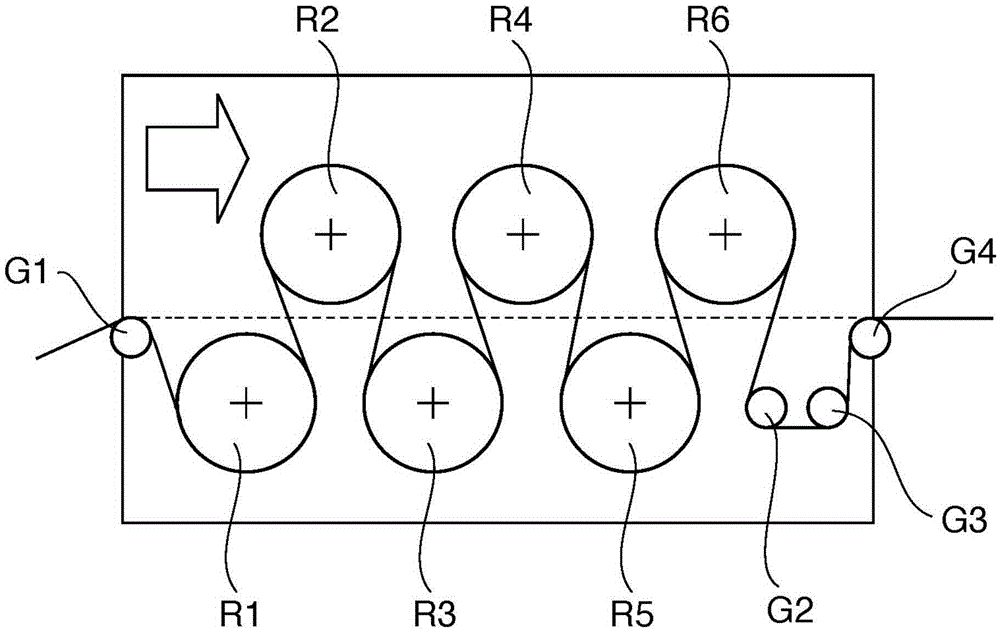

[0080] (manufacture of polarizing plate)

[0081] The obtained laminate was immersed in a swelling bath (pure water) at a liquid temperature of 30° C. (swelling treatment).

[0082] Next, the laminate was immersed in a dyeing bath at a liquid temperature of 30° C. while adjusting the iodi...

Embodiment 2

[0089] Except that an amorphous isophthalic acid-copolymerized polyethylene terephthalate (IPA-copolymerized PET) film (Tg: 75°C, water absorption: 0.75%) with a thickness of 100 μm was used as the A polarizing plate was manufactured in the same manner as in Example 1 except for the resin base material under manufacture.

Embodiment 3

[0091] (manufacture of laminated body)

[0092] A polyvinyl alcohol film (polymerization degree: 4,300, saponification degree: 99.3 mol %) having a thickness of 20 μm and a resin substrate were used with a PVA-based resin aqueous solution (manufactured by The Nippon Synthetic Chemical Industry Co., Ltd., trade name: "GOHSEFIMER (trademark) Z -200", resin concentration: 3wt%) are laminated on each other as a binder to manufacture a laminated body. An amorphous isophthalic acid-copolymerized polyethylene terephthalate (IPA-copolymerized PET) film (Tg: 75° C., water absorption: 0.75%) having a thickness of 100 μm and having a corona-treated surface was used as Resin base.

[0093] (manufacture of polarizing plate)

[0094] The obtained laminate was subjected to free-end uniaxial stretching (in-air stretching) at 2.0 times in the longitudinal direction (longitudinal direction) between rolls at different peripheral speeds in an oven at 120°C.

[0095] Next, the obtained laminate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com