A kind of flexible self-supporting graphene conductive film with microstructure pattern on the surface and its preparation method

A technology of conductive film and microstructure, applied in the direction of graphene, conductive layer on insulating carrier, cable/conductor manufacturing, etc. Efficient large-scale manufacturing and other issues to achieve the effect of low cost, high conductivity, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

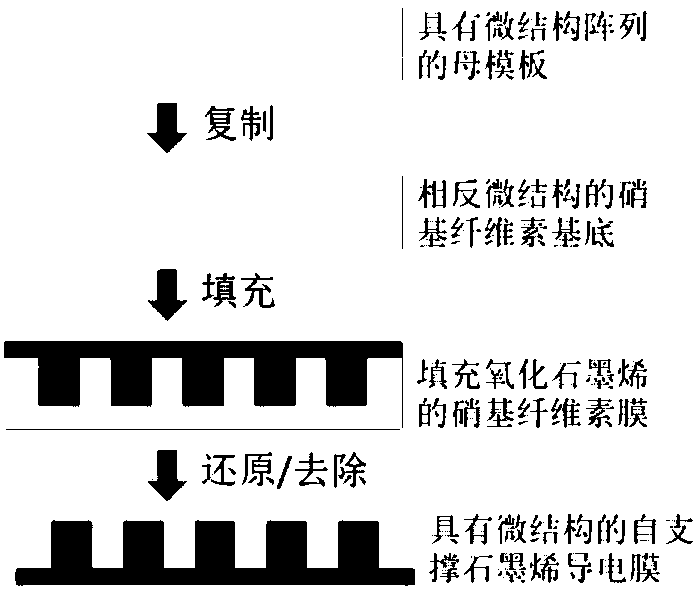

[0036] Example 1: Preparation of flexible self-supporting graphene conductive film with hole array pattern

[0037](1) According to the improved Hummers method (documentation ACS Nano 4 (8): 4806 (2010), Improved synthesis of graphene oxide), with graphite as raw material, the preparation concentration is the graphene oxide aqueous solution of 1.5mg / ml, wherein graphene oxide The size of the nitrocellulose is 100nm ~ 5um; prepare a DMF solution of nitrocellulose with a concentration of 5wt%

[0038] (2) Using a silicon wafer with a hole array pattern as a master template (where the hole diameter is 30um, the hole depth is 30um, and the hole spacing is 30um), the nitrocellulose solution is filled into the master template, and further vacuum-dried at 65 degrees Celsius 3h, the nitrocellulose film was obtained; the nitrocellulose was peeled off from the master template to obtain a nitrocellulose film with a pillar microstructure as a substrate.

[0039] (3) The nitrocellulose su...

Embodiment 2

[0042] Embodiment 2: the preparation of the flexible self-supporting graphene film of stripe array

[0043] (1) According to the improved Hummers method (document ACS Nano 4 (8): 4806 (2010), Improvedsynthesis of graphene oxide), take graphite as raw material, prepare the graphene oxide aqueous solution that concentration is 3mg / ml, wherein the graphene oxide The size is between 100nm and 5um; prepare a DMF solution of nitrocellulose with a concentration of 7.5wt%

[0044] (2) Using the PDMS film with a stripe array structure on the surface as the master template (where the bottom width of the stripes is 300um, the height is 100um, and the spacing is 300um), the nitrocellulose solution is filled into the master template, and further vacuum-dried at 90 degrees Celsius After 2.5 hours, a nitrocellulose film was obtained; the nitrocellulose was peeled off from the master template to obtain a nitrocellulose film with a hole array as a substrate.

[0045] (3) The nitrocellulose su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com