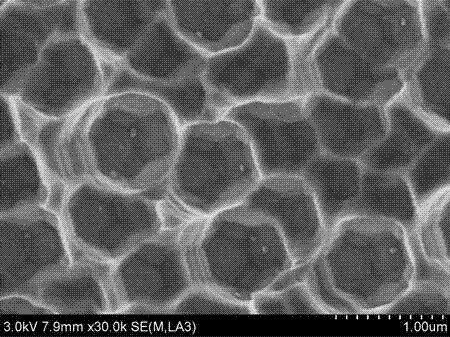

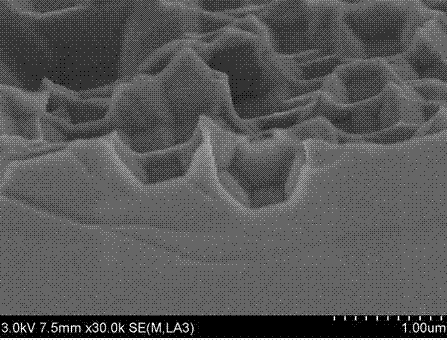

Polycrystalline silicon surface honeycomb structure and preparation method thereof

A polysilicon, honeycomb-shaped technology, applied in the field of technical solar cells, can solve problems such as deep defects and small structures, and achieve the effect of improving electrical properties, good reflectivity, and wide application in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a polycrystalline silicon surface honeycomb structure, comprising the following steps:

[0031] S1. Place the polysilicon wafer in solution A for cleaning to remove the mechanically damaged layer on the surface of the polysilicon wafer;

[0032] Said solution A comprises according to volume percent concentration: HF6%, HNO 3 33%, DI pure water 61%, including HF, HNO 3 Neither contains water;

[0033] S2. Prepare the cleaned polysilicon wafers as black silicon by using metal ion assisted etching method or femtosecond laser pulse method or reactive ion etching method to prepare black silicon wafers;

[0034] S3, soaking the prepared black silicon wafer to remove residual metal particles;

[0035] S4. Place the cleaned black silicon wafer in solution C for structural reconstruction, and then place the reconstituted black silicon wafer in solution D for treatment, so that a honeycomb structure can be prepared on the surface of the polycrystalline s...

Embodiment 2

[0047] A method for preparing a polycrystalline silicon surface honeycomb structure, comprising the following steps:

[0048] S1. Place the polysilicon wafer in solution A for cleaning to remove the mechanically damaged layer on the surface of the polysilicon wafer;

[0049] Said solution A comprises according to volume percent concentration: HF3%, HNO 3 15%, DI pure water 82%;

[0050] S2. Prepare the cleaned polysilicon wafers as black silicon by using metal ion assisted etching method or femtosecond laser pulse method or reactive ion etching method to prepare black silicon wafers;

[0051] S3, soaking the prepared black silicon wafer to remove residual metal particles;

[0052] S4. Place the cleaned black silicon wafer in solution C for structural reconstruction, and then place the reconstituted black silicon wafer in solution D for treatment, so that a honeycomb structure can be prepared on the surface of the polycrystalline silicon wafer ;

[0053] The solution C in t...

Embodiment 3

[0063] A method for preparing a polycrystalline silicon surface honeycomb structure, comprising the following steps:

[0064] S1. Place the polysilicon wafer in solution A for cleaning to remove the mechanically damaged layer on the surface of the polysilicon wafer;

[0065] Said solution A comprises: HF10%, HNO 3 38%, DI pure water 52%;

[0066] S2. Prepare the cleaned polysilicon wafers as black silicon by using metal ion assisted etching method or femtosecond laser pulse method or reactive ion etching method to prepare black silicon wafers;

[0067] S3, soaking the prepared black silicon wafer to remove residual metal particles;

[0068] S4. Place the cleaned black silicon wafer in solution C for structural reconstruction, and then place the reconstituted black silicon wafer in solution D for treatment, so that a honeycomb structure can be prepared on the surface of the polycrystalline silicon wafer ;

[0069] The solution C in the S4 includes: HF8%, HNO 3 20%, H 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com