Transparent laminated glass based on grids, preparation method and window carrier

A laminated glass and transparent technology, applied in windshields, parallel glass structures, chemical instruments and methods, etc., can solve problems such as the inability to apply hyperboloid glass, affecting the sight of drivers and passengers, and the inability of flexible substrates to stretch, etc. Achieve the effect of large-area mass production, improved curved glass compatibility, improved safety and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

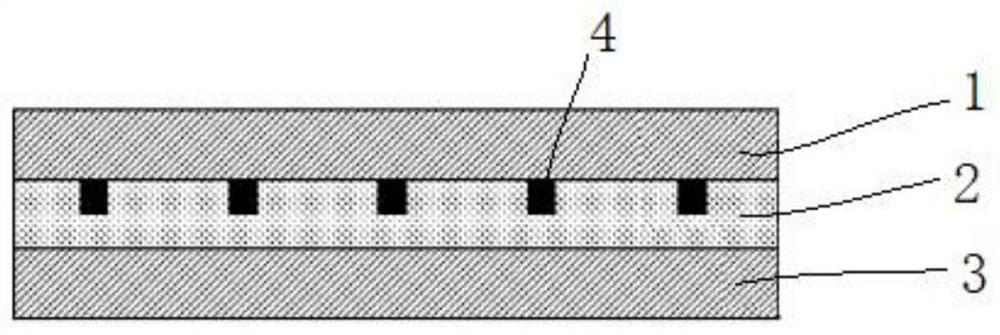

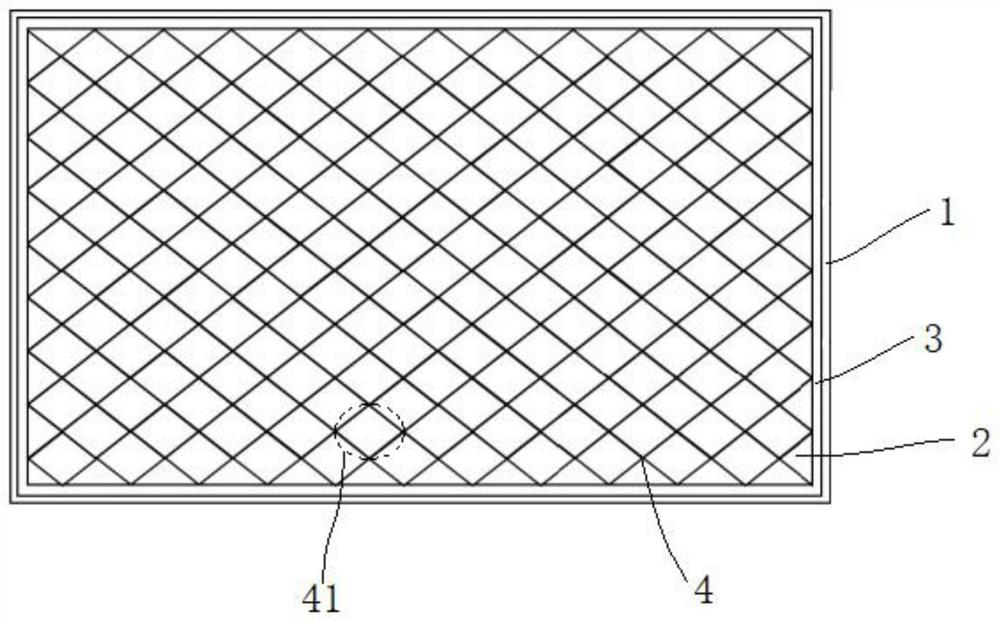

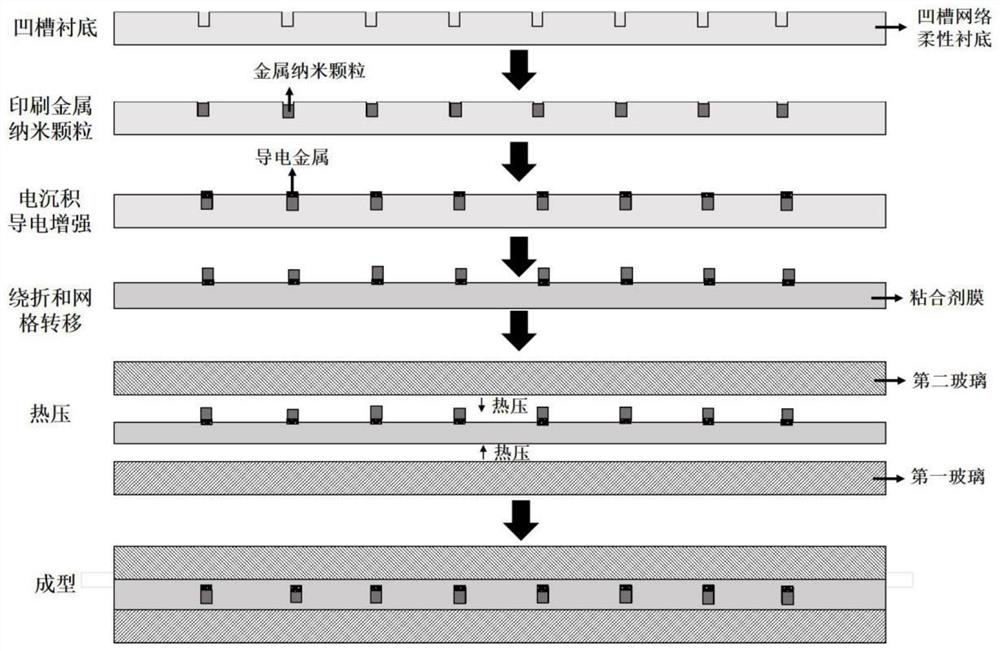

[0065] First, a groove structure is formed on the PET substrate (the groove structure is hexagonal, the period is 80 μm, the groove line width is 2.5 μm, and the groove depth is 3 μm), and then a 2 μm thick silver nanometer is formed in the groove by printing. Particle layer, at this time, the adhesion between the silver nanoparticles and the groove is 3B; then, 2 μm thick copper is deposited on the surface of the silver nanoparticles by electrodeposition, and its conductivity is further enhanced to form a metal mesh transparent conductive film; then use The roller with a roller diameter of 10mm is wound and folded 3 times, then the metal grid conductive film is placed on the PVB, and hot-pressed once with a 50°C roller to remove the PET, and the metal grid is transferred to the PVB at this time; finally The transferred PVB and the metal grid are sandwiched between two pieces of hyperbolic glass, and vacuum hot-pressed at 140°C for 1 hour to form a hyperbolic transparent electr...

Embodiment 12

[0067] First, a groove structure is formed on the PET substrate (the groove structure is a regular triangle, the period is 50 μm, the groove line width is 2 μm, and the groove depth is 0.2 μm), and then a 0.1 μm thick silver nanometer is formed in the groove by printing. Particle layer, at this time, the adhesion between the silver nanoparticles and the groove is 3B; then deposit 0.1 μm thick copper on the surface of the silver nanoparticles by electrodeposition, further enhance its conductivity, and form a metal grid transparent conductive film; then Use a roller with a diameter of 1mm to fold 3 times, then place the metal grid conductive film on the PVB, and use a 40°C roller to heat press 3 times to remove the PET. At this time, the metal grid is transferred to the PVB; finally The transferred PVB and metal grid are sandwiched between two pieces of hyperbolic glass, and vacuum hot-pressed at 100°C for 1 hour to form a hyperbolic transparent electromagnetic shielding glass. ...

Embodiment 13

[0069] First, a groove structure (groove structure is square, period 200 μm, groove line width 7 μm, groove depth 14 μm) is formed on the PET substrate, and then a 2 μm thick silver nanoparticle layer is formed in the groove by printing method, At this time, the adhesion between the silver nanoparticles and the groove is 2B; then, 12 μm thick copper is deposited on the surface of the silver nanoparticles by electrodeposition, and its conductivity is further enhanced to form a metal mesh transparent conductive film; then use the roller diameter Fold once for a 10cm roller, place the metal grid conductive film on the PVB, and heat press it twice with a 100°C roller to remove the PET. At this time, the metal grid is transferred to the PVB; finally, the transferred PVB It is sandwiched between two pieces of hyperbolic glass with a metal grid, and vacuum-pressed at 150°C for 1 hour to form a hyperbolic transparent electromagnetic shielding glass. The square resistance of the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com