Device and method for fast preparing large-area vertically aligned graphene

A vertically oriented, large-scale technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as hindering the preparation and application of high-quality nanomaterials, affecting the growth rate and growth area of graphene, etc. The effect of reducing the amount of consumption and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

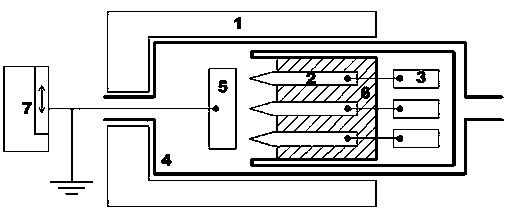

[0051] 1. The multi-cone electrode 2 is composed of an array comprising three conical electrodes. The adjacent conical electrodes are parallel and separated by ceramic insulators 6 with a spacing of 10 mm. The taper of a single conical electrode in the multi-cone electrode 2 is 1. :10. Each cone-shaped electrode in the multi-cone electrode 2 is powered by an independent high-voltage negative power supply 3 .

[0052] 2. Select a stainless steel sheet with a thickness of 0.025 mm as the substrate 5 . The base 5 faces the cone tips of the multi-cone electrodes 2 with a distance of 20 mm. Substrate 5 is grounded.

[0053] 3. The base 5 , the multi-cone electrode 2 and the ceramic insulator 6 are placed in the quartz tube 4 , and the quartz tube 4 is placed in the heating furnace 1 .

[0054] 4. The substrate 5 is connected to the electric translation stage 7 .

[0055] 5. Pass the mixed gas of hydrogen and argon into the quartz tube 4 (total flow rate: 2000 ml / min; volume rat...

Embodiment 2

[0061] Repeat Example 1, the only difference is: in step 1, the taper of a single conical electrode in the multi-cone electrode 2 is 1:20, and the distance between parallel conical electrodes is 5 mm; in step 2, choose not to The regular porous carbon film is used as the substrate, and the distance between the substrate and the tip of the multi-cone electrode is 10 mm; in step 5, it is heated to 800 by a heating furnace o C; in step 6, keep 800 o C heating, the relative humidity of the mixed gas is 55.2%, the distance between the base and the tip of the multi-cone electrode is kept constant at 10 mm, the discharge voltage is 3.5 kV, the translation speed is 1 mm / s, and the discharge duration is 30 seconds; 7, keep the furnace temperature at 800 o c.

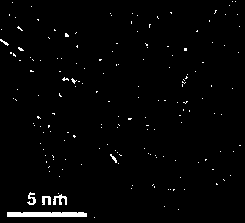

[0062] Through the above steps, a layer of vertically oriented graphene nanosheets can be evenly covered on the surface of the irregular porous carbon film. image 3 Shown is a scanning electron micrograph of a vertically orie...

Embodiment 3

[0064] Repeat Example 1 with the only difference that: in step 1, the taper of a single tapered electrode in multi-tapered electrode 2 is 1:3, and the distance between parallel tapered electrodes is 10 mm; in step 2, the thickness The gold foil of 0.025 mm is used as the substrate, and the distance between the substrate and the tip of the multi-cone electrode is 20 mm; in step 5, it is heated to 600 by a heating furnace o C; in step 6, keep 600 o C heating, the relative humidity of the mixed gas is 31.4%, the distance between the base and the tip of the multi-cone electrode is kept constant at 20 mm, the translation speed is 0.01 mm / s, the discharge voltage is 6 kV, and the discharge duration is 1 hour; 7, keep the furnace temperature at 600 o c.

[0065] Through the above steps, a layer of vertically oriented graphene nanosheets can be covered on the gold foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com