A Method for Controlling Residual Stress and Deformation of Welded Joint Filled on One Side of Thick Plate

A welding joint and residual stress technology, applied in welding/welding/cutting items, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult orthosis, high residual stress of joints, large deformation, etc., to achieve convenient operation and reduce residual stress and deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

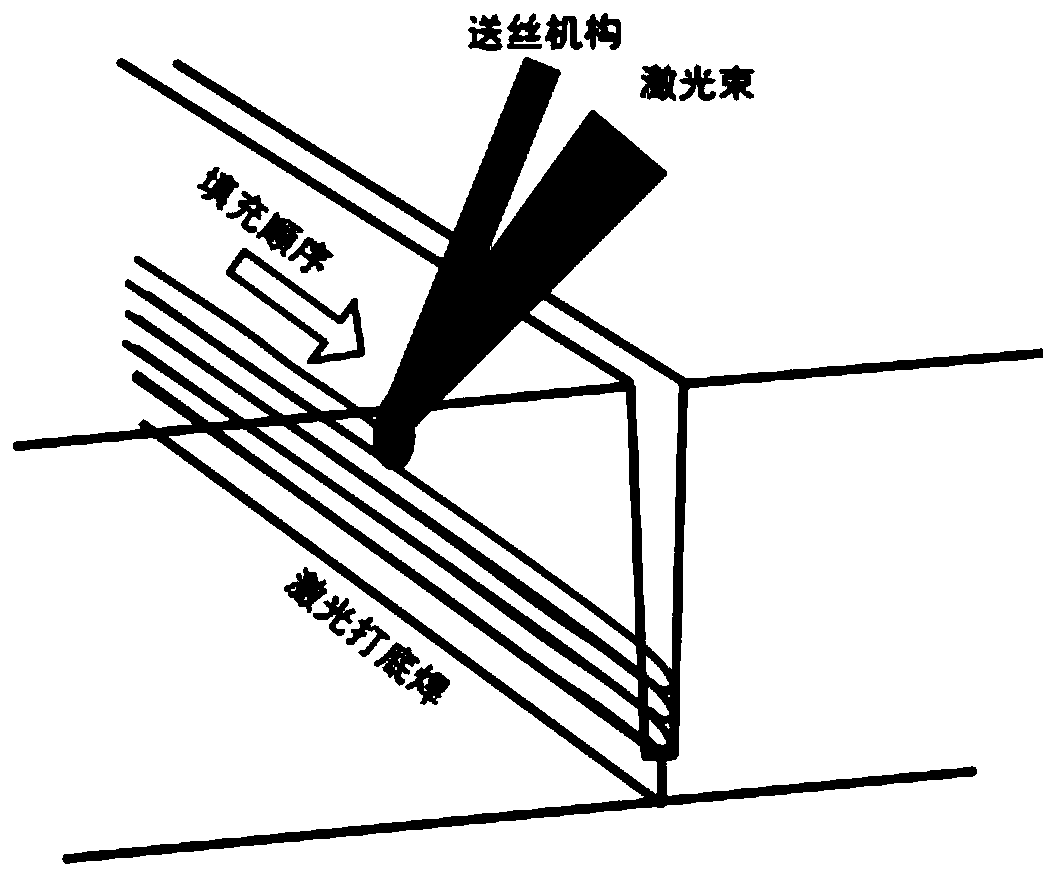

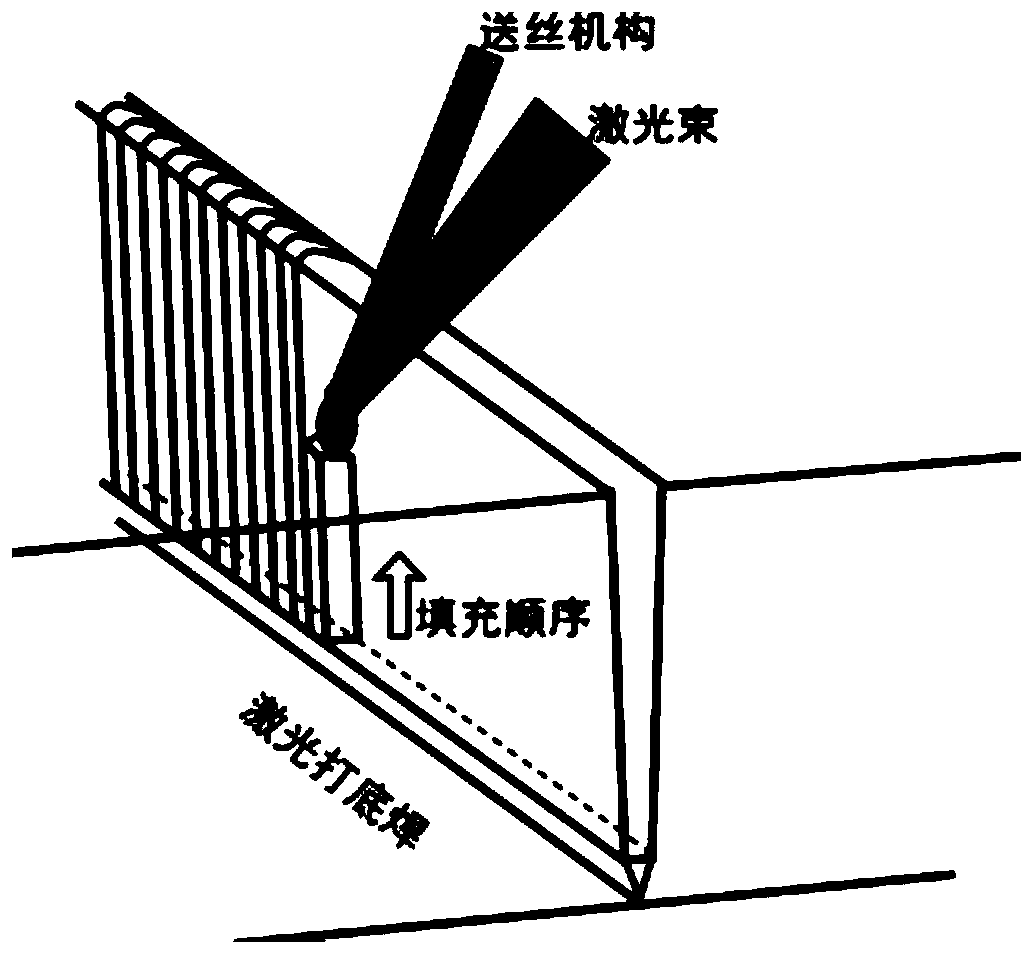

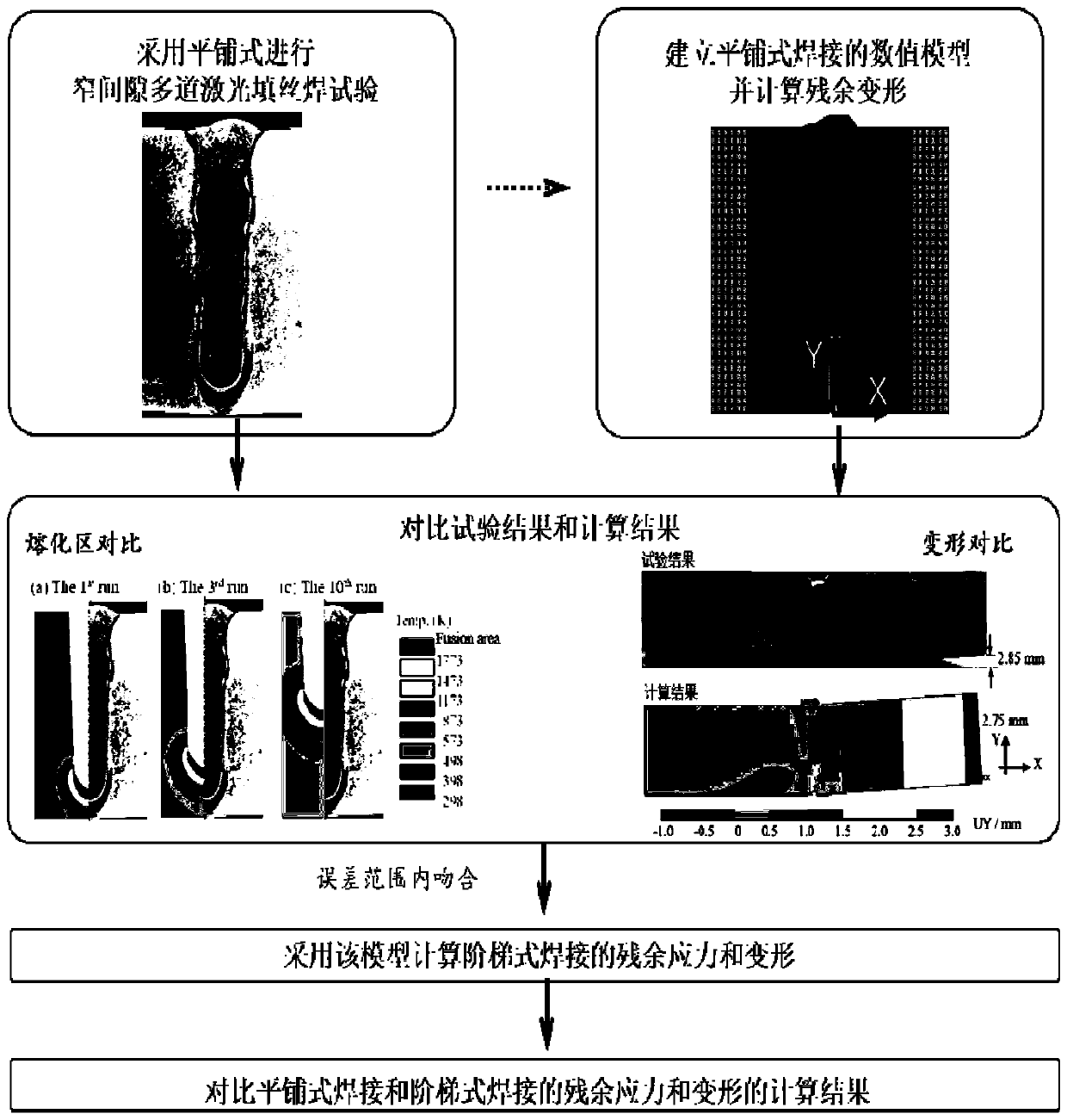

[0035] Take the 20mm thick and 90mm long D406A high-strength steel plate as an example. In this embodiment, two kinds of welding sequences are involved, conventional tiled (weld seam horizontal growth) and stepped (in the present invention), such as Figure 1a and Figure 1b shown. This example demonstrates the effect of adopting the vertical growth welding sequence of the weld seam on reducing the residual stress and deformation of the welded joint of thick plate fusion filler wire through the method of combining test and calculation. The specific process is as follows figure 2 shown.

[0036] First of all, the conventional welding sequence is used to perform multi-pass laser wire-filling welding on the 20mm thick D406A high-strength steel plate to measure the residual stress and deformation of the joint. The main steps are as follows: pre-processing a small-sized groove for a plate with a thickness of 20mm, and the shape of the groove Such as image 3 As shown, there is ...

Embodiment 2

[0041] Taking OD1219×18.4mm specification X80 butt girth weld repair as an example, the depth of the repair welding area is 12mm, the width is 15mm, and the length is 200mm. In this example, two welding sequences, conventional tiled (horizontal growth of the weld) and stepped (vertical growth of the weld) are involved to repair the root welding position of the X80 pipe body, and the thermal welding is completed by using ANSYS finite element software and indirect coupling -Structural analysis, respectively obtain the stress field of ordinary tiled welding sequence and the present invention, from Figure 8a and Figure 8b It can be seen that the X80 pipe girth weld is repaired with a stepwise welding sequence based on the vertical growth of the weld, so that the weld grows vertically, the maximum equivalent stress of the weld after welding is reduced by about 49 MPa, and the maximum axial stress is reduced About 96MPa, and the area of the high stress area is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com