A kind of preparation method of black silicon MWT back contact cell

A technology of back contact battery and black silicon, which is applied in the field of technical solar cells, can solve the problems of reduced yield rate, high fragmentation rate, and reduced surface reflectivity of silicon wafers, etc., to achieve reduced reflectivity, low cost, and large-area mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

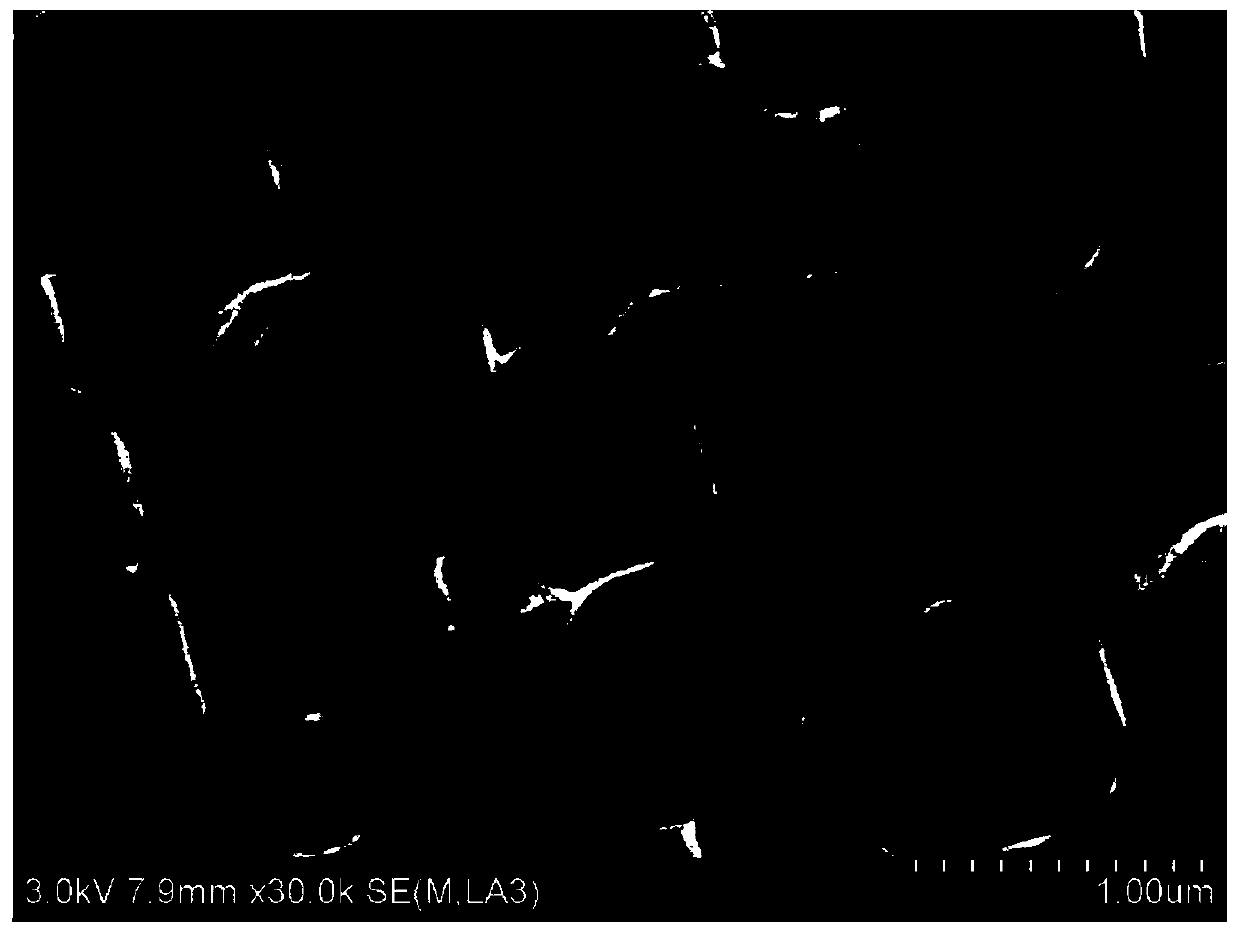

Image

Examples

Embodiment 1

[0021] A kind of preparation method of black silicon MWT back contact cell, comprises the following steps:

[0022] S1. Perform damage removal treatment on the surface of the polysilicon wafer; place the polysilicon wafer in a solution for cleaning. The solution ratio and volume percentage concentration are: HF6%, HNO 3 3%, DI pure water 91%, including HF, HNO 3 Neither contains water;

[0023] S2. Print metal paste on the position where holes need to be opened on the surface of the polysilicon wafer; the composition of the metal paste is composed of nano-silver particles, resin, organic solvent and others, calculated according to mass percentage, wherein the nano-silver particles are 10%, and the resin is 55%. %, organic carrier is 30%, others are 5%; the organic carrier is divided into ethyl cellulose 5%, butyl carbitol acetate, dioctyl phthalate, diethylene glycol butyl ether by weight percentage A combination of 45% (these three substances are of the same quality), terpi...

Embodiment 2

[0030] A kind of preparation method of black silicon MWT back contact cell, comprises the following steps:

[0031] S1. Perform damage removal treatment on the surface of the polysilicon wafer; place the polysilicon wafer in a solution for cleaning. The solution ratio and volume percentage concentration are: HF6%, HNO 3 3%, DI pure water 91%, including HF, HNO 3 Neither contains water;

[0032] S2. Print the metal paste on the position where holes need to be opened on the surface of the polysilicon wafer; the composition of the metal paste is composed of nano-silver particles, resin, organic solvent and others, calculated according to the mass percentage, wherein the nano-silver particles are 30%, and the resin is 50% %, organic matter carrier is 18%, other 2%. The printed graphics and area are determined according to the punching position of the cell design graphics, and the printing thickness is 50um. The resin is high molecular weight epoxy resin and polyurethane, and th...

Embodiment 3

[0039] A kind of preparation method of black silicon MWT back contact cell, comprises the following steps:

[0040] S1. Perform damage removal treatment on the surface of the polysilicon wafer; place the polysilicon wafer in a solution for cleaning. The solution ratio and volume percentage concentration are: HF6%, HNO 3 3%, DI pure water 91%, including HF, HNO 3 Neither contains water;

[0041] S2. Print the metal paste on the position where holes need to be opened on the surface of the polysilicon wafer; the composition of the metal paste is composed of nano-silver particles, resin, organic solvent and others, calculated according to the mass percentage, wherein the nano-silver particles are 15%, and the resin is 40% %, organic matter carrier is 40%, other 5%. The printed graphics and area are determined according to the punching position of the cell design graphics, and the printing thickness is 20um. Described resin is the mixture of imide, phenolic resin, saturated poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com