COB encapsulation method

A packaging method and technology for printed circuit boards, which are used in electrical components, circuits, semiconductor devices, etc., can solve problems such as product defects, short circuits, and affect product appearance, and achieve cutting speed improvement, cut damage reduction, carbonization and debris. Phenomenon improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with specific embodiment, further illustrate the present invention.

[0054] A COB packaging method is characterized in that comprising the following steps:

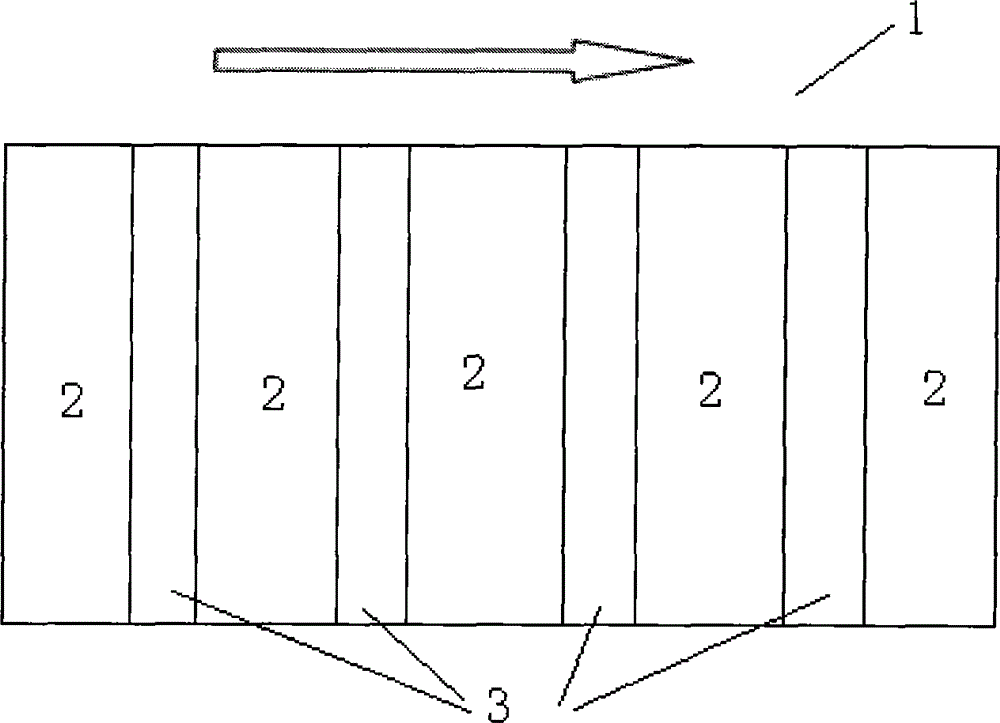

[0055] The first step: preparing a single-sided FPC board (1);

[0056] The second step: puncture the LED chip on the FPC printed circuit board with a thorn pen through the steps of crystal expansion, back glue and thorn;

[0057] Step 3: Put the thorny FPC printed circuit board into a thermal cycle oven to keep the temperature constant so that the silver paste on it is cured;

[0058] Step 4: Paste the chip, use black glue to paste the chip on the FPC board, and put it in a thermal cycle oven to cure;

[0059] Step 5: Bonding, bridge the chip with the corresponding pad on the FPC board;

[0060] Step 6: Pre-test, and rework the unqualified FPC board;

[0061] The seventh step: glue dispensing, use the glue dispenser to package the prepared glue.

[0062] Step 8: Curing, put the sealed FP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com