Device for automatically winding wound laminated battery

A winding battery technology, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of long pole piece, large gap of single electrode assembly, inconsistent tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

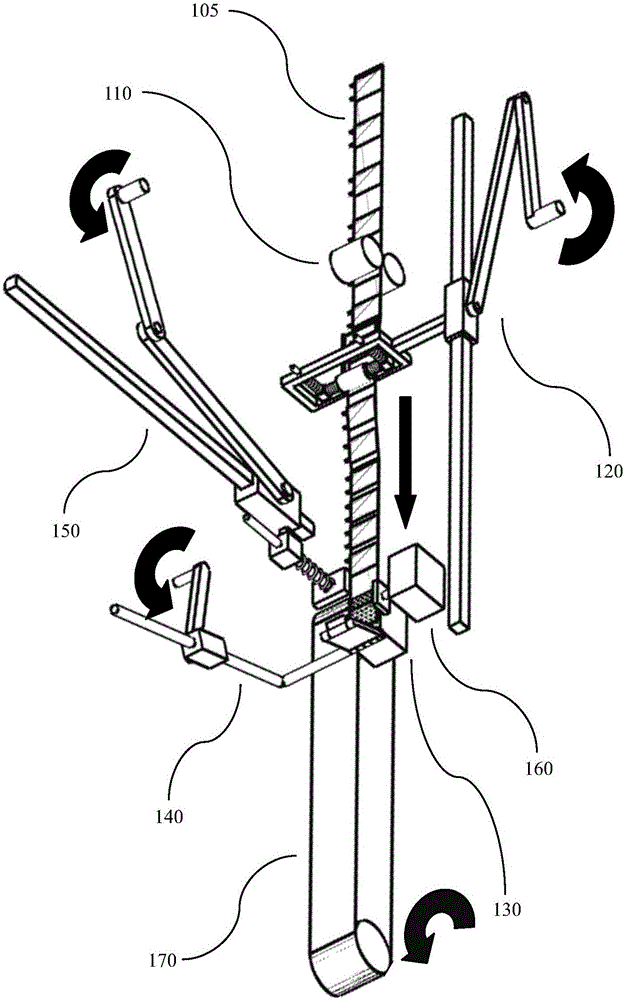

[0036] The present invention will be further described below in conjunction with accompanying drawing:

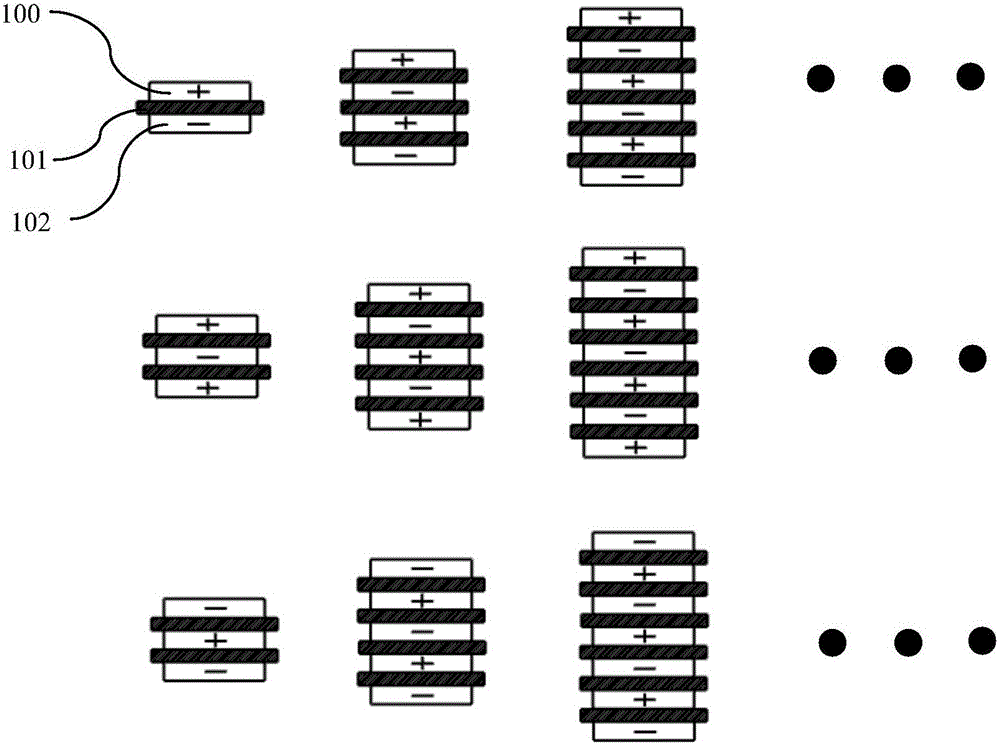

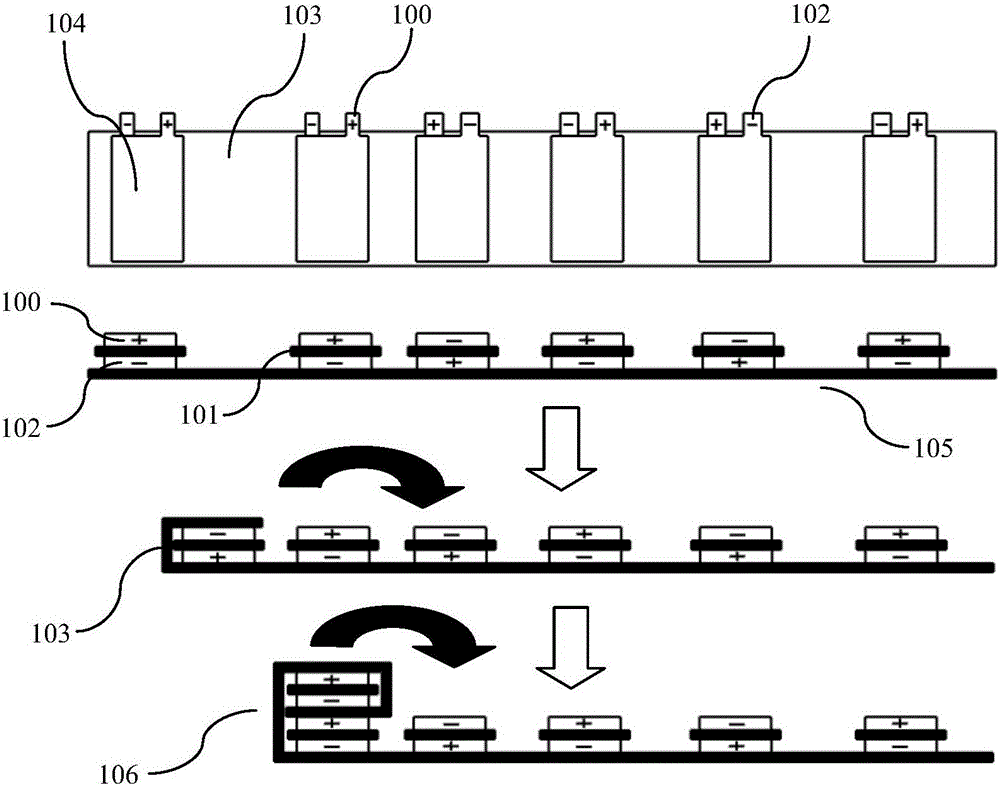

[0037] figure 1 and figure 2 It is a typical view of an exemplary structure of a single electrode assembly and its arrangement and bonding on a single-side glued adhesive separator in the present invention. The single electrode assembly 104 is obtained by a hot-pressing process from several layers of positive pole pieces 100, adhesive separators 101 coated on both sides, and negative pole pieces 102. figure 1 Three typical unit structures corresponding to the single electrode assembly applicable to the device of the present invention are shown, namely, positive electrode sheet / adhesive diaphragm / negative electrode sheet, positive electrode sheet / adhesive diaphragm / negative electrode sheet / adhesive diaphragm / positive electrode sheet, negative electrode sheet / adhesive separator / positive electrode sheet / adhesive separator / negative electrode sheet. A single electrode assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com