Ground rod and application method thereof

A technology of grounding rods and connecting rods, which is applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems of no anti-theft measures, increased construction costs, and unsuitable environments for corrosion, and achieve good anti-corrosion and conductive effects. Easy to recycle the ground electrode, good anti-theft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

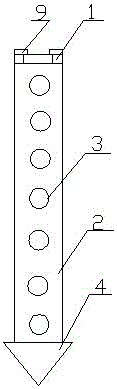

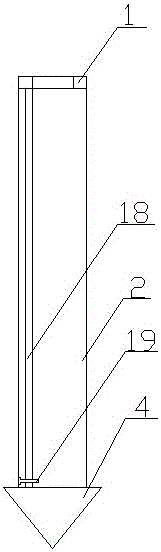

[0048] Embodiment 1: A grounding rod, including a connecting rod 2, a grounding rod 4 arranged on the lower part of the connecting rod 2 and a driving head arranged on the upper part of the connecting rod 2, and a drill bit is arranged at the end of the connecting rod 4, so that The outer diameter of the drill bit is greater than or equal to the outer diameter of the connecting rod 2, the outer wall of the connecting rod 2 is provided with a number of outward opening blind holes 3, and the connecting rod 2 is provided with a threading hole 18 passing through the blind hole 3 in the axial direction .

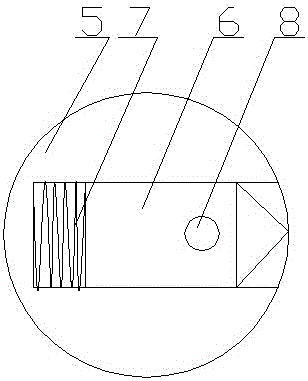

[0049] A fastener 6 is arranged in the blind hole 3 , and a compression spring 7 is arranged at the bottom of the fastener 6 .

[0050] The fastener 6 is provided with a through hole 8 matching with the threading hole 8 .

[0051] The lower part of the threading hole 18 is provided with a clamping module 19 for fixing the end of the tension rope, and the upper part of the thread...

Embodiment 2

[0055] Embodiment 2: The difference between it and Embodiment 1 is that scales are set on the tensioning rope 20 .

[0056] The blind hole 3 is a horizontal fan-shaped hole, and a horizontal fan-shaped fastener 16 is arranged in the horizontal fan-shaped hole.

[0057] Several holes 17 are set on the horizontal fan-shaped fastener 16 .

Embodiment 3

[0058] Embodiment 3: The difference from Embodiment 2 is that the outer wall of the fastener 6 is provided with a cutting edge.

[0059] The outer wall of the connecting rod 2 is provided with a copper plating layer of 1-2mm.

[0060] The surface of the fastener 6 is provided with a wire groove 22 for threading.

[0061] In this embodiment, a wire trough for easy threading is set, and when threading in the threading hole, it is convenient to guide the tension rope to enter the threading hole of the next fastener from the threading hole of the previous fastener, avoiding the The tight contact of the blind hole makes it difficult for the tension rope to pass through the threading hole, which reduces the threading time and improves the work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com