a direct current generator

A technology of DC generator and synchronous motor, applied in synchronous generator and other directions, can solve the problems of poor reliability, high failure rate of rotating rectifier, difficulty in demagnetization and adjustment and control, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

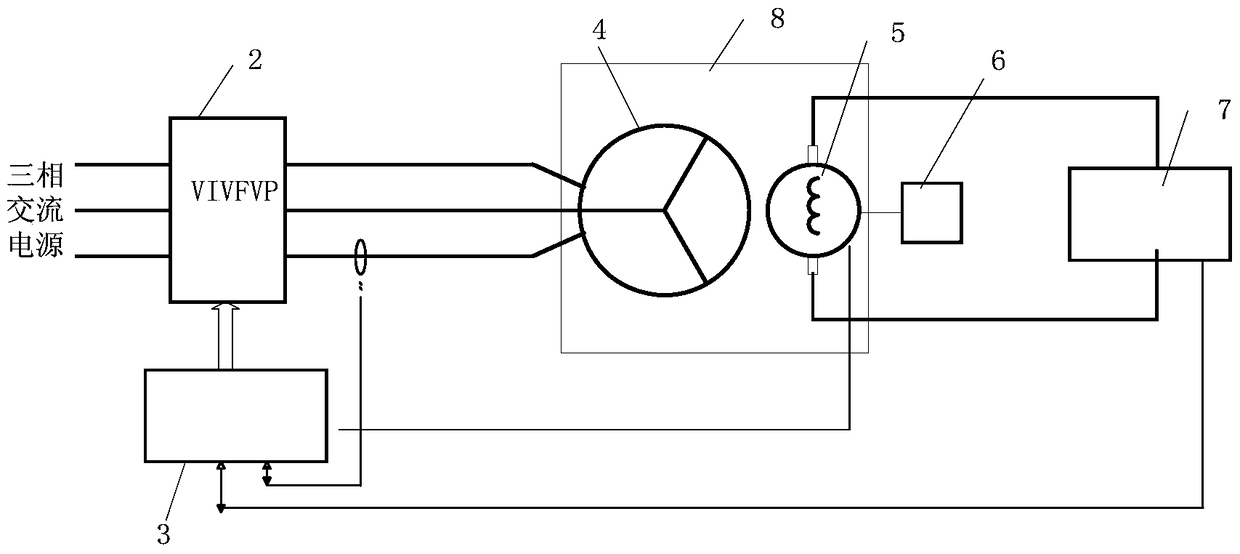

[0023] figure 1 A schematic structural diagram of a DC generator according to an embodiment of the present invention is shown.

[0024] refer to figure 1 , the DC generator 10 of the present invention includes a controller 3 , a converter 2 and a synchronous motor 8 .

[0025] The synchronous motor 8 includes a stator 4, a rotor 5, a prime mover 6, a field winding (not shown) mounted on the stator and an armature winding (not shown) mounted on the rotor, the prime mover 6 is mechanically connected to the rotor 5, Used to drive the rotation of the rotor 5.

[0026] In this embodiment, the potential of the rotor 5 is taken out through a brush slip ring (not shown) for connecting a DC load 7 .

[0027] The input terminal of the converter 2 is connected to the three-phase AC power supply, and the converter 2 converts the three-phase AC power output by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com