Battery module

一种电池模块、电池组的技术,应用在电池、二次电池、电池组零部件等方向,能够解决热不能被有效地释放、电池组操作状况和稳定性变差、电池组电阻改变等问题,达到优良充电和放电效率、优良循环性质、优良寿命性质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0073] [Example 1: Manufacture of battery modules]

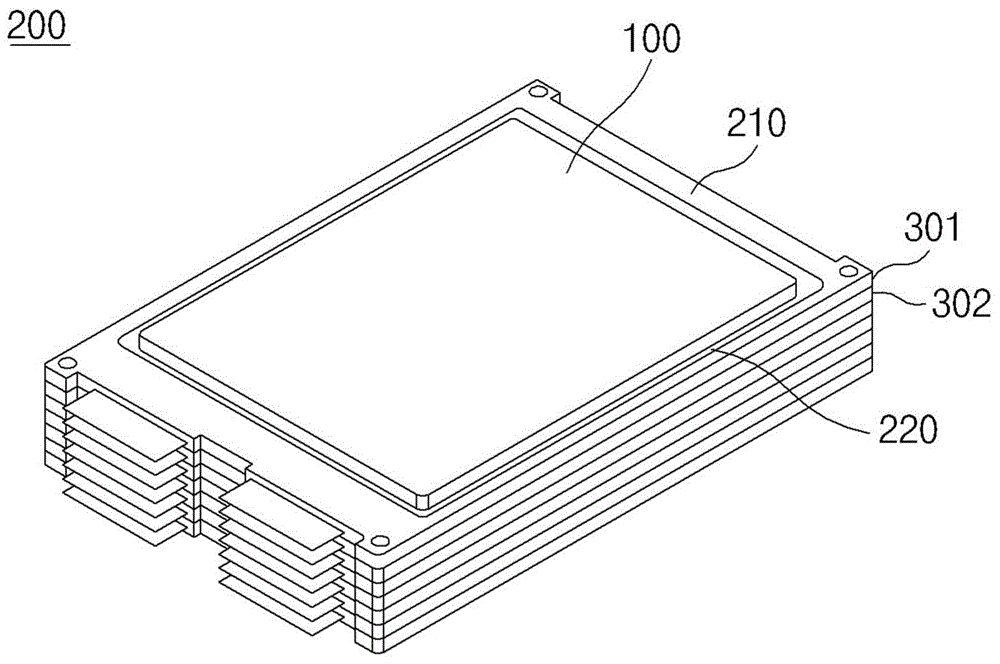

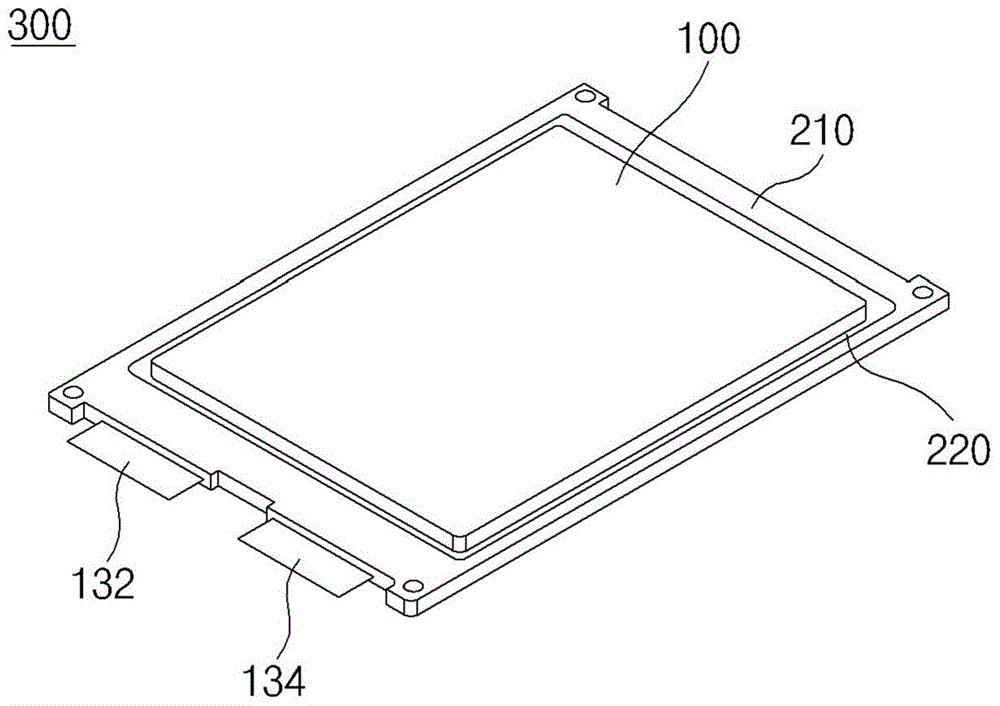

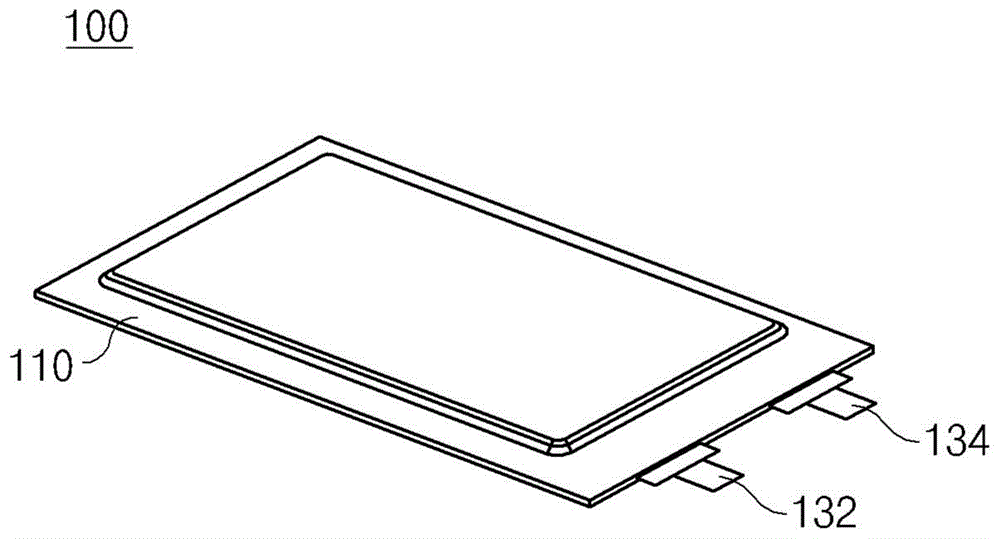

[0074] manufactured with as in Figure 1 to Figure 4 A battery module with the structure shown in .

[0075] Specifically, 97% by weight of artificial graphite, 1.5% by weight of carboxymethyl cellulose (CMC ) and a styrene-butadiene rubber (SBR) binder of 1.5% by weight to prepare an aqueous negative electrode slurry, and then coat the aqueous negative electrode slurry on a copper (Cu) foil, dry it, and roll it up to prepare a negative electrode.

[0076] In addition, by adding 95% by weight of LiCoO as a positive electrode active material to a mixed solvent of water and ethanol (mixed volume ratio of water and ethanol = 90:10) 2 , preparing a positive electrode slurry by 3% by weight of Super-P (conductor) and by 2% by weight of an SBR binder, and then coating the positive electrode slurry on an aluminum foil, drying it, and rolling it up to prepare a positive electrode.

[0077] After the electrode assembly is prepared...

example 2

[0079] [Example 2: Manufacture of battery modules]

[0080] A battery module was manufactured in the same manner as in Example 1 except that three battery cell units were laminated.

example 3

[0081] [Example 3: Manufacture of battery module]

[0082] In addition to coating the heat-absorbing material between each stacked battery cell when stacking the battery cells (cell #1, 2, 3, 4, 5, 6), further on the surface and A battery module was fabricated in the same manner as in Example 1 except that a heat absorbing material was formed between the facing surfaces of adjacent battery cell units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com