Laser processing device with linear array optical lens assembly with micro cylindrical lenses in cylindrical distribution

A micro-cylindrical lens and optical lens technology, which is applied in optics, optical components, laser welding equipment, etc., can solve the problems of difficult processing, not very strict optical path precision, and large processing area, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

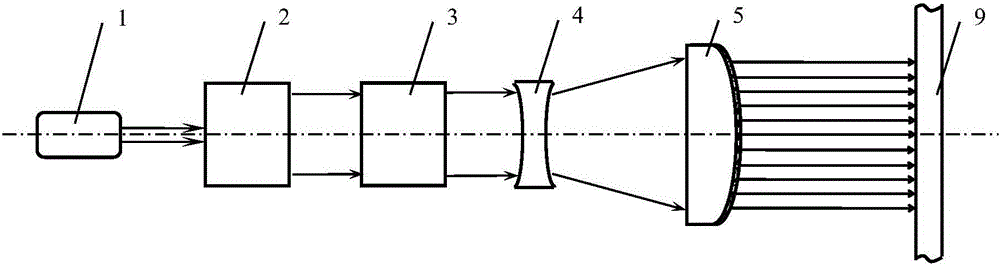

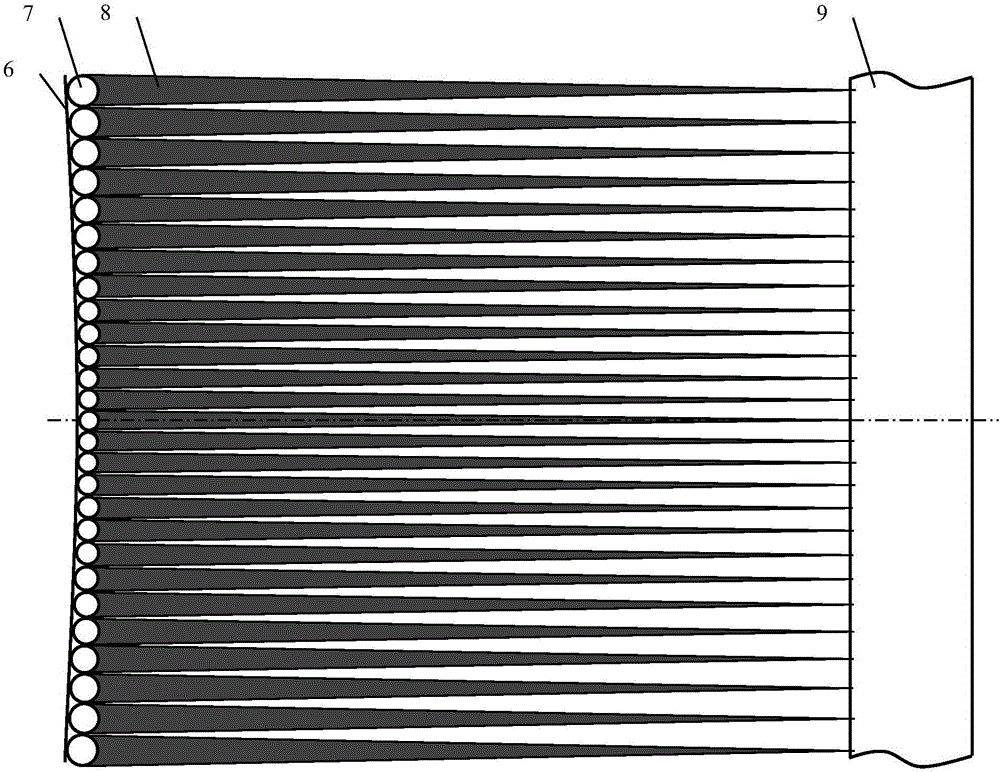

[0016] Such as figure 1 As shown, a laser light source 1, a collimating beam expander 2, a beam shaping mirror 3, a double-concave lens 4, and a linear array of micro-cylindrical lenses with cylindrical distribution are optically arranged coaxially in sequence.

[0017] The laser light source 1 is a high-power Nd:YAG pulsed solid-state laser with a wavelength of 1064nm, a pulse width of 8ns, a single pulse energy of 2J, a beam exit diameter of Φ8mm, and a divergence angle of 3mrad.

[0018] The beam expansion factor of the collimating beam expander 2 is 6.25, and it is composed of multiple optical lenses, the lens material is K9 glass, the mirror surfaces of the multiple optical lenses are all coated with AR1064nm, the incident diameter of the beam is Φ10mm, and the outgoing diameter of the beam is Φ50mm .

[0019] The beam shaping mirror 3 shapes the laser beam with circular spot and Gaussian distribution of light energy into a laser beam with square spot and uniform distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com