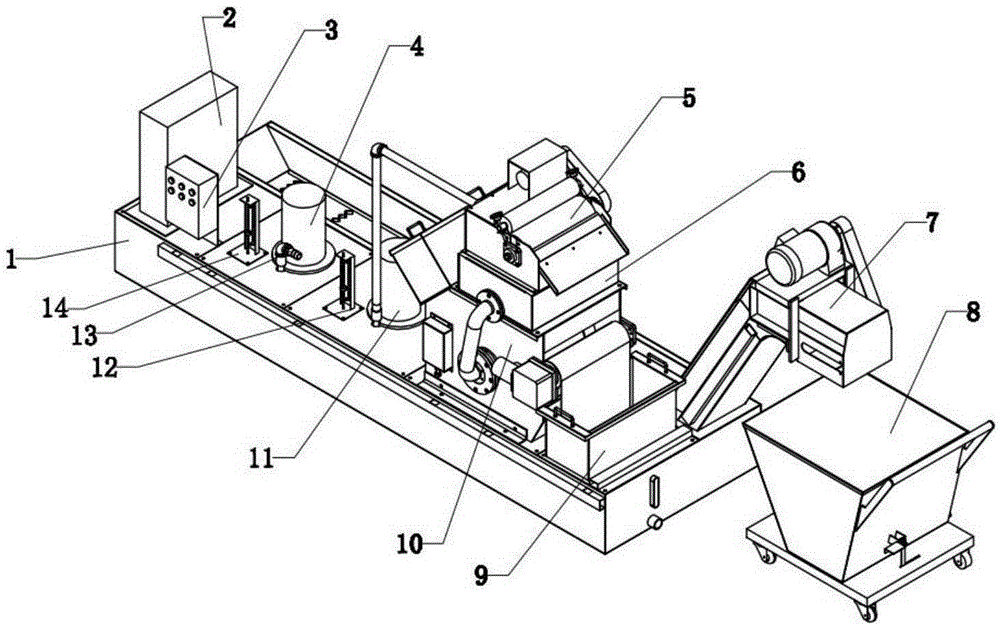

Combined chip removal and liquid recovery, filtration, cooling and cyclic utilization system for numerical control machine tool

A CNC machine tool and cooling cycle technology, applied in the field of CNC machine tools, can solve the problems of complex overall structure and poor cooling liquid filtration effect, and achieve the effect of simple and practical overall structure, small footprint and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

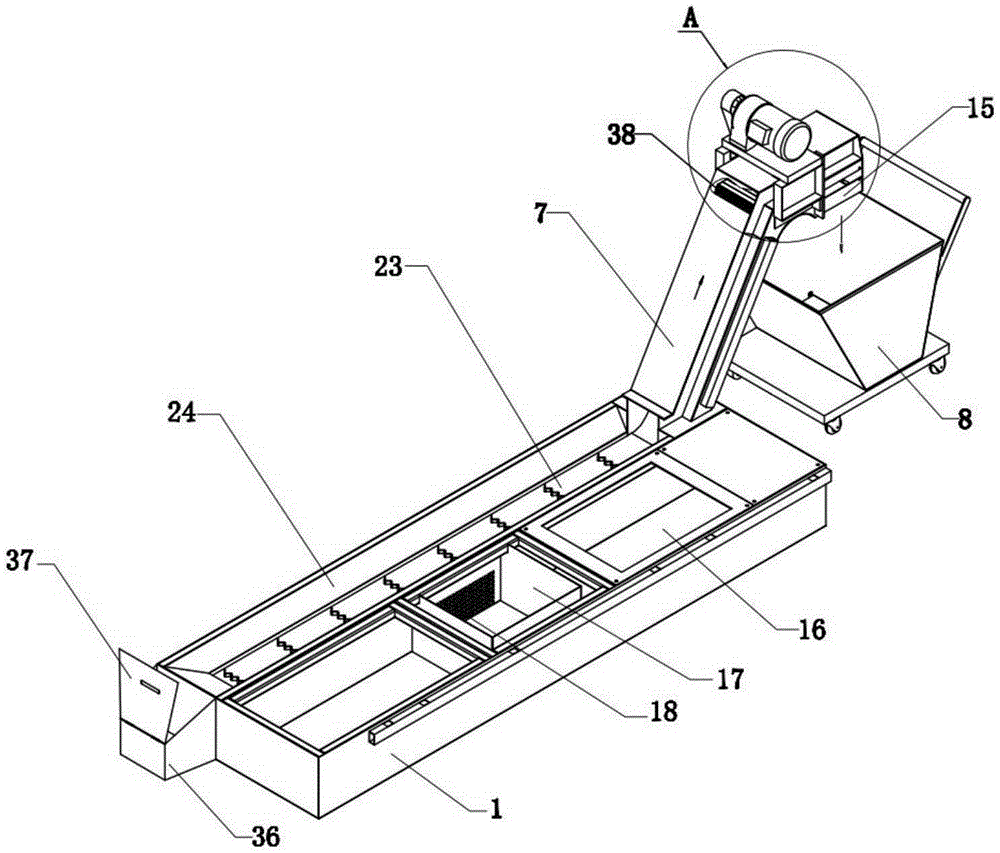

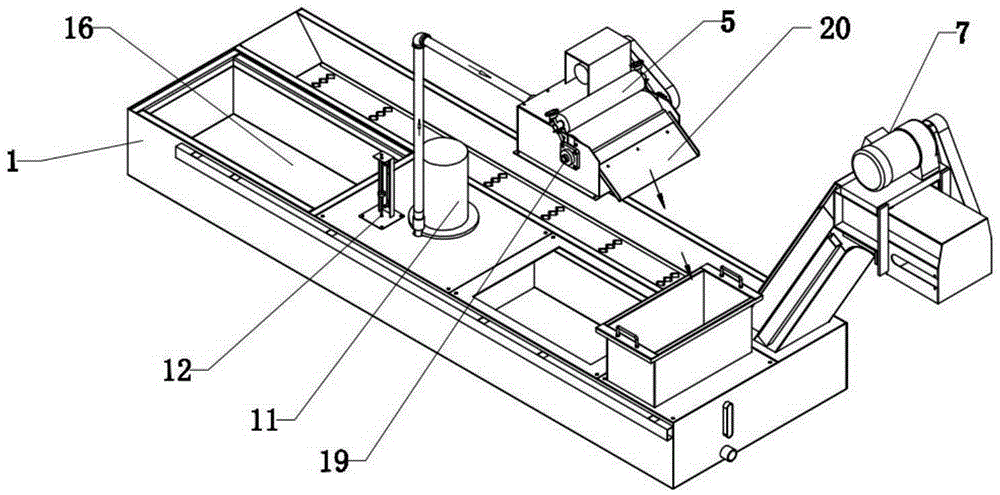

[0023] as attached Figure 1-Figure 5In the shown embodiment, the present invention is provided with: CNC machine tool main body 1, electrical control box 3, clean water tank 16, sewage tank 17, chip removal machine 7, magnetic separator 5, vertical paper tape filter 10, embedded liquid Cooling machine 2, recovery coolant storage tank 6, chip receiving tank 24, clean water tank 16, sewage tank 17, chip receiving tank 24, chip removal machine 7, magnetic Separator 5, vertical paper tape filter 10, embedded liquid cooler 2, and recovery coolant storage tank 6 are combined into a chip removal mechanism and a liquid recovery, filtration, cooling and recycling mechanism. There are two connected clean water tanks 16, the sewage tank 17 and the clean water tank 16 are installed side by side with the chip receiving tank 24, and the chip removal machine 7 connected to the chip receiving tank 24 is installed in the chip receiving tank 24 notches. The conveying chain plate 23 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com