Method for mounting deep sea underwater heavy facility by using buoyancy blocks and hoisting and guiding dual-use cable

A buoyancy block and deep-sea technology, applied to cranes and other directions, can solve the problems of insufficient versatility and difficulty in greatly increasing the installation weight, and achieve the effect of reducing the requirement of compensation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

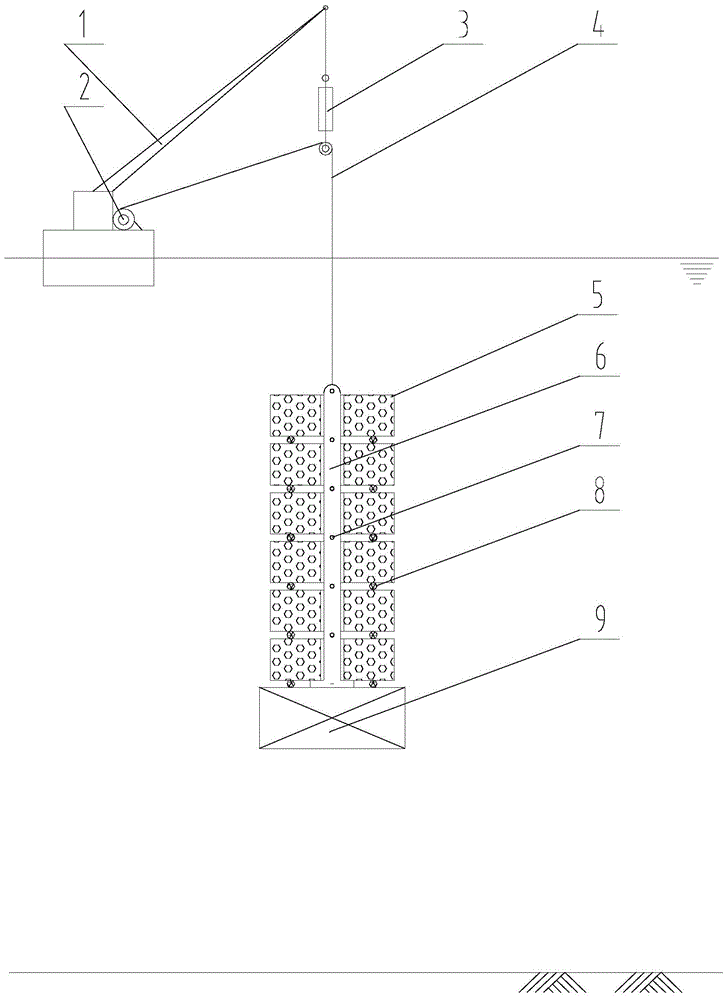

[0043] Example 1: Installation of joint module of subsea manifold and oil-gas separation

[0044] The water depth of the target area is 3000m. The self-weight of the module and accessories is 1321t, and the underwater self-weight is 1081t. Each deep sea buoyancy block used is 300m 3, with a dead weight of 201.5t and a remaining buoyancy of 106t, according to the calculation, 10 deep-sea buoyancy blocks are selected. The remaining weight of full immersion is 21t. As the water enters deeper, the remaining buoyancy provided by the deep-sea buoyancy block will decrease, and the remaining weight will increase to 53t. It is hoisted with a single cable with an allowable pulling force of 980KN. Connect all the equipment and components on the large barge with a total weight of 3436t. Use the auxiliary crane with a lifting capacity of 4500t to hoist the complete set of equipment into the water. , to accept 21t load. Remove the sling of the auxiliary crane, retract the winch and low...

Embodiment 2

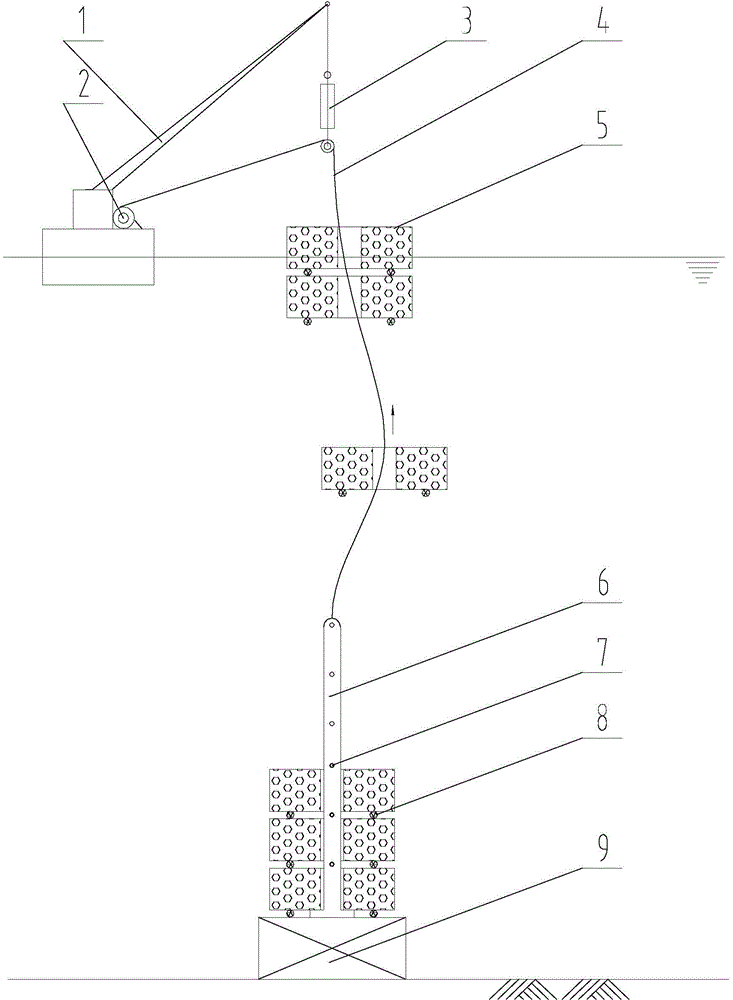

[0045] Example 2: 100000m 3 Underwater tank installation

[0046] The water depth of the target sea area is 1500m. The main body of the storage tank is made of steel, with double walls, double roofs and no bottom. The maximum capacity of the storage tank is 100000m 3 , including the fixed weight of 18577t, the underwater weight of 14596t, and the underwater weight of 15311t after adding other auxiliary installation components; each deep-sea buoyancy block used is 300m 3 , with a dead weight of 201.5t and a remaining buoyancy of 106t, according to calculations, 144 deep-sea buoyancy blocks are selected. The remaining weight of full immersion is 47t. With the deepening of the water, the remaining buoyancy provided by the deep-sea buoyancy block under pressure will decrease, and the remaining weight will increase to 194t. Therefore, it is slightly different from the previous scheme: one is to use a double set of hoisting system, which consists of two Two systems with a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com