Cable penetrating method for single-tower cable hoisting

A cable hoisting and cable threading technology, applied in the cable threading field of cable hoisting, can solve the problems of inability to achieve, uneven tightening degree, and large lifting force of the hoisting rope, so as to ensure the uniformity of force, ensure safety and reliability, The effect of speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

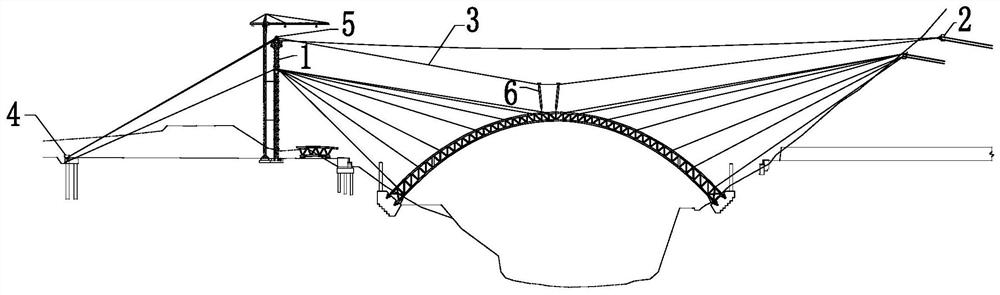

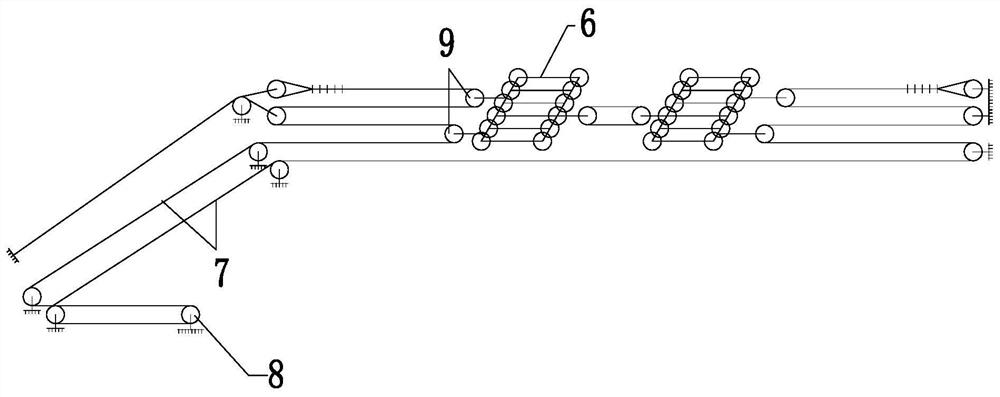

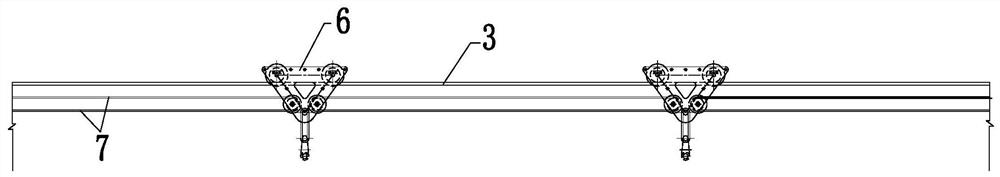

[0031] refer to Figure 1-Figure 5 , the invention provides a single tower cable hoisting method, comprising the following steps:

[0032] 1) Set up the pendant tower 1 on one side of the river bank, and take the guide rope to the opposite bank of the river by ferry;

[0033] 2) Pull the head end of the guide rope to the mountaintop on the opposite bank of the river by the first hoist; the end of the guide rope is connected to the traction rope;

[0034] 3) Utilize the first hoist to continue to pull the guide cable, and after driving the guide cable to cross the river valley, turn the guide cable back to the side of the river bank through the guide cable after passing through the steering wheel of the first ground anchor 2 on the top of the mountain; The rope clip is attached with the main rope 3;

[0035] 4) The traction cable drives the main cable 3 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com