Polythiophene/organic micro-crystal muscovite conductive mineral material and preparing method thereof

A technology for microcrystalline muscovite and mineral materials, applied in the field of functional mineral materials, can solve the problems of toxic organic solvents, decreased material conductivity, personnel and air pollution, etc., and achieves mild implementation conditions, improved material conductivity, and increased interlayer spacing. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of polythiophene / organic microcrystalline muscovite conductive mineral material of the present invention comprises the steps:

[0041] a. Dissolve 6-10 parts by weight of organic microcrystalline muscovite and 1-5 parts by weight of emulsifier in water, and stir at a constant temperature of 55-65°C to obtain a milky dispersion solution;

[0042] b. Add 3 to 30 parts by weight of thiophene to the milky dispersion solution and stir;

[0043] c. Cool down to 15-25°C and continue stirring;

[0044] d. Add 0.15 to 0.7 parts by weight of ferric chloride hexahydrate, stir and fully react;

[0045] f. Add 1 to 8 parts by weight of calcium chloride, break the emulsion with ethanol, let it stand for discharging, filter and wash;

[0046] g. Vacuum drying at 60-70°C to constant weight, grinding and refining to obtain the polythiophene / organic microcrystalline muscovite conductive mineral material.

[0047] Further, as a more preferred technical solution, ...

Embodiment 1

[0073] a, Weigh 20.0002g microcrystalline muscovite, add to 100ml6mol / L of HN0 3 In the solution, stir at a constant temperature of 85°C for 6h, let it stand for cooling and filter, filter and wash several times, vacuum-dry at 60°C, and grind to obtain acidified microcrystalline muscovite (K1).

[0074] b. Weigh 15.004g of the above K1, 90.120g of LiNO 3 Grind and mix evenly, place in a tube furnace at 400°C for 5 hours, let stand to cool, wash and filter several times, vacuum-dry at 60°C, and grind to obtain Lithified microcrystalline muscovite (K2).

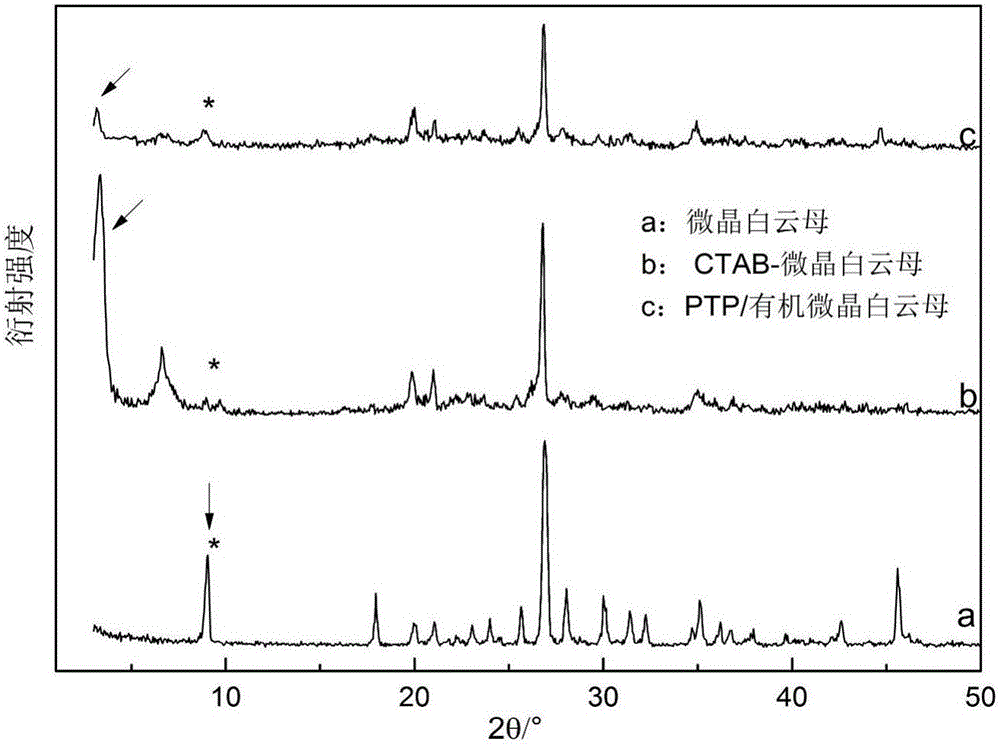

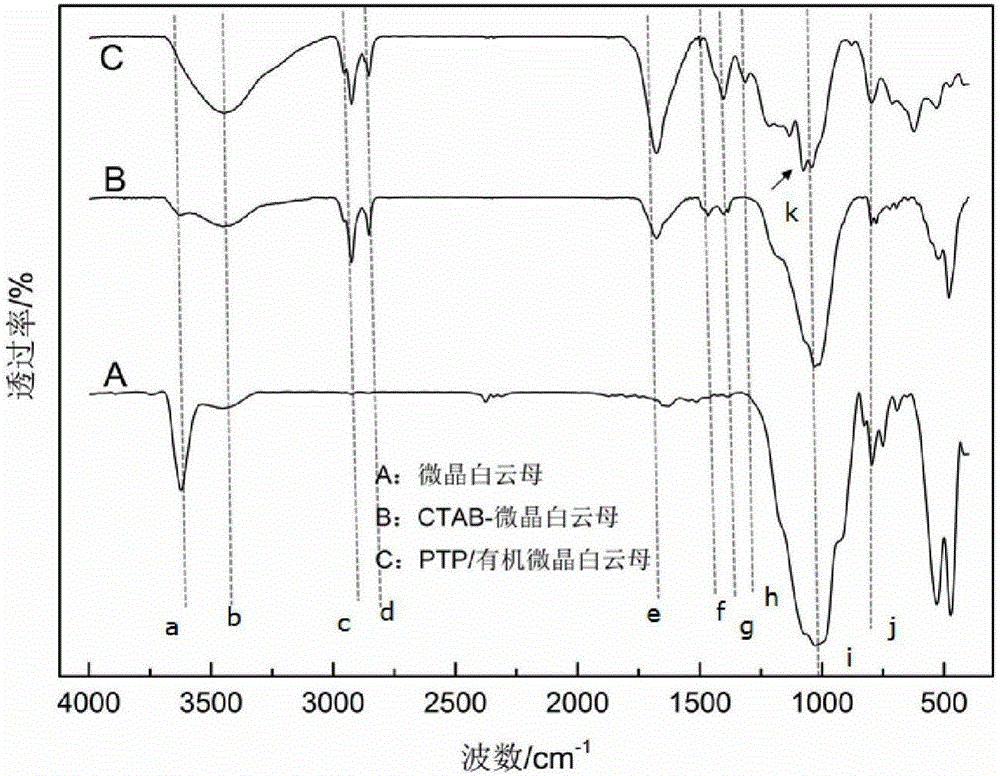

[0075] c. Weigh 3.004g of the above-mentioned K2 and dissolve it in an appropriate amount of deionized water, add 0.4387g of hexadecyltrimethylammonium bromide, stir at a constant temperature of 80°C for 6h, let it stand for cooling, wash and filter several times until there is no Br - (0.1mol / LAgNO 3 Solution detection, until there is no white precipitate), take it out and grind it to obtain the modified organic microcrystal...

Embodiment 2

[0079] a. Weigh 3.002 g of microcrystalline muscovite after ligation in Example 1 and dissolve it in an appropriate amount of deionized water, add 1.231 g of hexadecyltrimethylammonium bromide, stir at a constant temperature of 80° C. for 6 h, let it stand for cooling, and then Wash and filter until no Br - (0.1mol / LAgNO 3 Solution detection, until there is no white precipitate), take it out and grind it, which is the modified organic microcrystalline muscovite.

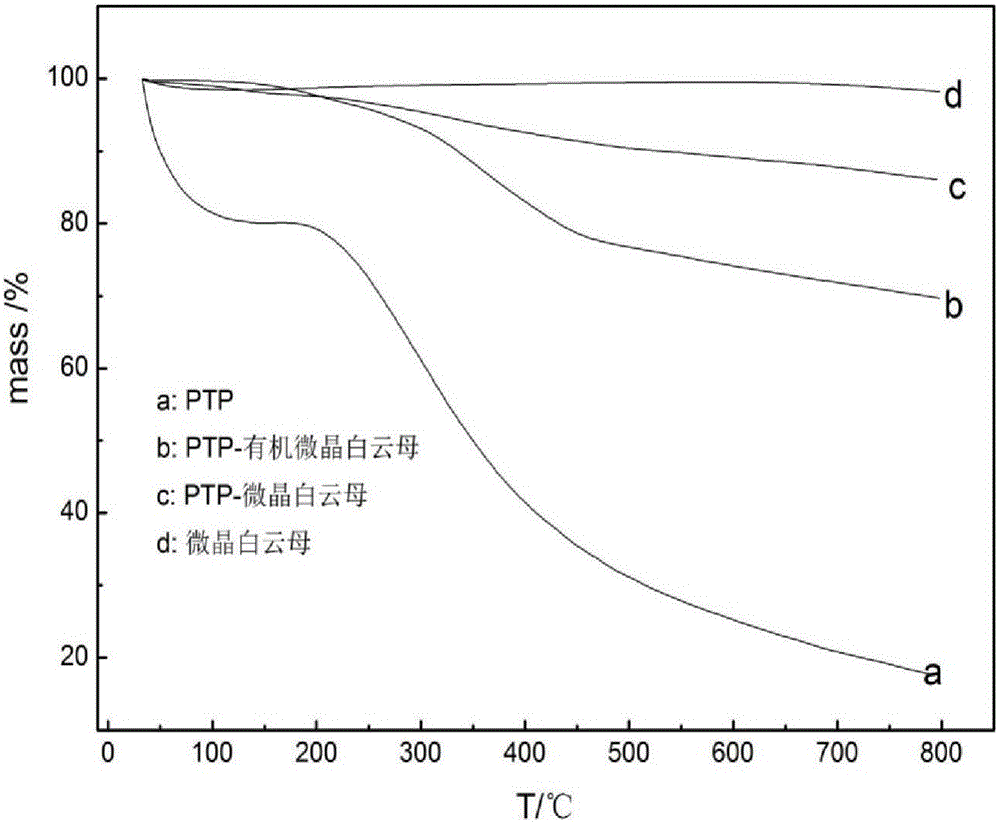

[0080] b. Weigh 0.9008g of the organic microcrystalline muscovite obtained in the above step a and dissolve it in 40ml of deionized water, add 0.1805g of SDBS, stir vigorously at 60°C for 1h, pipette 0.45mlTP into the reaction solution, and continue stirring vigorously for 2h; cool down to room temperature, weigh 0.0214gFeCl 3 ·6H 2 O was dissolved in 5ml deionized water, and FeCl was slowly added dropwise 3 Solution, continue to react for 12 hours; stop stirring, add 25ml of absolute ethanol, 0.3134g of anhydrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com