A Hybrid Steel Structure Grid Cooling Tower

A technology of steel grids and cooling towers, applied in arched structures, dome structures, refrigeration plants, etc., can solve the problem of poor design economy, difficulty in adapting to the needs of super-large cooling towers, and reduced lateral stiffness and bearing capacity issues such as low construction cost, improved integration and material usage efficiency, and little influence of seasonal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

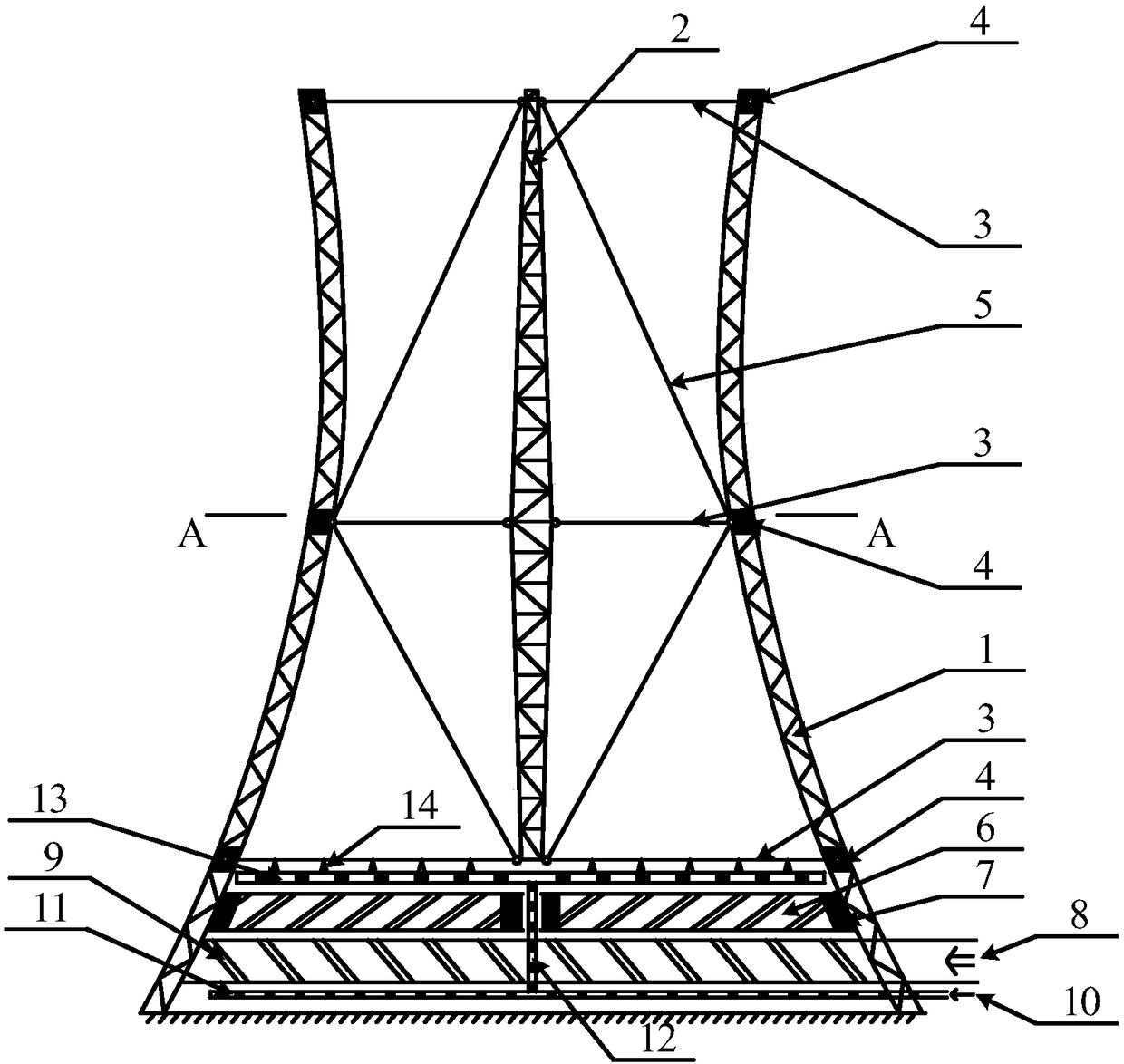

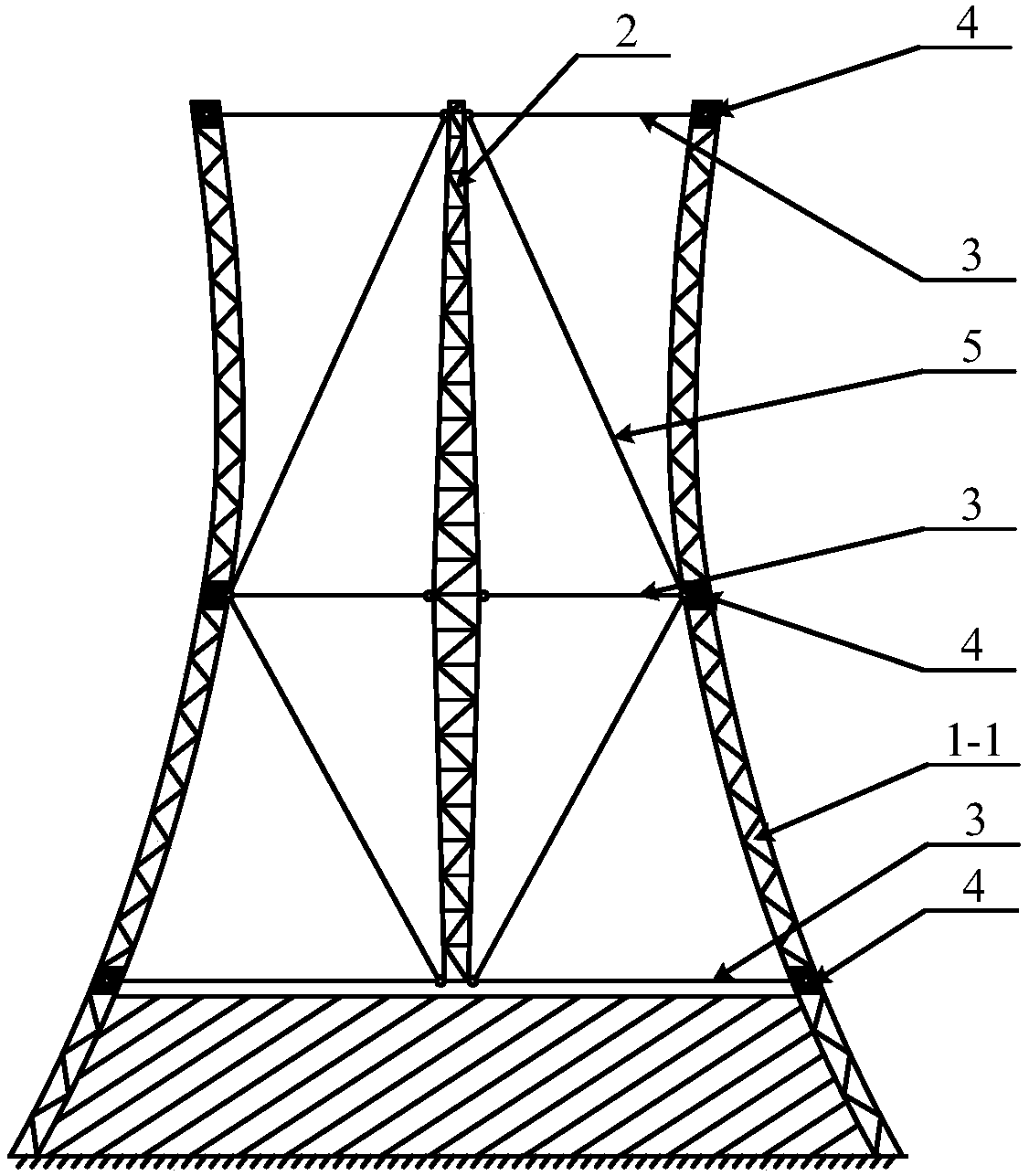

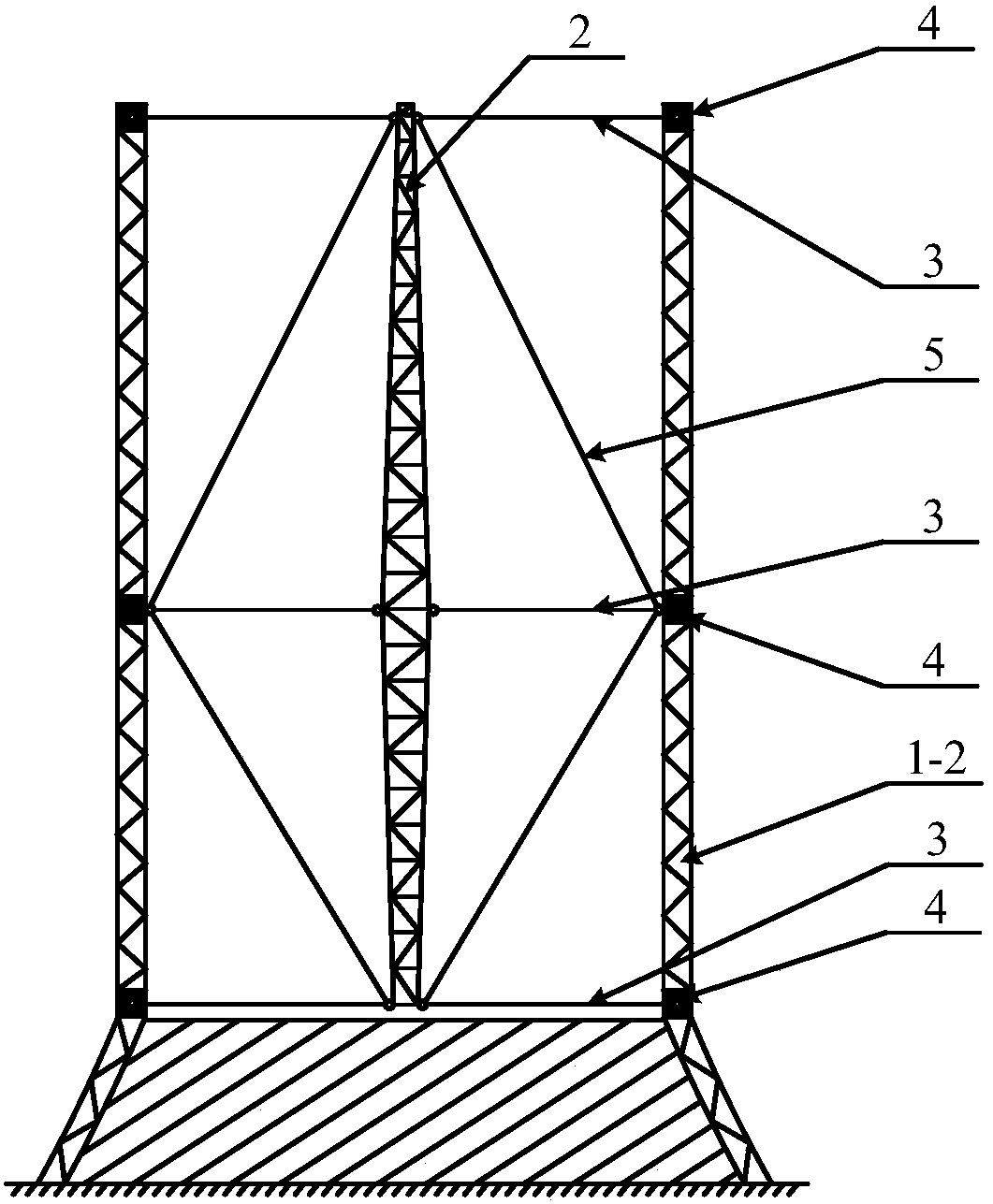

[0023] Attached below Figure 1~4 , to describe the implementation of the present invention in detail.

[0024] like Figure 1~4 As shown, a hybrid steel grid cooling tower includes the following components:

[0025] 1——Steel lattice shell, including two types: 1-1——hyperboloid steel lattice shell, 1-2——cylindrical frustum steel lattice shell;

[0026] 2——Middle support truss fly column;

[0027] 3——Prestressed cable reel, including two types: 3-1——Single-layer plane cable reel, 3-2——Spoke space cable reel;

[0028] 4—Peripheral ring truss;

[0029] 5—Spatial oblique radiation prestressed cables;

[0030] 6—Stacking area;

[0031] 7 - thermal insulation layer;

[0032] 8 - cooling water inlet;

[0033] 9——Collective pool;

[0034] 10 - shaft;

[0035] 11——Water spray pipe network;

[0036] 12 - hanger;

[0037] 13 - air inlet;

[0038] 14—Condensation zone.

[0039] like figure 1 As shown, the hybrid steel structure grid cooling tower includes load-bearing struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com