Bearing heat radiation remote monitoring system

A technology of remote monitoring system and control system, applied in the field of bearing heat dissipation, can solve the problems of inability to achieve bearing heat dissipation, uneven cooling, and low heat generation, so as to achieve the effect of no need for frequent maintenance, no cooling dead angle, and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

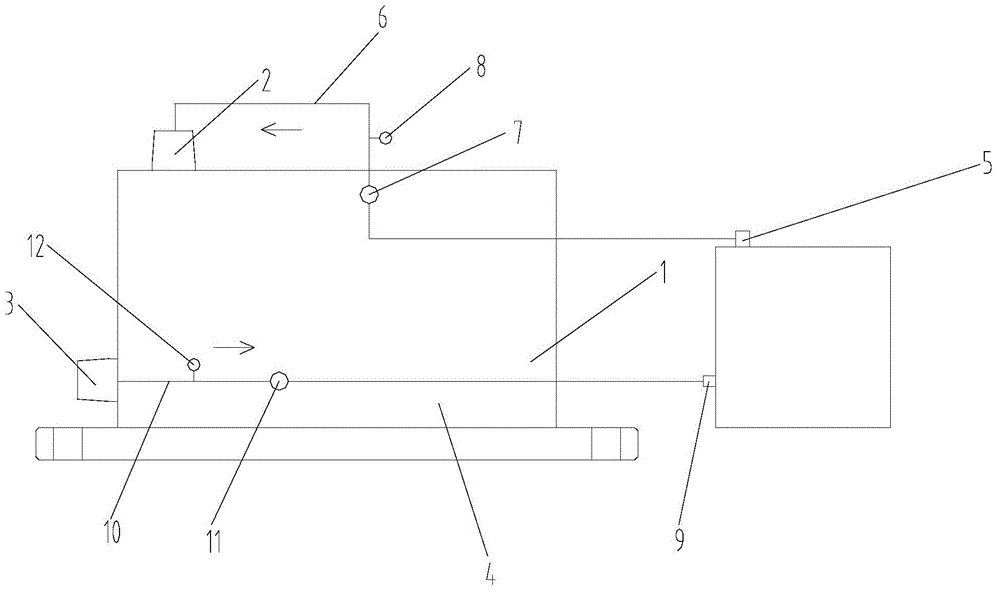

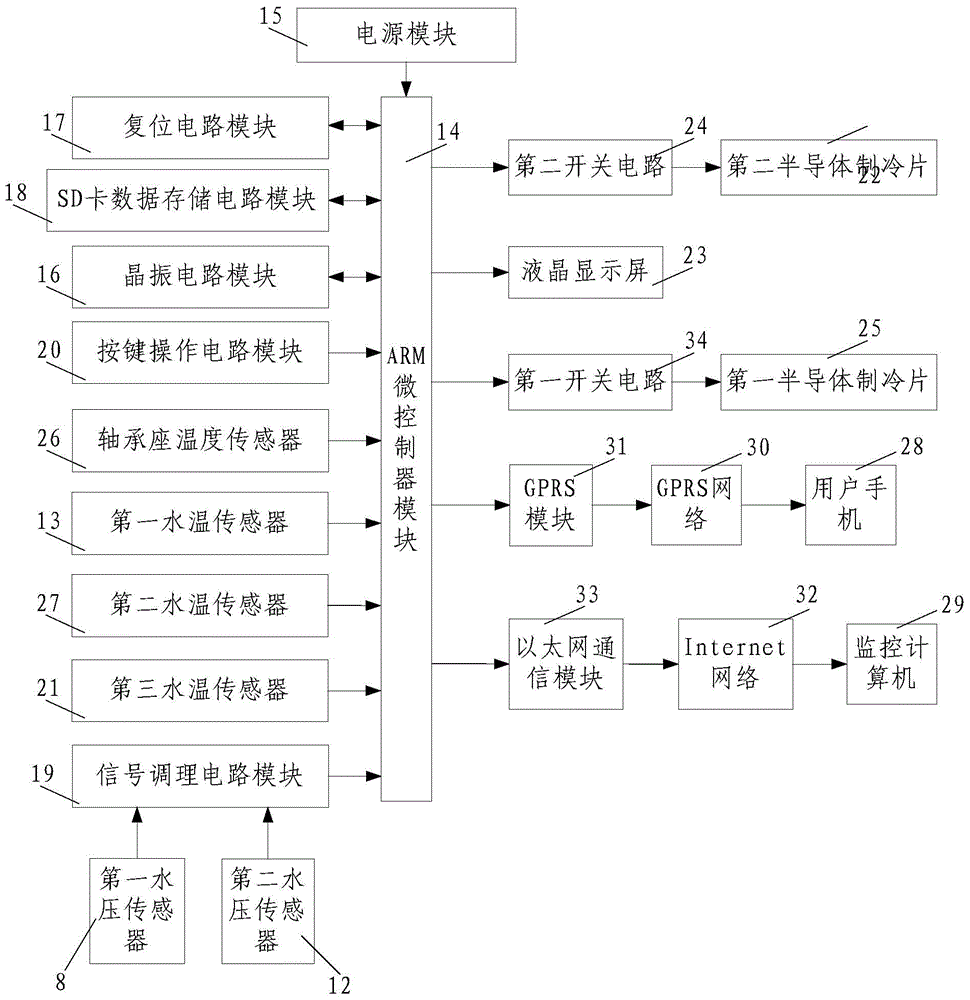

[0033] Such as figure 1 and figure 2As shown, the present invention includes a water-cooled bearing seat for installing a bearing, a cooling water circulation system for supplying cooling water to the water-cooled bearing seat, and a heat dissipation control system for monitoring the heat dissipation process of the bearing. The water-cooled bearing The seat includes a bearing seat body 1 and a water-cooling cavity arranged inside the bearing seat body 1. The shape of the water-cooling cavity is bow-shaped. The water cooling chamber water inlet 2, the other end of the water cooling chamber is the water cooling chamber water outlet 3 located at the lower part of the bearing seat body 1, the inside of the water cooling chamber is uniformly provided with a plurality of installation grooves, each of the The installation grooves are all installed with the first semiconductor refrigeration sheet 25 for cooling the circulating water inside the water-cooling cavity, and the top of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com