Conditioning Agents for Improving Low Temperature Resistance of Wheat

A conditioner and low-temperature resistance technology, applied in the directions of plant growth regulators, plant growth regulators, biocides, etc., can solve the problems of poor resistance of wheat to cold damage, failure to significantly prevent and reduce disasters, etc., and improve the quality of wheat. , the effect of promoting wheat tillering and promoting the growth and development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

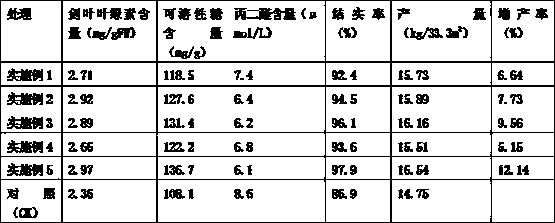

Image

Examples

Embodiment 1

[0030] Embodiment 1: according to the following steps, prepare the conditioning agent for improving wheat low temperature resistance

[0031] (1) Take the following components in parts by weight: 5 parts of 6-BA powder with a mass concentration of 98%, 15 parts of naphthalene acetate powder with a mass concentration of 70%, 20 parts of methylpiperium powder with a mass concentration of 96%, and 40 parts of a mass concentration 20 parts of %ethephon liquid, 20 parts of potassium dihydrogen phosphate powder with a mass concentration of 98%;

[0032] (2) Dissolve 6-BA in alcohol, the dissolution ratio is 1g mass concentration 98% 6-BA dissolved in 5ml water;

[0033] (3) Dissolve 70% naphthalene acetate in mass concentration in water, and the dissolution ratio is 1g of 70% mass concentration of naphthalene acetate powder in 50ml of water;

[0034] (4) Add mass concentration 98% potassium dihydrogen phosphate powder to the mixture in step (3), and fully stir and dissolve;

[003...

Embodiment 2

[0040] Embodiment 2: according to the following steps, prepare the conditioning agent for improving wheat low temperature resistance

[0041] (1) Take the following components in parts by weight: 10 parts of 6-BA powder with a mass concentration of 98%, 10 parts of naphthalene acetate powder with a mass concentration of 70%, 30 parts of methylpiperium powder with a mass concentration of 96%, and 40 parts of a mass concentration 10 parts of %ethephon liquid, 20 parts of potassium dihydrogen phosphate powder with a mass concentration of 98%;

[0042] (2) Dissolve 6-BA in alcohol, the dissolution ratio is 1g mass concentration 98% 6-BA dissolved in 5ml water;

[0043] (3) Dissolve 70% naphthalene acetate in mass concentration in water, and the dissolution ratio is 1g of 70% mass concentration of naphthalene acetate powder in 50ml of water;

[0044] (4) Add mass concentration 98% potassium dihydrogen phosphate powder to the mixture in step (3), and fully stir and dissolve;

[0045...

Embodiment 3

[0050] Embodiment 3: according to the following steps, prepare the conditioning agent for improving wheat low temperature resistance

[0051] (1) Take the following components in parts by weight: 10 parts of 6-BA powder with a mass concentration of 98%, 15 parts of naphthalene acetate powder with a mass concentration of 70%, 20 parts of methylpiperium powder with a mass concentration of 96%, and 40 parts of a mass concentration 20 parts of %ethephon liquid, 30 parts of potassium dihydrogen phosphate powder with a mass concentration of 98%;

[0052] (2) Dissolve 6-BA in alcohol, the dissolution ratio is 1g mass concentration 98% 6-BA dissolved in 5ml water;

[0053] (3) Dissolve 70% naphthalene acetate in mass concentration in water, and the dissolution ratio is 1g of 70% mass concentration of naphthalene acetate powder in 50ml of water;

[0054] (4) Add mass concentration 98% potassium dihydrogen phosphate powder to the mixture in step (3), and fully stir and dissolve;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com