Vitamin A and mineral enriched nutritional dried meat floss and preparation method thereof

A technology of mineral and meat floss, applied in the field of nutritional meat floss rich in vitamin A and minerals and its preparation, can solve the problems of long time and singleness, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

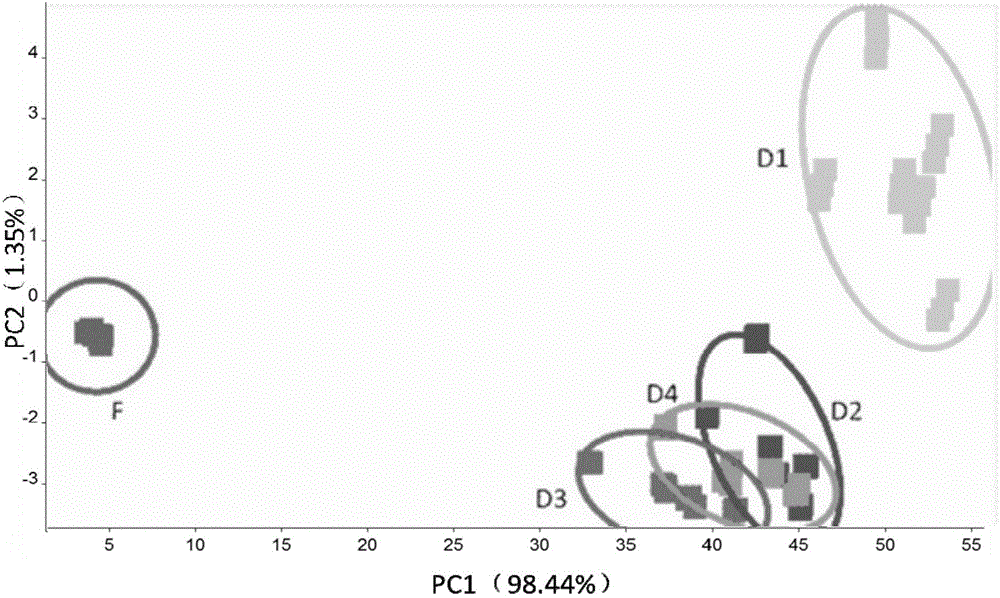

Image

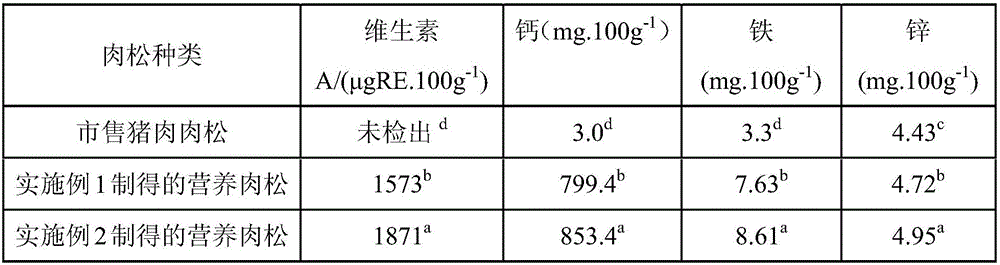

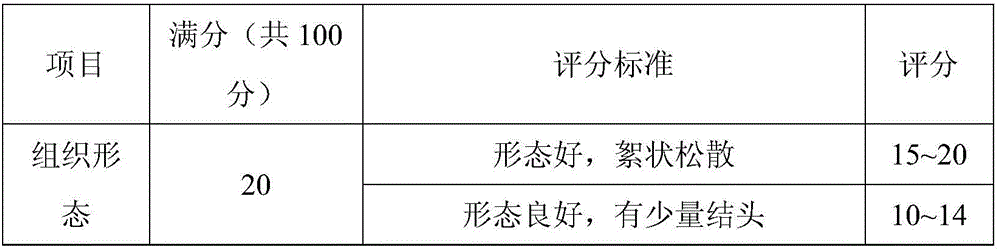

Examples

Embodiment 1

[0031] (1) Raw meat pretreatment

[0032] Clean the hind legs of pigs that have passed the hygienic inspection and have a lot of fresh lean meat, and remove the bones, skin, fat and tendons to obtain lean meat, and cut the lean meat along the fibers into cubes with a length and width of 3 cm;

[0033] (2) Preparation of fermented pig liver puree

[0034] Rinse the fresh pork liver under tap water and put it into a tissue grinder. First, grind it at 2000r / min for 10 minutes until there is no lump, and then grind it at 12000r / min for 8 minutes to form a puree. Put the pig liver into the ultrasonic cell breaker, and perform ultrasonic crushing treatment at 500W. The specific crushing process is ultrasonic treatment for 1s, intermittent for 1s, and then ultrasonic treatment for 1s, intermittent for 1s, and continue to operate according to the above ultrasonic treatment time and intermittent time. When the sum of the ultrasonic treatment time and the intermittent time reaches 20 m...

Embodiment 2

[0042] (1) Raw meat pretreatment

[0043] Clean the pork hind legs that have passed the hygienic inspection and have a lot of fresh lean meat, and remove the bones, skin, fat and tendons to obtain lean meat, and cut the lean meat along the fiber into cubes with a length and width of 4 cm;

[0044] (2) Preparation of fermented pig liver puree

[0045] Rinse the fresh pork liver under tap water and put it into a tissue masher, first mash it at 5000r / min for 5 minutes until there is no lump, and then mash it at 10000r / min for 10 minutes to become a puree. Put the pig liver into the ultrasonic cell breaker, and ultrasonically crush it at 200W. The specific crushing process is ultrasonic treatment for 5s, intermittent for 5s, and then ultrasonic treatment for 5s, intermittent for 5s. Continue to operate according to the above ultrasonic treatment time and intermittent time. When the sum of the ultrasonic treatment time and the intermittent time reaches 40 minutes, the treatment is...

Embodiment 3

[0053] (1) Raw meat pretreatment

[0054] Clean the haunches of rabbits that have passed the hygienic inspection and have a lot of fresh lean meat, and remove the bones, skin, fat and tendons to obtain lean meat, and cut the lean meat along the fibers into cubes with a length and width of 5 cm;

[0055] (2) Preparation of fermented pig liver puree

[0056] Rinse the fresh pork liver under tap water and put it into a tissue grinder. First, grind it at 3000r / min for 8 minutes until there is no lump, and then grind it at 11000r / min for 9 minutes to form a puree. Put the pig liver into the ultrasonic cell breaker, and perform ultrasonic crushing treatment at 400W. The specific crushing process is ultrasonic treatment for 4s, intermittent 4s, and then ultrasonic treatment for 4s, intermittent 4s. Continue to operate according to the above ultrasonic treatment time and intermittent time. When the sum of the ultrasonic treatment time and the intermittent time reaches 30 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com