Method for reinforcing copper-nickel sulphide ore flotation separation in industrialized application

A copper-nickel sulfide ore and flotation technology, applied in flotation, solid separation and other directions, can solve the problems of seldom industrial application, unclear relationship between process parameters, and difficult to define the conditions of mechanical stirring process parameters, so as to eliminate adverse effects. , Simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

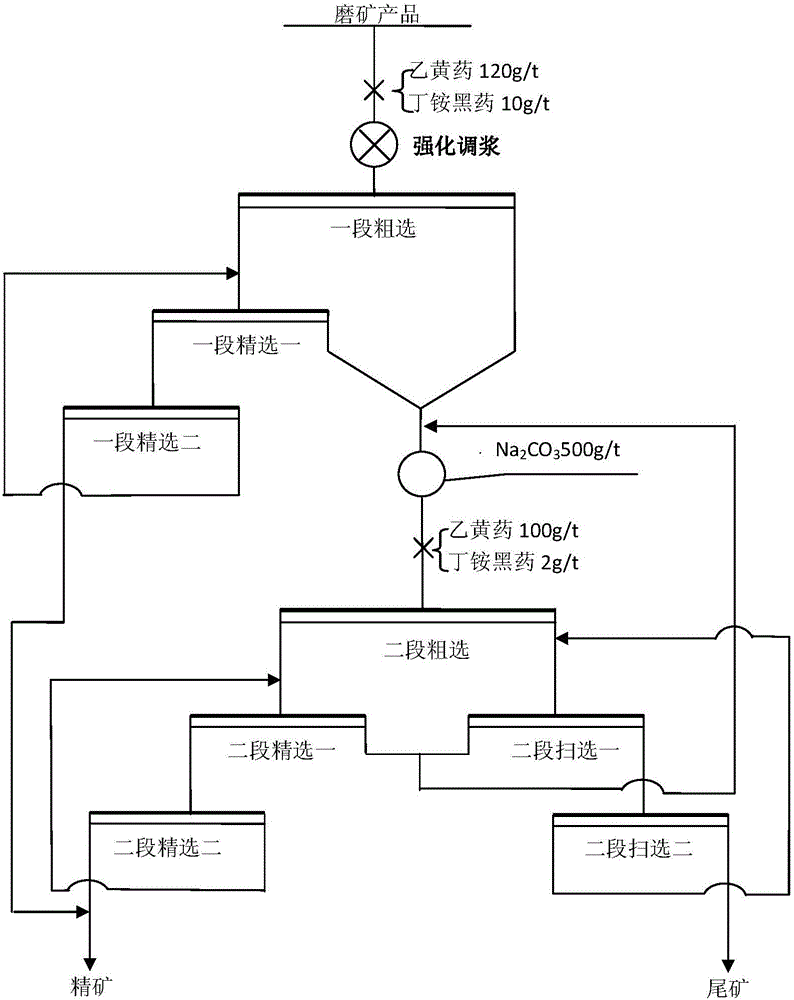

[0022] Refer to the attached figure 1 , to describe Embodiment 1 of the present invention in detail.

[0023] Use manual attached figure 1 The test process is to select a copper-nickel sulfide ore slurry sample, and the slurry processing capacity is 300m 3 / h, the grinding fineness of the selected ore pulp is -0.074mm, accounting for 60-75%, the product of the first stage of grinding is strengthened by mechanical pulping, and the energy input of stirring and pulping is 1.5kW·h / m 3 ~0.8kW·h / m 3 Within the range, the linear velocity of the tip of the stirring impeller is in the range of 7.5m / s~10.0m / s; the slurry after pulping immediately enters the first stage of flotation cycle to obtain the first stage of concentrate, and the first stage of tailings enters the second stage of grinding to obtain the second stage Concentrate and final tailings, the mineral processing indicators obtained are shown in Table 1.

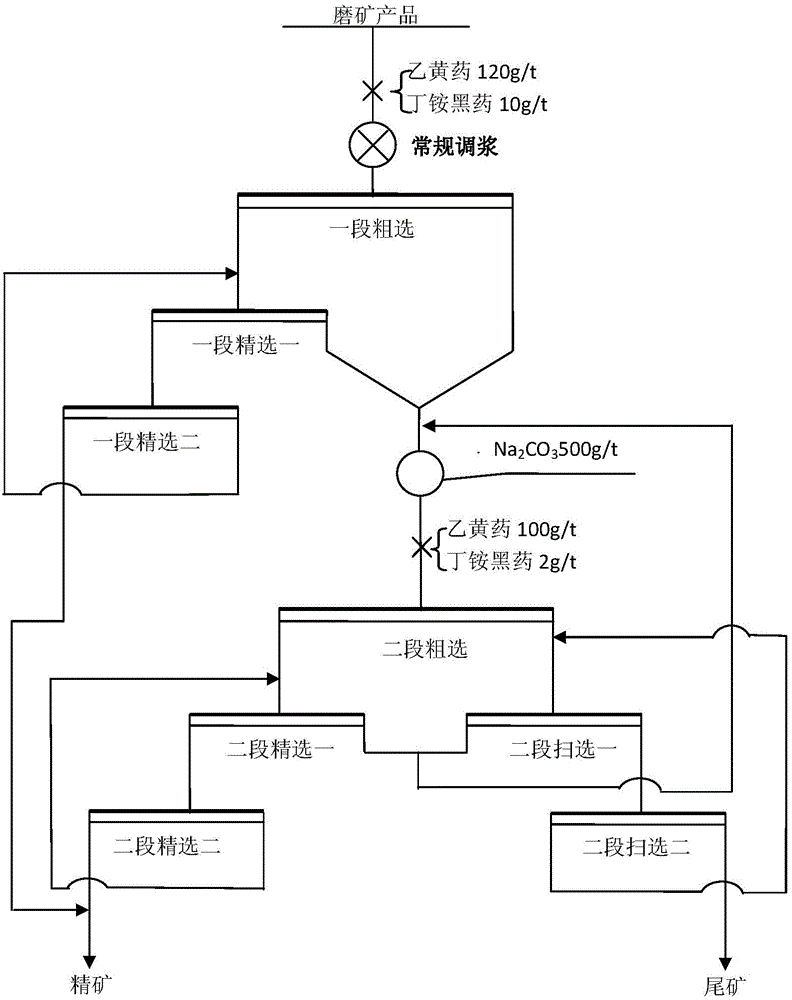

[0024] With conventional copper sulfide nickel ore flotation sch...

Embodiment 2

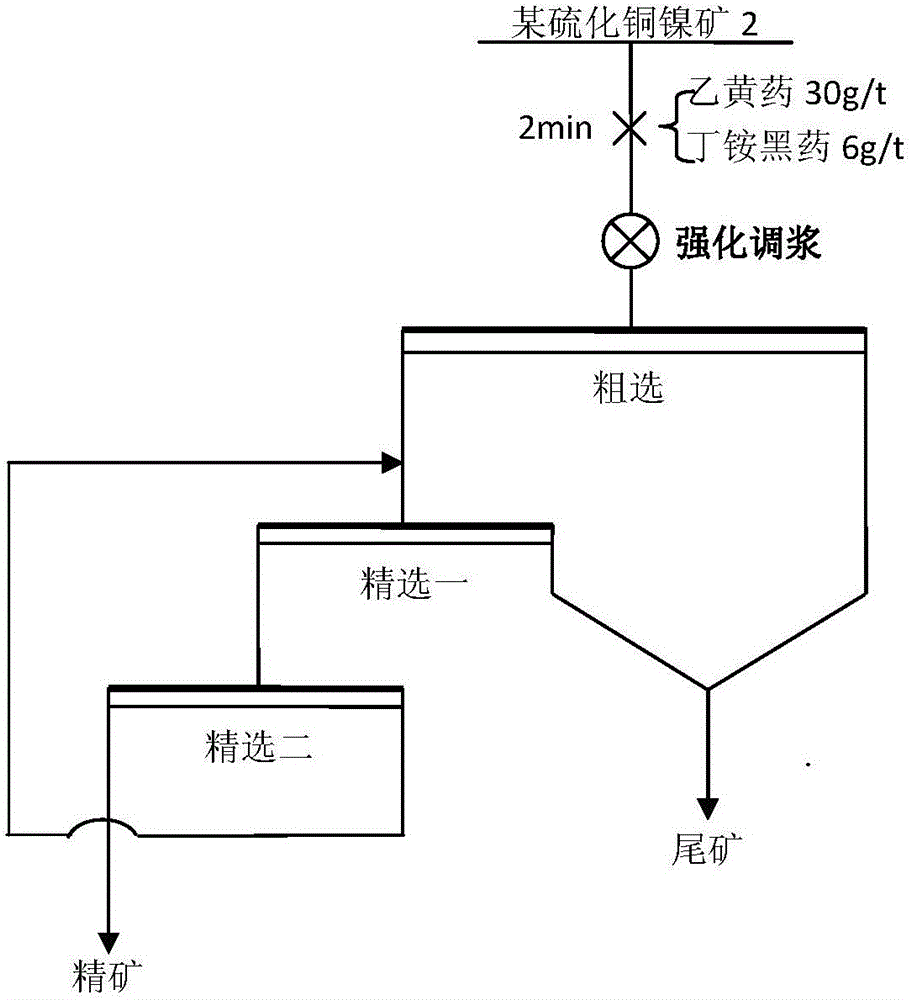

[0029] Refer to the attached image 3 with attached Figure 4 , to describe Embodiment 2 of the present invention in detail.

[0030] Use manual attached image 3 According to the test procedure, the slurry sample 2 of a copper-nickel sulfide ore is selected, and the slurry processing capacity is 15m 3 / h, the grinding fineness of the selected ore pulp is -0.074mm, accounting for 70%, the product of the grinding is strengthened by mechanical pulping, and the energy input of stirring and pulping is 2.5kW·h / m 3 ~1.5kW·h / m 3 Within the range, the linear velocity of the tip of the agitating impeller is in the range of 7.5m / s~10.0m / s, and the ore pulp after slurry adjustment immediately enters the flotation cycle to obtain the final concentrate and flotation tailings. The obtained mineral processing indicators are shown in Table 2 .

comparative approach 1

[0031] Contrast scheme 1: with the comparative copper sulfide nickel ore flotation scheme (parameters of mechanical agitation in the comparative scheme: energy input at 2.7kW h / m 3 , the linear speed of the tip of the stirring impeller is 10.5m / s) to select the same raw materials, the obtained mineral processing index is shown in Table 2, and the test process, process and chemical conditions are shown in the appendix Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com