Control device, equipment and method for controlling electrohydrodynamics printing resolution

A control device and dynamics technology, applied in the direction of improvement of process efficiency, additive manufacturing, energy efficiency, etc., can solve the printing limitation of high resolution, the resolution is difficult to be further improved, and the electrohydrodynamic printing technology is difficult to meet High-resolution micro-nano device printing requirements and other issues, to achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

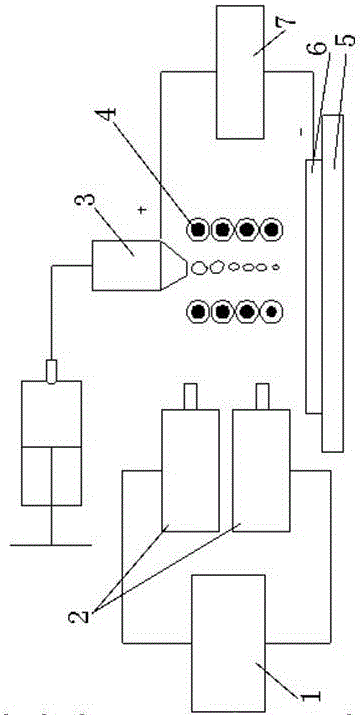

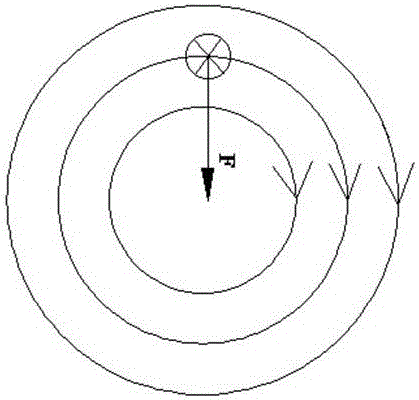

[0026] The present invention provides: a control device for controlling the resolution of electrohydrodynamic printing, which includes a magnetic field generating device 4 for generating centripetal Lorentz force, and a magnetic field generating device 4 connected with the magnetic field generating device 4 for adjusting the centripetal Lorentz force A controller 1 of the magnitude of the force, the controller 1 is connected with two visual detection devices 2, and the visual detection device 2, the controller 1 and the magnetic field generator 4 form a closed-loop control loop.

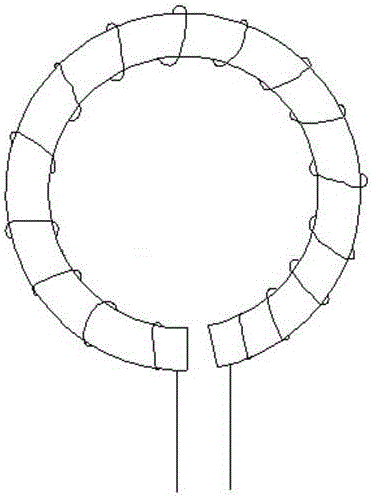

[0027] The magnetic field generating device 4 is composed of at least one annular electromagnetic induction coil wound on the annular iron core, a plurality of annular iron cores are stacked, and each annular iron core is wound with an annular electromagnetic induction coil respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com