A multi-station crystal bar single-wire cutting machine

A crystal rod, multi-station technology, used in metal processing, work accessories, manufacturing tools, etc., can solve the problems of silicon rod material waste, harsh cutting process environment, consumption of manpower and financial resources, etc., to reduce raw material waste, reduce The effect of cutting wire volume and cutting cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

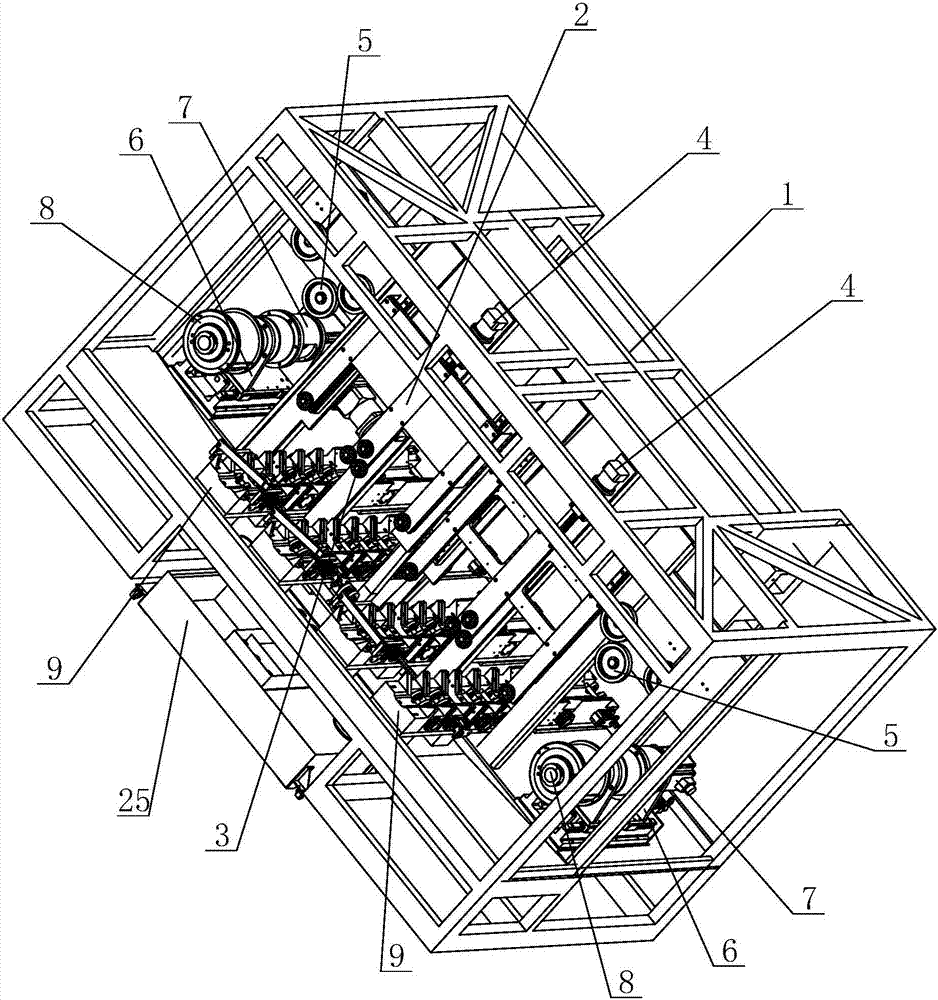

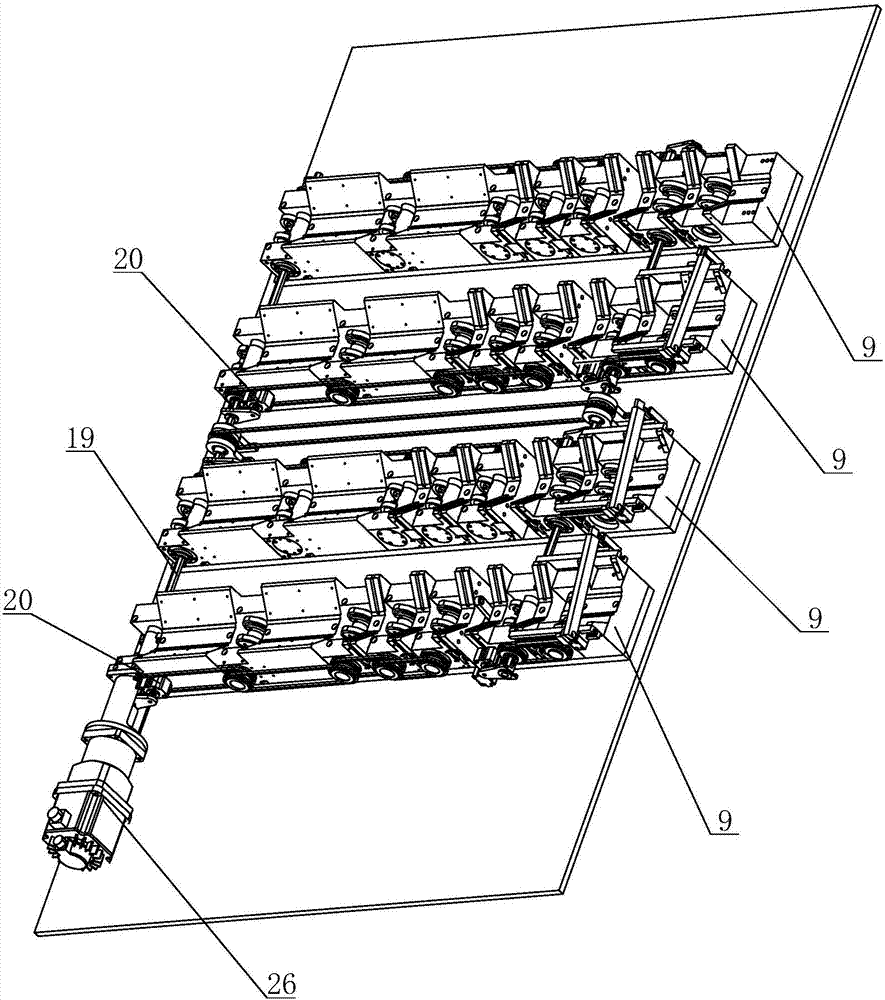

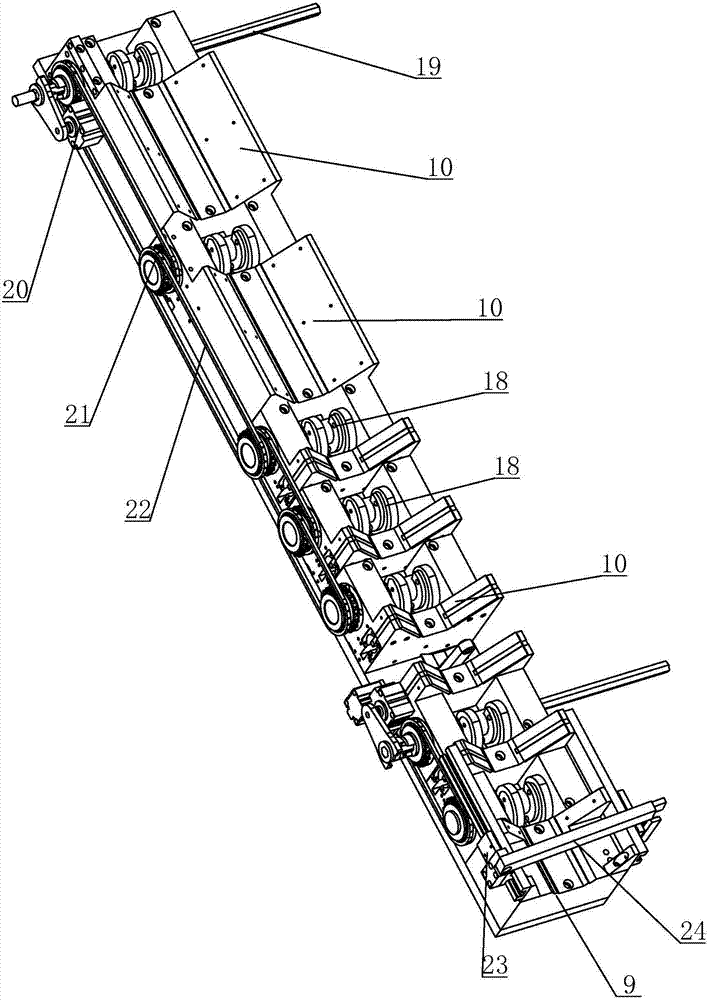

[0028] see Figure 1 to Figure 5 As shown, in this embodiment, a multi-station crystal bar single-wire cutting machine includes a frame 1, a cutting control component, a tension control component, a take-up and release line control component, a feeding component and a water storage device, and the cutting control component Set in the middle of the frame 1, it includes a cutting arm 2, a cutting wire wheel 3 and a cutting arm servo motor 4, the cutting wire wheel 3 is arranged on the cutting arm 2, and the cutting arm 2 passes through a linear guide rail The cutting arm servo motor 4 drives the cutting arm 2 to move up and down through a ball screw, so as to realize the up and down movement of the cutting guide wheel 3 installed on the cutting arm 2. Finally realize the up-and-down movement of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com