Wood acetylation and acetate cooperative production method

A technology of acetylation and acetate, which is applied in the field of acetylated wood preparation, can solve the problems of high corrosion resistance, complicated acetylation process, increased energy consumption and cost, etc., achieve the effect of increasing efficiency and reducing consumption, and increase the added value of acetic acid Value, the effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

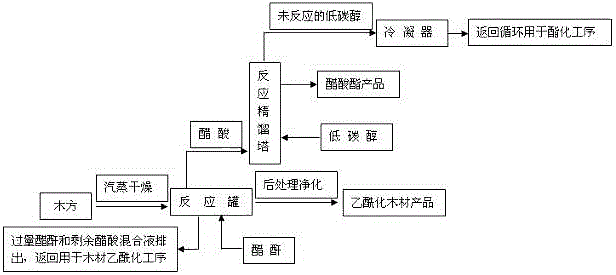

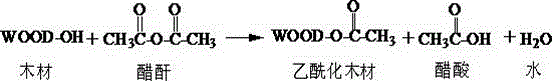

[0024] A method for wood acetylation and co-production of acetate, the preparation steps are as follows: (1) wood drying treatment: first, the wood (length x width x height = 10cm x 10cm x 3m, radiata pine) is steamed and dried until the moisture content is 8%; (2) wood acetylation: put an appropriate amount of wood in the reaction tank, and add acetylation reagent acetic anhydride, so that the wood is completely immersed in acetic anhydride, the volume ratio of wood to acetic anhydride 1:2, then heated to 120°C, the reaction time is 8h, pressurized to 0.5MPa, the wood acetylation reaction; (3) Esterification and co-production of acetate: step (2) by-product acetic acid enters in gas phase At the bottom of the reactive distillation tower, methanol is pumped from the middle and lower part of the reactive distillation tower at the same time, and the SO2 filled in the reactive distillation tower 4 2- / ZrO 2Under the catalysis of a solid superacid catalyst, the esterification re...

Embodiment 2

[0026] A method for wood acetylation and co-production of acetate, the preparation steps are as follows: (1) Wood drying treatment: first, the wood (length x width x height = 10cm x 10cm x 3m, Pinus sylvestris) is steamed, Dry to a moisture content of 10%; (2) Acetylation of wood: put an appropriate amount of wood in a reaction tank, and add acetylation reagent acetic anhydride, so that the wood is completely immersed in acetic anhydride, the volume of wood and acetic anhydride The ratio is 1:2.5, then heated to 130°C, the reaction time is 6h, and the pressure is increased to 0.3MPa to cause the wood to undergo acetylation reaction; (3) Esterification and co-production of acetate: the by-product acetic acid in step (2) is in the form of gas phase Enter the bottom of the reactive distillation tower, and pump ethanol from the middle and lower part of the reactive distillation tower at the same time, and the molecular sieve SO 4 2- Under the catalysis of Zr-ZSM-5 solid superacid...

Embodiment 3

[0028] A method for wood acetylation and co-production of acetate, the preparation steps are as follows: (1) wood drying treatment: first, the wood (length x width x height = 10cm x 10cm x 3m, poplar) is steamed and dried until the moisture content is 12%; (2) wood acetylation: put an appropriate amount of wood in the reaction tank, and add acetylation reagent acetic anhydride, so that the wood is completely immersed in acetic anhydride, the volume ratio of wood to acetic anhydride 1:3, then heated to 140°C, the reaction time is 4h, pressurized to 0.1MPa, so that the wood acetylation reaction; (3) Esterification and co-production of acetate: step (2) by-product acetic acid enters in the form of gas phase At the bottom of the reactive distillation tower, n-butanol is pumped from the middle and lower part of the reactive distillation tower at the same time, and the SO2 filled in the reactive distillation tower 4 2- / TiO 2 Under the catalysis of a solid superacid catalyst, este...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com