Industrial scouring pad manufacturing process and equipment

A production process and technology of scouring pads, which are used in non-woven fabrics, rayon manufacturing, abrasion-resistant fibers, etc., can solve the problems of high cost of adding special fibers, easy waste of solvents, uneven solvent spraying, etc., and improve production. Efficiency, simple equipment, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

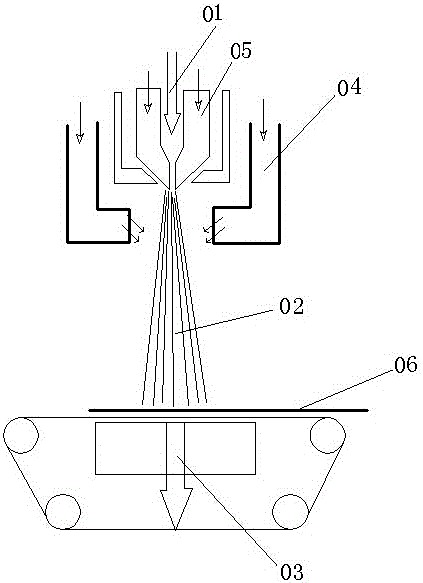

[0022] combine Figure 1-2 , the manufacturing process of a kind of industrial scouring pad of the present invention, comprises the following steps:

[0023] S1: Melting each component polymer 01 through a screw extruder to form a fiber melt 02;

[0024] The components include: 70 parts of polyamide fiber, 30 parts of carbon fiber (PAN), 0.5 part of metal fiber by mass percentage;

[0025] S2: Spray the fiber melt into fiber form through the spinneret hole, and form extremely fine short fiber 03 under the blowing of high-speed (13000m / min) hot air flow;

[0026] S3: short fiber 03 wear resistance spray treatment;

[0027] The abrasion resistance treatment includes: in parts by mass, 50 parts of epoxy resin, 6 parts of curing agent, 20 parts of abrasive, 4 parts of toughening agent, 3 parts of silane coupling agent, and mix uniformly , Spray the short fibers through the spray device.

[0028] S4: Short fibers are adsorbed on the web-forming curtain 06, and the fibers are co...

Embodiment 2

[0034] A manufacturing process of an industrial scouring pad of the present invention comprises the following steps:

[0035] S1: Melting the polymer chips of each component through a screw extruder to form a fiber melt;

[0036] The components include by mass percentage: 80 parts of polyamide fiber, 20 parts of carbon fiber (PAN), 0.5 part of metal fiber;

[0037] S2: Spray the fiber melt into fiber form through the spinneret hole, and form extremely fine short fibers under the blowing of high-speed (13000m / min) hot air;

[0038] S3: short fiber wear resistance spray treatment;

[0039] The abrasion resistance treatment includes: in parts by mass, 50 parts of epoxy resin, 15 parts of curing agent, 20 parts of abrasive, 3 parts of toughening agent, 1 part of silane coupling agent, and mix uniformly , Spray the short fibers through the spray device.

[0040] S4: Short fibers are adsorbed on the web curtain, and the fibers are condensed into industrial scouring pads.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com