3D printer with hook face processing characteristic

A 3D printer, surface processing technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve problems such as gravity limitation, improve printing accuracy and printing efficiency, and avoid uneven top drawing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

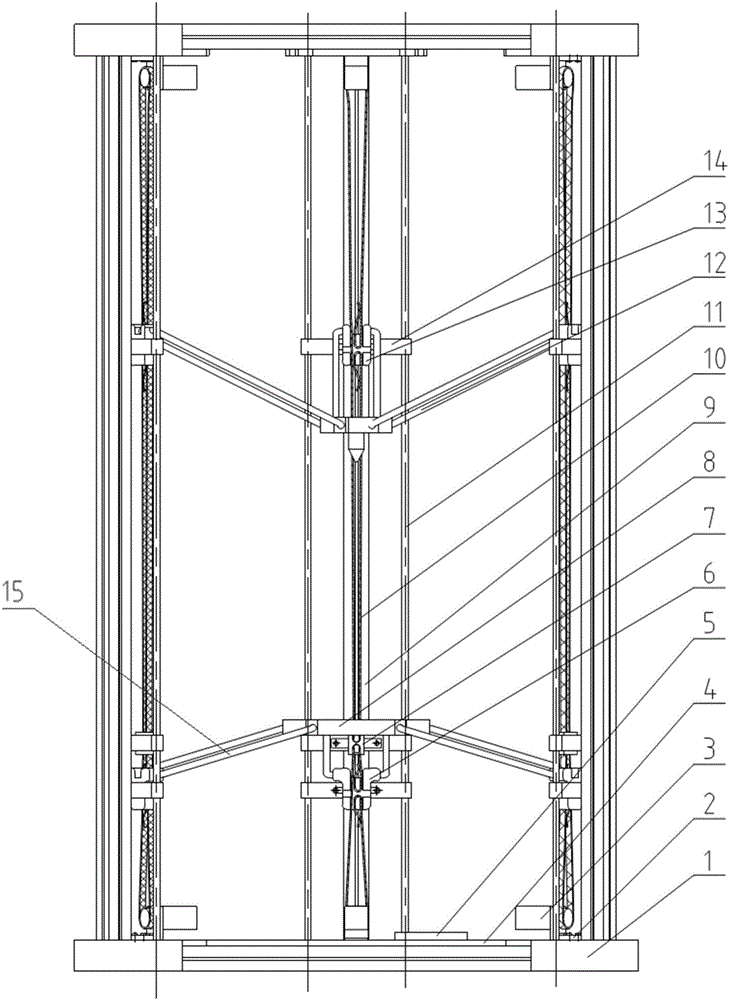

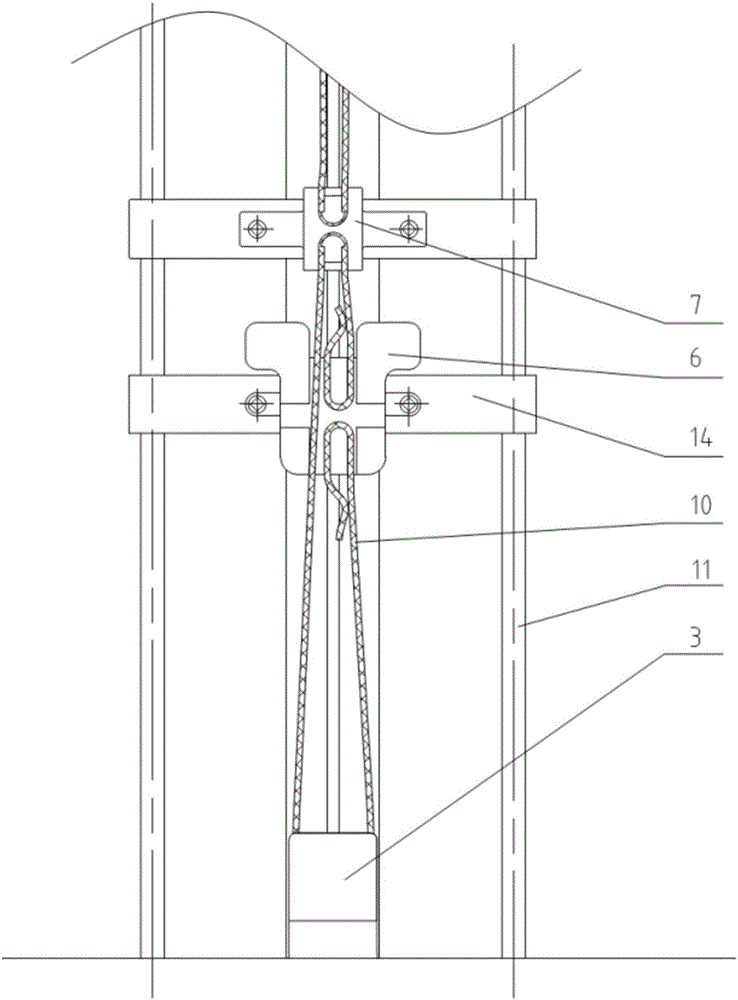

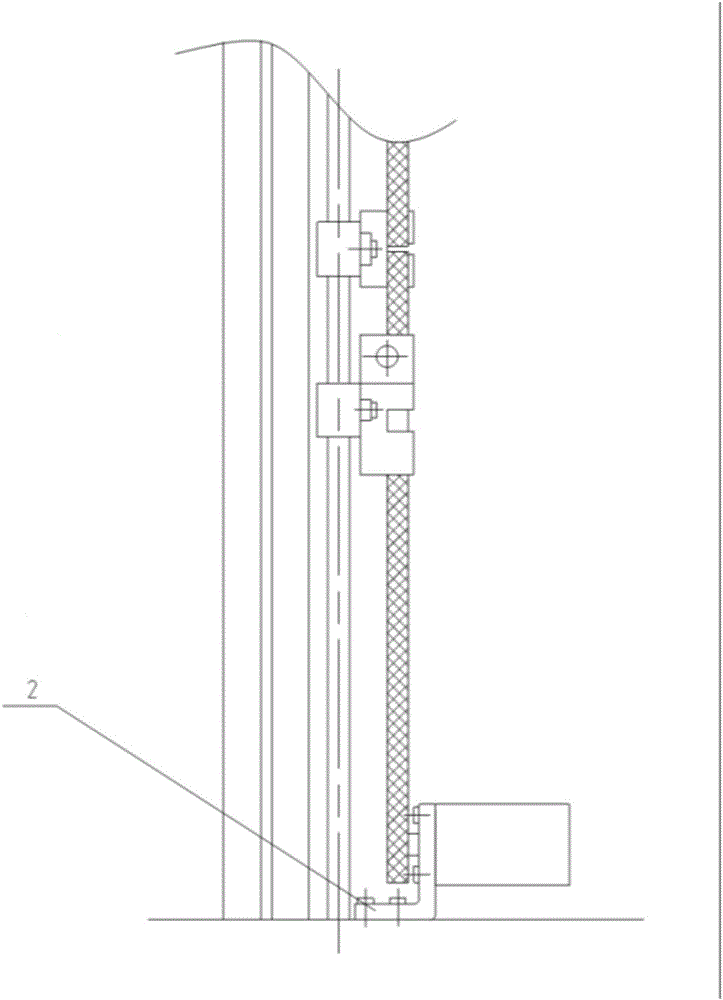

[0027] The overall structure of the present invention is as figure 1 As shown, a 3D printer with curved surface processing characteristics mainly includes a base 1, a motor fixing plate 2, a stepping motor 3, a lower clamp block 6, a stroke stop 7, a working platform 8, a bracket 9, a timing belt 10, a light The bar 11, the first support rod 12, the second support rod 15, the upper clamp block 13, the slider 14, and the nozzle structure.

[0028] The base 1 is a triangle, and the base 1 and the bracket 9 form a triangular prism frame to support the entire system components. The number of bases 1 is two, which are respectively located at the top and the bottom of the frame; six light bars 11 are fixed between the two bases 1 respectively.

[0029] The number of the stepping motors 3 is six, which are respectively fixed on a motor fixing plate 2, and the motor fixing plates 2 are respectively fixed on the base 1 corresponding to the six vertices of the triangular prism frame.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com