Briquetting machine for waste produced in machining

A briquetting machine and machining technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large occupied space, inconvenient transportation, unsightly appearance, etc., achieve small occupied space, improve resource utilization, reduce machine The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

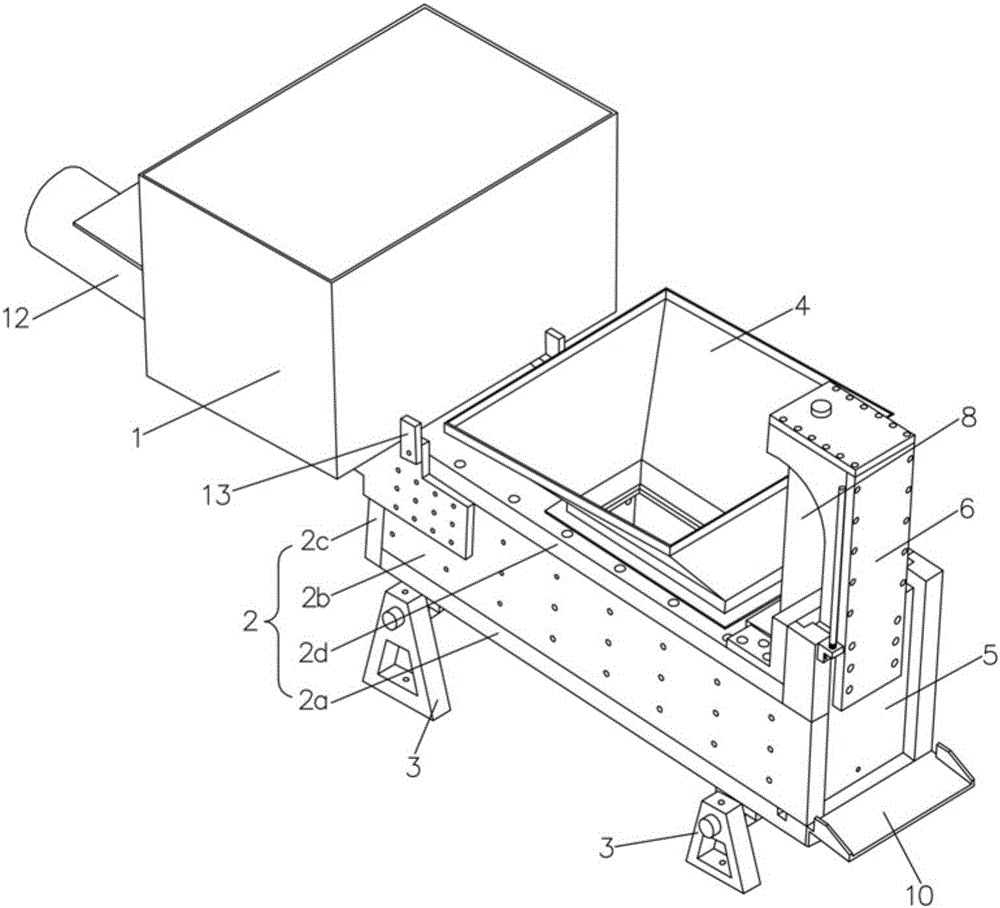

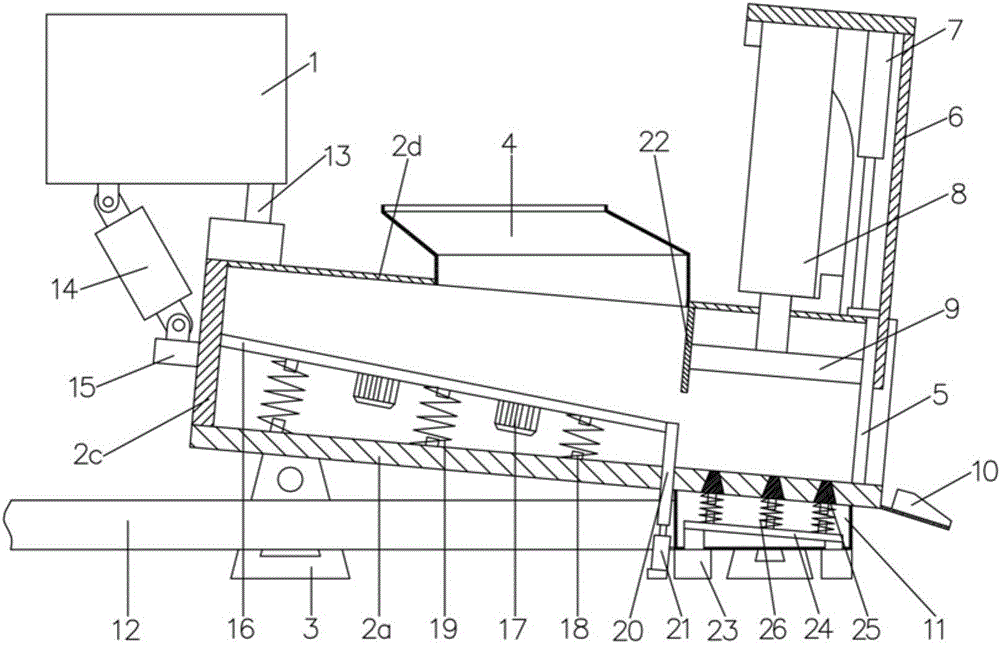

[0020] Example: see Figures 1 to 2 As shown, a machining waste briquetting machine includes a waste hopper 1, and one side of the waste hopper 1 is provided with an inclined rectangular cabinet body 2, and the rectangular cabinet body 2 is composed of a bottom plate 2a, a side plate 2b, a rear panel 2c and a top plate 2d, a number of machine feet 3 are fixed on the lower end surface of the bottom plate 2a, a feed hopper 4 is fixedly connected to the rear end of the top plate 2d; a valve 5 is plugged into the front side of the rectangular cabinet body 2, and the upper end of the valve 5 is fixedly connected to On the piston rod of the lifting cylinder 7, the lifting cylinder 7 is fixed on the oil cylinder fixing bracket 6, and the oil cylinder fixing bracket 6 is fixed on the rectangular cabinet body 2. In the oil cylinder fixing bracket 6, an extrusion cylinder 8 is fixed, and the piston of the extrusion cylinder 8 The rod is fixedly connected with a pressure plate 9, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com