Writing mechanism for writing machine

A writing machine and writing pen technology, applied in the direction of typewriter, printing, etc., can solve the problems of limiting the application field of the inkjet printer, reducing the precision, and expensive consumables, etc., and achieves an enlarged writing range, good continuity and consistency, and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

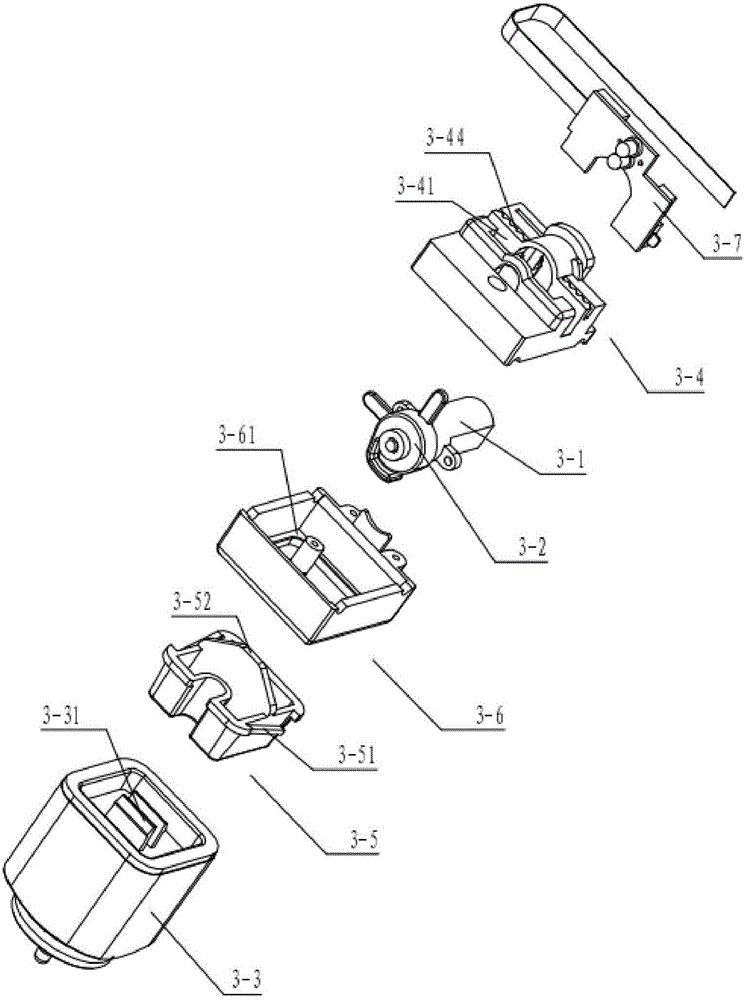

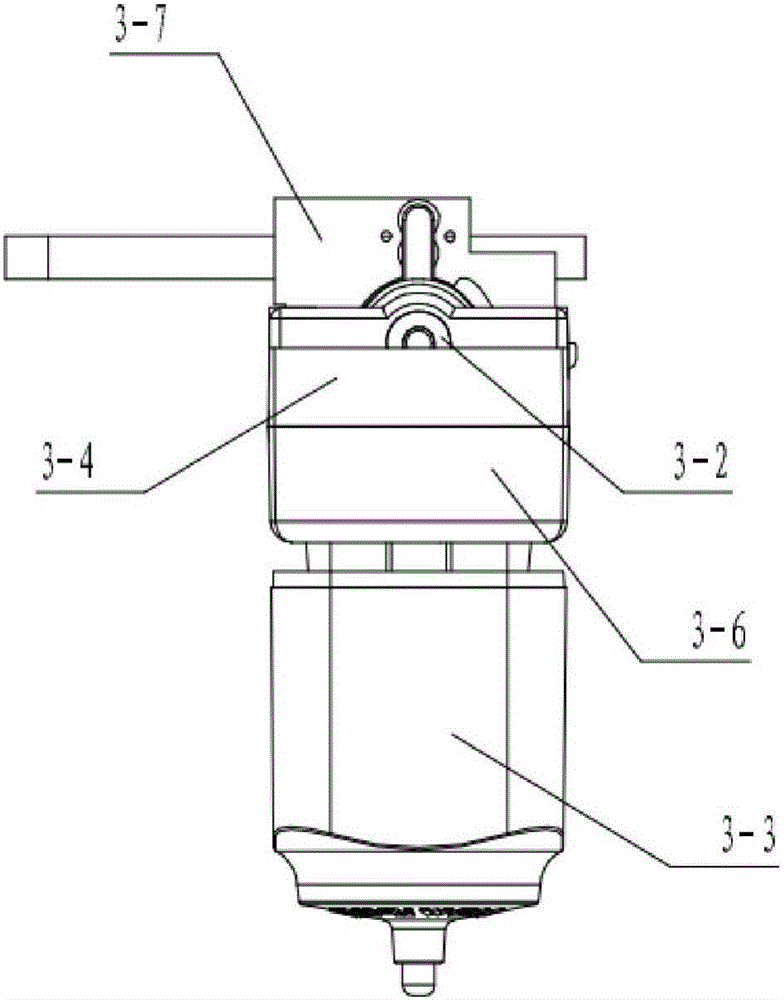

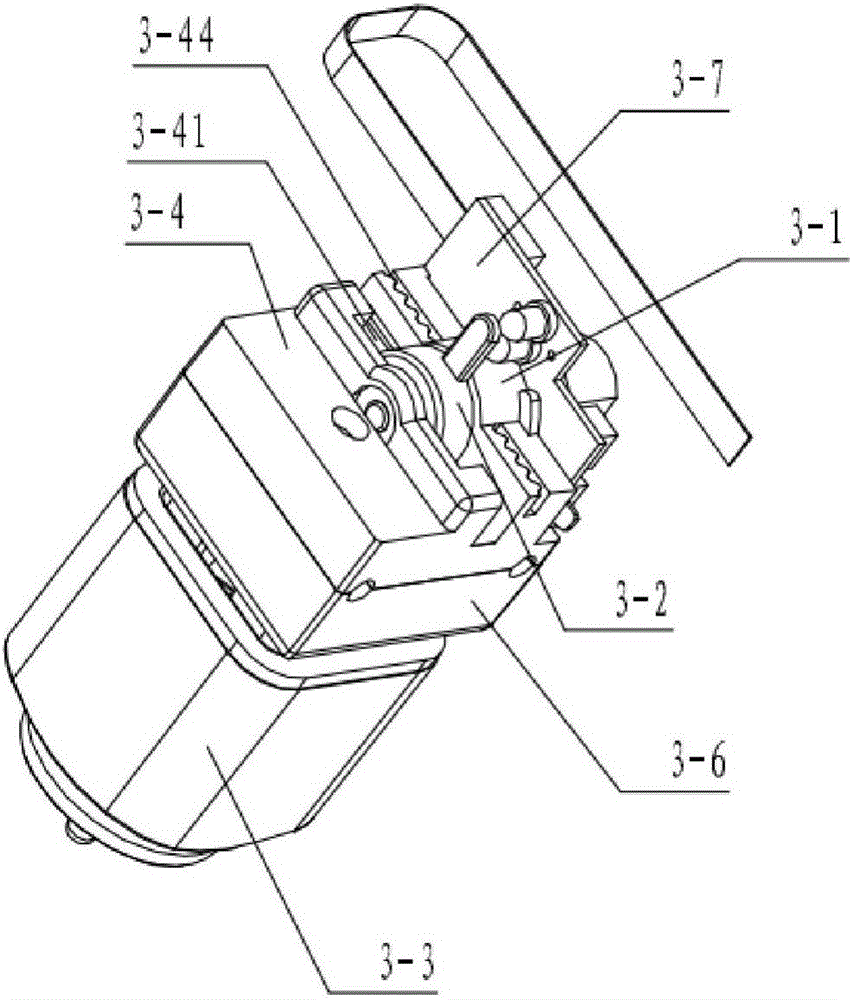

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] This embodiment provides a portable writing machine, the overall shape of which is as follows Image 6 As shown, there is a box-shaped housing, the length and width of which are 14cm, the housing includes an upper cover 1-1, a middle housing 1-2 and a base 1-3, and the upper cover 1-1 has a USB interface, Operation button and display screen, the bottom of base 1-3 has walking wheel, and base middle part is provided with writing window, and organic frame (ie frame) is installed in housing. Of course, the length and width of the writing machine housing can be designed according to needs, and the preferred length and width are all no more than 20cm in a portable structure.

[0034] Such as Figure 7 with Figure 8 As shown, an organic frame is installed in the space surrounded by the upper cover 1-1, the middle shell 1-2, and the base 1-3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com