Pneumatic monorail crane

A monorail crane and track technology, applied in the field of monorail cranes, can solve the problems of exhaust gas pollution, unreliable braking, loud noise, etc., and achieve the effects of reliable working gas path, safe braking and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

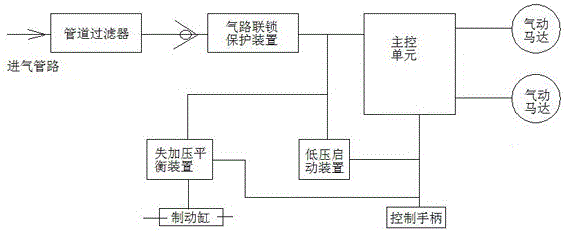

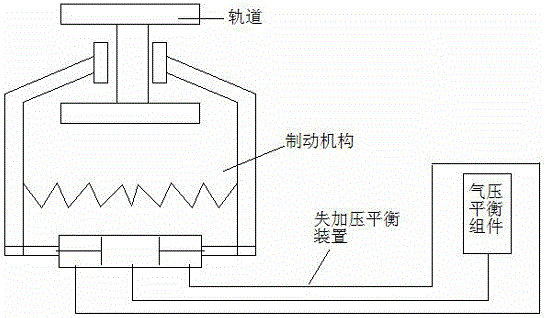

[0017] The existing pneumatic monorail cranes are mainly produced by German technology or Czech technology. Since the pneumatic monorail crane does not need power supply, has no pollution, and there is an underground gas source, it is a product worth promoting in terms of cost and safety. Existing technologies, mainly the leading technologies and products led by the above-mentioned countries, have many problems. Therefore, the present invention provides a pneumatic monorail crane, such as figure 1 , 2 As shown, it includes a track installed on the top of the roadway, a traction head installed on the track and connected in sequence, a number of lifting devices, and a braking mechanism. Air pipeline, one end of the air intake pipeline is connected to the air source, and the other end is sequentially installed with a pipeline filter, a one-way valve, and an air circuit interlock protection device. The air circuit interlock protection device outputs the air source to the main cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com