Advanced treatment system for biorefractory wastewater of industrial park

An industrial park, advanced treatment technology, applied in special compound water treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as defects, reduce dosage, save operating costs, and improve biochemical properties sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

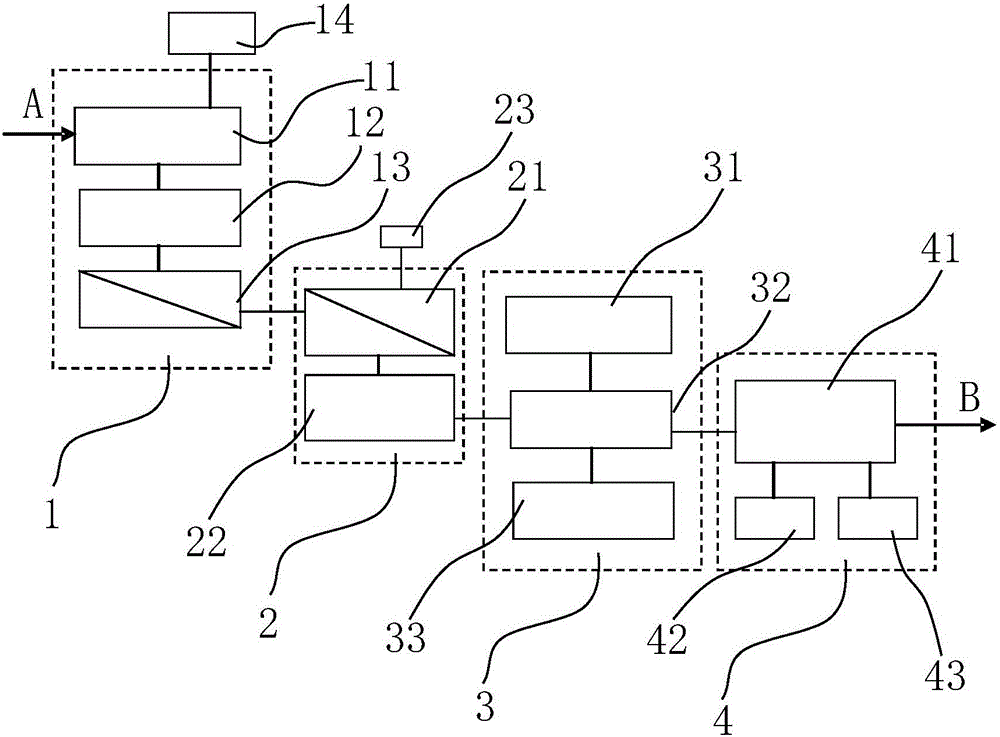

[0045] This embodiment provides an advanced treatment process for refractory wastewater in industrial parks, see figure 1 , the system includes: coagulation sedimentation system, filtration system, advanced oxidation system, biochemical system;

[0046] Among them, the wastewater that has been pretreated by upstream enterprises and reaches a certain standard is discharged into the park’s sewage treatment plant, and the wastewater that has undergone biochemical treatment in the park’s sewage plant to completely remove biochemically degradable organic matter first enters the coagulation and sedimentation system. The coagulant and coagulant make the suspended solids and colloidal compounds of large particles in the water polymerized to a certain weight and then removed by precipitation, and then the suspended solids and colloidal substances are further removed by filtration to ensure that the suspended solids entering the advanced oxidation reaction tank are less than 10mg / L, to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com